Abstract

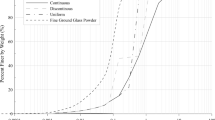

To be more sustainable in the road construction industry, the rock-based geopolymer concept should be applied with an aim to create a geopolymer-based road structural layer. This research episode concentrated on the primary study of compaction characteristics of crushed rock geopolymer (CR-GP) in conjunction with its unconfined compressive strength (UCS) and micro-observations through XRF and XRD. The new grain size distribution curve, namely practical grading, was produced for use as a prime material in CR-GP. Especially, CR-GP is a mixture of CR practical grading (B) and liquid alkaline activator (L) of Na2SiO3 (SS) and NaOH (SH) with a concentration value of five molar. The SS/SH ratio of 0.67 was also used. Test results showed that the compaction curves of CR-GP can be established as the bell curve with a peak point. The modified compaction curve showed higher maximum dry density (MDD) of 2210 kg/m3 and optimum liquid alkaline activator content (OLC) of 11%. It was found that higher compactive efforts of the modified compaction, higher densification than that of the standard compaction, corresponding to the compaction theory in soil mechanics. CR-GP having practical grading achieved higher UCS up to the minimum requirement of the normal cement-stabilized road base as a benchmark material. Based on the micro-observation of this research, an applicable level of alkaline solution concentration could dissolve silica (Si), alumina (Al), and calcium (Ca) from crushed rock with the practical crushed rock grading characteristics, leading to an increase in strength up to an appropriate level for the road construction material.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Davidovits J (1991) Geopolymers. J Therm Anal Calorim 37(8):1633–1656

Davidovits J (2013) Geopolymer cement a review. Institute geopolymer, 1–11

Malhotra VN (2002) Introduction sustainable development and concrete technology. ACI Concr Int 24:7–22

Chindaprasirt P, Chareerat T, Sirivivatnanon V (2007) Workability and strength of coarse high calcium fly ash geopolymer. Cement Concr Compos 29(3):224–229

Chindaprasirt P, Jaturapitakkul C, Rattanasak U (2009) Comparative study on the characteristics of fly ash and bottom ash geopolymers. Waste Manag 29(2):539–543

Davidovit J (2015) Geopolymer chemistry and applications, Geopolym. Institute, France

Hardjito D, Wallah SE, Sumajouw DMJ, Ranga BV (2004) Brief review of development of geopolymer concrete/interviewer: G. H. Symposium. American Concrete Institute, USA, Los Vegas

Rattanasak U (2018) Geopolymer. Thailand concrete asso, Thailand

Hoy M, Horpibulsuk S, Rachan R, Arulrajah A (2016) Recycled asphalt pavement—fly ash geopolymers as a sustainable pavement base material: strength and toxic leaching investigations. Sci Total Environ 573:19–26

Horpibulsuk S, Hoy M, Witchayaphong P, Rachan R, Arulrajah A (2017) Recycled asphalt pavement—fly ash geopolymer as a sustainable stabilized pavement material. Mater Sci Eng 273:1–10

Deventer VSJ, Provis JL, Duxson P (2012) Technical and commercial progress in the adoption of geopolymer cement. Miner Eng 29:89–104

ASTM C618-19 (2015) Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM International, West Conshohocken, PA

Sukmak P, Horpibulsuk S, Shen S-L (2013) Strength development in clay–fly ash geopolymer. Constr Build Mater 40:566–574

Wattanachai P, Suwan T (2017) Strength of geopolymer cement curing at ambient temperature by non-oven curing approaches: an overview. In: The 4th international conference on manufacturing and industrial technologies, materials science and engineering, pp 1–6

Adhikari S, Khattak JM, Adhikari B (2018) Mechanical characteristics of Soil-RAP-Geopolymer mixtures for road base and subbase layers. Int J Pavement Eng 1–14

Boonjaeng S, Chindaprasirt P, Pimraksa K (2014) Lime-calcined clay materials with alkaline activation: phase development and reaction transition zone. Appl Clay Sci 95:357–364s

Acknowledgements

The first author wishes to express gratitude to the Thailand Research Fund (TRF) scheme ‘TRF Research Career Development Grant (2016–2018)’ for the financial support of this project (RSA5980070). Moreover, the research team of the Civil Engineering Department at Naresuan University, Chiang Mai University, and Khon Kaen University, Thailand, are also gratefully acknowledged for providing overview guidance and valuable inputs into this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Jitsangiam, P., Suwan, T., Nusit, K., Chindaprasirt, P., Kwunjai, S. (2022). Crushed Rock Geopolymer as a Future Road Construction Material: An Evaluation of Compaction and Strength Characteristics. In: Tutumluer, E., Nazarian, S., Al-Qadi, I., Qamhia, I.I. (eds) Advances in Transportation Geotechnics IV. Lecture Notes in Civil Engineering, vol 164. Springer, Cham. https://doi.org/10.1007/978-3-030-77230-7_24

Download citation

DOI: https://doi.org/10.1007/978-3-030-77230-7_24

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-77229-1

Online ISBN: 978-3-030-77230-7

eBook Packages: EngineeringEngineering (R0)