Abstract

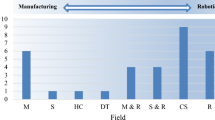

Objective: A systematic literature review was conducted to identify relevant ergonomic and safety factors for designing collaborative workspaces in industrial settings. Background: The growing use of smart and collaborative robots in manufacturing brings some challenges for the human-robot interaction design. Human-centered manufacturing solutions will improve physical and mental well-being, performance, productivity and sustainability. Method: A systematic review of the literature was performed based on the protocol of Preferred Reporting Items for Systematic Reviews and Meta-Analyses. Results: After a search in the databases Scopus and Web of Science, applying inclusion and exclusion criteria, 33 publications in the English language, published between the years 2010 and 2020, remained in the final analysis. Publications were categorized in cognitive ergonomic factors (13), safety factors (10), physical ergonomic factors (6) and organizational ergonomic factors (4). The analysis of results reinforced that to optimize the design of collaborative workstations it is imperative to have a holistic perspective of collaboration, integrating multiple key factors from areas such as engineering, ergonomics, safety, sociology and psychological as well as manufacturing efficiency and productivity. Application: Considering the advantages of the use of cobots in manufacturing, the results of this review will be useful to support companies in implementing human-robot collaboration.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Beetz, M., Bartels, G., Albu-Schaffer, A., Balint-Benczedi, F., Belder, R., Bebler, D., Haddadin, S., Maldonado, A., Mansfeld, N., Wiedemeyer, T., Weitschat, R., Worch, J.H.: Robotic agents capable of natural and safe physical interaction with human co-workers. In: IEEE International Conference on Intelligent Robots and Systems, pp. 6528–6535 (2015). https://doi.org/10.1109/IROS.2015.7354310

Bröhl, C., Nelles, J., Brandl, C., Mertens, A., Schlick, C.M.: TAM reloaded: a technology acceptance model for human-robot cooperation in production systems. In: Stephanidis, C. (eds.) HCI International 2016 - Posters’ Extended Abstracts. HCI 2016. Communications in Computer and Information Science, vol. 617, pp. 97–103. Springer, Cham (2016). https://doi.org/10.1007/978-3-319-40548-3_16

Changizi, A., Dianatfar, M., Lanz, M.: Comfort design in human robot cooperative tasks. In: Ahram, T., Karwowski, W., Taiar, R. (eds.) International Conference on Human Systems Engineering and Design: Future Trends and Application, vol. 876, pp. 521–526. Springer, Cham (2019). https://doi.org/10.1007/978-3-030-02053-8_79

Claes, D., Tuyls, K.: Human Robot-Team Interaction. In: Headleand, C., Teahan, W., Ap Cenydd, L. (eds.) Artificial Life and Intelligent Agents. ALIA 2014. Communications in Computer and Information Science, vol. 519, pp. 61–72. Springer, Cham (2015). https://doi.org/10.1007/978-3-319-18084-7_5

Correia Simões, A., Lucas Soares, A., Barros, A.C.: Factors influencing the intention of managers to adopt collaborative robots (cobots) in manufacturing organizations. J. Eng. Technol. Manage. - JET-M 57(May), 101574 (2020). https://doi.org/10.1016/j.jengtecman.2020.101574

Costa Mateus, J.E., Claeys, D., Limère, V., Cottyn, J., Aghezzaf, E.H.: Ergonomic and performance factors for human-robot collaborative workplace design and evaluation. IFAC PapersOnLine 52(13), 2550–2555 (2019). https://doi.org/10.1016/j.ifacol.2019.11.590

Darvish, K., Wanderlingh, F., Bruno, B., Simetti, E., Mastrogiovanni, F., Casalino, G.: Flexible human-robot cooperation models for assisted shop-floor tasks. Mechatronics 51(2018), 97–114 (2018). https://doi.org/10.1016/j.mechatronics.2018.03.006

Desai, M., Kaniarasu, P., Medvedev, M., Steinfeld, A., Yanco, H.: Impact of robot failures and feedback on real-time trust. In: 8th ACM/IEEE International Conference on Human-Robot Interaction, 2013, pp. 251–258 (2013). https://doi.org/10.1109/HRI.2013.6483596

EU-OSHA: Digitalisation and occupational safety and health (2019, December). https://osha.europa.eu/en/publications/digitalisation-and-occupational-safety-and-health-osh-eu-osha-research-programme/view

Faber, M., Kuz, S., Mertens, A., Schlick, C.M.: Model-based evaluation of cooperative assembly processes in human-robot collaboration. In: Schlick, C., Trzcieliński, S. (eds.) Advances in Ergonomics of Manufacturing: Managing the Enterprise of the Future. Advances in Intelligent Systems and Computing, vol. 490, pp. 27–31. Springer, Cham (2016). https://doi.org/10.1007/978-3-319-41697-7_10

Giuliani, M., Knoll, A.: Using embodied multimodal fusion to perform supportive and instructive robot roles in human-robot interaction. Int. J. Soc. Robot. 5(3), 345–356 (2013). https://doi.org/10.1007/s12369-013-0194-y

Gualtieri, L., Palomba, I., Wehrle, E., Vidoni, R.: The opportunities and challenges of SME manufacturing automation: safety and ergonomics in human-robot collaboration. In: Matt, D., Modrák, V., Zsifkovits, H. (eds.) Industry 4.0 for SMEs: Challenges, Opportunities and Requirements, pp. 105–144. Springer Nature Switzerland AG (2020). https://doi.org/10.1007/978-3-030-25425-4_4

IEA: What is ergonomics? (n.d.). https://iea.cc/what-is-ergonomics/. Accessed May 11 of 2021

Jocelyn, S., Burlet-Vienney, D., Giraud, L.: Experience feedback on implementing and using human-robot collaboration in the workplace. Proc. Hum. Factors Ergon. Soc. 61(1), 1690–1694 (2017). https://doi.org/10.1177/1541931213601911

Kim, W., Lee, J., Peternel, L., Tsagarakis, N., Ajoudani, A.: Anticipatory robot assistance for the prevention of human static joint overloading in human-robot collaboration. IEEE Robot. Autom. Lett. 3(1), 68–75 (2018). https://doi.org/10.1109/LRA.2017.2729666

Kim, W., Kim, N., Lyons, J.B., Nam, C.S.: Factors affecting trust in high-vulnerability human-robot interaction contexts: a structural equation modelling approach. Appl. Ergon. 85(2020), 103056 (2020). https://doi.org/10.1016/j.apergo.2020.103056

Kumar, S., Sahin, F.: A framework for an adaptive human-robot collaboration approach through perception-based real-time adjustments of robot behavior in industry. In: 12th System of Systems Engineering Conference, 2017, pp. 1–6 (2017). https://doi.org/10.1109/SYSOSE.2017.7994967

Lamon, E., De Franco, A., Peternel, L., Ajoudani, A.: A capability-aware role allocation approach to industrial assembly tasks. IEEE Robot. Autom. Lett. 4(4), 3378–3385 (2019). https://doi.org/10.1109/LRA.2019.2926963

Liau, Y.Y., Ryu, K.: Task allocation in human-robot collaboration (HRC) based on task characteristics and agent capability for mold assembly. Procedia Manuf. 51(2019), 179–186 (2020). https://doi.org/10.1016/j.promfg.2020.10.026

Liu, C., Hamrick, J.B., Fisac, J.F., Dragan, A.D., Hedrick, J.K., Sastry, S.S., Griffiths, T.L.: Goal inference improves objective and perceived performance in human-robot collaboration. In: Proceedings of the 2016 International Conference on Autonomous Agents & Multiagent Systems, pp. 940–948 (2016)

Losey, D.P., O’Malley, M.K.: Enabling robots to infer how end-users teach and learn through human-robot interaction. IEEE Robot. Autom. Lett. 4(2), 1–8 (2019). https://doi.org/10.1109/LRA.2019.2898715

Marvel, J.A., Bagchi, S., Zimmerman, M., Antonishek, B.: Towards effective interface designs for collaborative HRI in manufacturing. ACM Trans. Hum. Robot Interact. 9(4), 1–5 (2020). https://doi.org/10.1145/3385009

McGhan, C.L.R., Atkins, E.M.: Human productivity in a workspace shared with a safe robotic manipulator. J. Aerosp. Inf. Syst. 11(1), 1–18 (2014). https://doi.org/10.2514/1.54993

Meziane, R., Li, P., Otis, M.J.D., Ezzaidi, H., Cardou, P.: Safer hybrid workspace using human-robot interaction while sharing production activities. In: IEEE International Symposium on Robotic and Sensors Environments (ROSE) Proceedings, 2014, pp. 37–42 (2014). https://doi.org/10.1109/ROSE.2014.6952980

Michalos, G., Karagiannis, P., Makris, S., Tokçalar, Ö., Chryssolouris, G.: Augmented reality (AR) applications for supporting human-robot interactive cooperation. In: 48th CIRP Conference on Manufacturing Systems, vol. 41, pp. 370–375 (2016). https://doi.org/10.1016/j.procir.2015.12.005

Moher, D., Liberati, A., Tetzlaff, J., Altman, D.G., Group, T.P.: Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. PLOS Med. 6(7), e1000097 (2009). https://doi.org/10.1371/journal.pmed.1000097

Müller, R., Vette, M., Scholer, M.: Inspector robot - a new collaborative testing system designed for the automotive final assembly line. In: 5th CATS 2014 - CIRP Conference on Assembly Technologies and Systems, vol. 23, pp. 59–64 (2014). https://doi.org/10.1016/j.procir.2014.10.093

Oliff, H., Liu, Y., Kumar, M., Williams, M.: Integrating intelligence and knowledge of human factors to facilitate collaboration in manufacturing. In: Proceedings of the ASME 2018 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, pp. 1–10 (2018). https://doi.org/10.1115/detc2018-85805

Oyekan, J.O., Hutabarat, W., Tiwari, A., Grech, R., Aung, M.H., Mariani, M.P., López-Dávalos, L., Ricaud, T., Singh, S., Dupuis, C.: The effectiveness of virtual environments in developing collaborative strategies between industrial robots and humans. Robot. Comput. Integr. Manuf. 55(2019), 41–54 (2019). https://doi.org/10.1016/j.rcim.2018.07.006

Pang, G., Deng, J., Wang, F., Zhang, J., Pang, Z., Yang, G.: Development of flexible robot skin for safe and natural human-robot collaboration. Micromachines 9(576), 1–15 (2018). https://doi.org/10.3390/mi9110576

Pearce, M., Mutlu, B., Shah, J., Radwin, R.: Optimizing makespan and ergonomics in integrating collaborative robots into manufacturing processes. IEEE Trans. Autom. Sci. Eng. 15(4), 1772–1784 (2018). https://doi.org/10.1109/TASE.2018.2789820

Rabby, K.M., Khan, M., Karimoddini, A., Jiang, S.X.: An effective model for human cognitive performance within a human-robot collaboration framework. In: Conference Proceedings - IEEE International Conference on Systems, Man and Cybernetics, 2019, pp. 3872–3877 (2019). https://doi.org/10.1109/SMC.2019.8914536

Reinhardt, J., Pereira, A., Beckert, D., Bengler, K.: Dominance and movement cues of robot motion: a user study on trust and predictability. In: IEEE International Conference on Systems, Man, and Cybernetics, 2017, pp. 1493–1498 (2017). https://doi.org/10.1109/SMC.2017.8122825

Rojas, R.A., Garcia, M.A.R., Wehrle, E., Vidoni, R.: A variational approach to minimum-jerk trajectories for psychological safety in collaborative assembly stations. IEEE Robot. Autom. Lett. 4(2), 823–829 (2019). https://doi.org/10.1109/LRA.2019.2893018

Romero D., Mattsson S., Fast-Berglund, Å., Wuest T., Gorecky D., Stahre J.: Digitalizing occupational health, safety and productivity for the operator 4.0. In: Moon, I., Lee, G., Park, J., Kiritsis, D., von Cieminski, G. (eds.) Advances in Production Management Systems. Smart Manufacturing for Industry 4.0. APMS 2018. IFIP Advances in Information and Communication Technology, vol. 536. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-99707-0_59

Sadrfaridpour, B., Saeidi, H., Burke, J., Madathil, K., Wang, Y.: Modeling and control of trust in human-robot collaborative manufacturing. In: Mittu, R., Sofge, D., Wagner, A., Lawless, W. (eds.) Robust Intelligence and Trust in Autonomous Systems, pp. 115–142. Springer, Boston (2016). https://doi.org/10.1007/978-1-4899-7668-0_7

Sadrfaridpour, B., Wang, Y.: Collaborative assembly in hybrid manufacturing cells: an integrated framework for human-robot interaction. IEEE Trans. Autom. Sci. Eng. 15(3), 1178–1192 (2018). https://doi.org/10.1109/TASE.2017.2748386

Safeea, M., Mendes, N., Neto, P.: Minimum distance calculation for safe human robot interaction. Procedia Manuf. 11(2017), 99–106 (2017). https://doi.org/10.1016/j.promfg.2017.07.157

Schulz, R., Kratzer, P., Toussaint, M.: Preferred interaction styles for human-robot collaboration vary over tasks with different action types. Front. Neurorobotics 12(36), 1–13 (2018). https://doi.org/10.3389/fnbot.2018.00036

Tian, Y., Chen, Z., Jia, T., Wang, A., Li, L.: Sensorless collision detection and contact force estimation for collaborative robots based on torque observer. In: Proceedings of the 2016 IEEE International Conference on Robotics and Biomimetics, 2016, pp. 946–951 (2016). https://doi.org/10.1109/ROBIO.2016.7866446

Unhelkar, V.V., Lasota, P.A., Tyroller, Q., Buhai, R.D., Marceau, L., Deml, B., Shah, J.A.: Human-aware robotic assistant for collaborative assembly: integrating human motion prediction with planning in time. IEEE Robot. Autom. Lett. 3(3), 2394–2401 (2018). https://doi.org/10.1109/LRA.2018.2812906

Wang, Y., Lematta, G.J., Hsiung, C.-P., Rahm, K.A., Chiou, E.K., Zhang, W.: Quantitative modeling and analysis of reliance in physical human-machine coordination. J. Mech. Robot. 11(6), 64–70 (2019). https://doi.org/10.1115/1.4044545

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Pinheiro, S. et al. (2022). Ergonomics and Safety in the Design of Industrial Collaborative Robotics. In: Arezes, P.M., et al. Occupational and Environmental Safety and Health III. Studies in Systems, Decision and Control, vol 406. Springer, Cham. https://doi.org/10.1007/978-3-030-89617-1_42

Download citation

DOI: https://doi.org/10.1007/978-3-030-89617-1_42

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-89616-4

Online ISBN: 978-3-030-89617-1

eBook Packages: EngineeringEngineering (R0)