Abstract

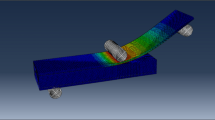

Three different experimental methods used in fracture testing sandwich panels are studied in the context of providing an assessment of face sheet-to-core interface strength. For this reason, strain energy release rate (ERR), complex stress intensity factors (SIFs) and mode mixity phase angle are computed. The analytical models exploit both the framework of linear elastic fracture mechanics (LEFM) in a combination of analytical considerations and numerical results and one-dimensional (1D) beam theories, whereas the finite element predictions are conducted using the capabilities of the ABAQUS package and a standalone subroutine developed in MATLAB environment for post-processing the results of two-dimensional (2D) finite element analysis. The results presented in this research allow drawing conclusions on the accuracy of fracture analysis predictions for each of the three different specimens by comparing 2D numerical calculations with semi-analytical results and 1D analytical solutions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

ABAQUS: User’s Manual, ver. 2016. Dassault Systémes Simulia Corp., Providence, RI, USA (2016)

Adams, D.O., Nelson, J., Bluth, Z.: Development and evaluation of fracture mechanics test methods for sandwich composites. In: Proceedings of the 2012 Aircraft Airworthiness and Sustainment Conference, Baltimore, MD, US (2012)

Altenbach, H., Altenbach, J., Kissing, W.: Mechanics of Composite Structural Elements, 2nd edn. Springer (2018)

Amabili, M.: Nonlinear Mechanics of Shells and Plates in Composite Soft and Biological Materials. Cambridge University Press, Cambridge (2018)

Andrews, M.G., Massabò, R.: The effects of shear and near tip deformations on energy release rate and mode mixity of edge-cracked orthotropic layers. Eng. Fract. Mech. 74(17), 2700–2720 (2007)

Avilés, F., Carlsson, L.A.: Analysis of the sandwich DCB specimen for debond characterization. Eng. Fract. Mech. 75(2), 153–168 (2008)

Barbieri, L., Massabò, R., Berggreen, C.: The effects of shear and near tip deformations on interface fracture of symmetric sandwich beams. Eng. Fract. Mech. 201, 298–321 (2018)

Berggreen, C., Saseendran, V., Carlsson, L.: A modified DCB-UBM test method for interfacial fracture toughness characterization of sandwich composites. Eng. Fract. Mech. 203, 208–223 (2018)

Burlayenko, V.N., Sadowski, T.: Dynamic analysis of debonded sandwich plates with flexible core—Numerical aspects and simulation. In: Altenbach, H., Eremeyev, V.A. (eds.) Shell-like Structures: Non-classical Theories and Applications, Advanced Structured Materials, vol. 15, pp. 415–440. Springer, Berlin Heidelberg (2011)

Burlayenko, V.N., Sadowski. T.: Numerical modeling of sandwich plates with partially dedonded skin-to-core interface for damage detection. In: DeRoeck G, Degrande G, Lombaert G, Müller G (eds) Proceedings of the 8th International Conference on Structural Dynamics (EURODYN), pp 2242–2249. Leuven, Belgium (2011b)

Burlayenko, V., Pietras, D., Sadowski, T.: Influence of geometry, elasticity properties and boundary conditions on the mode I purity in sandwich composites. Compos. Struct. 223, 110942 (2019)

Burlayenko, V.N., Altenbach, H., Sadowski, T.: Dynamic fracture analysis of sandwich composites with face sheet/core debond by the finite element method. In: Altenbach, H., Belyaev, A., Eremeyev, V.A., Krivtsov, A., Porubov, A.V. (eds.) Dynamical Processes in Generalized Continua and Structures, Advanced Structured Materials, vol. 103, pp. 163–194. Springer, Cham (2019)

Burlayenko, V.N., Sadowski, T., Pietras, D.: Influence of dynamic loading on fracture behaviour of DCB sandwich specimen. ITM Web Conf. 29, 02003 (2019)

Burlayenko, V.N., Altenbach, H., Dimitrova, S.D.: Interface strength assessments of sandwich panels with a face sheet/core debond. In: Altenbach, H., Chinchaladze, N., Kienzler, R., Müller, W.H. (eds.) Analysis of Shells, Plates, and Beams: A State of the Art Report, pp. 95–122. Springer, Cham (2020)

Burlayenko, V.N., Sadowski, T., Dimitrova, S.D.: Nonlinear fracture dynamic analysis of double cantilever beam sandwich specimens. In: Lacarbonara, W., Balachandran, B., Ma, J., Tenreiro Machado, J.A., Stepan, G. (eds.) New Trends in Nonlinear Dynamics, pp. 89–97. Springer, Cham (2020)

Chatterjee, V.A., Saraswat, R., Verma, S.K., Bhattacharjee, D., Biswas, I., Neogi, S.: Embodiment of dilatant fluids in fused-double-3D-mat sandwich composite panels and its effect on energy-absorption when subjected to high-velocity ballistic impact. Compos. Struct. 249(112), 588 (2020)

Davidson, P., Waas, A.M., Yerramalli, C.S.: Experimental determination of validated, critical interfacial modes I and II energy release rates in a composite sandwich panel. Compos. Struct. 94(2), 477–483 (2012)

Davis, B., Wawrzynek, P., Hwang, C., Ingraffea, A.: Decomposition of 3-D mixed mode energy release rates using the virtual crack extension method. Eng. Fract. Mech. 131, 382–405 (2014)

Farkash, E., Banks-Sills, L.: Quarter-point elements are unnecessary for the VCCT. J. Appl. Mech. 87(8), 081009 (2020)

Fu, Y., Sadeghian, P.: Flexural and shear characteristics of bio-based sandwich beams made of hollow and foam-filled paper honeycomb cores and flax fiber composite skins. Thin-Walled Structures 153, 106834 (2020)

Funari, M.F., Greco, F., Lonetti, P.: Sandwich panels under interfacial debonding mechanisms. Compos. Struct. 203, 310–320 (2018)

Kardomateas, G.A., Berggreen, C., Carlsson, L.A.: Energy-release rate and mode mixity of face/core debonds in sandwich beams. AIAA j. 51(4), 885–892 (2013)

Kardomateas, G.A., Yuan, Z.: Closed form solution for the energy release rate and mode partitioning of the single cantilever beam sandwich debond from an elastic foundation analysis. J. Sandwich Struct. Mater. (2020). https://doi.org/10.1177/1099636220932900

Li, S., Wang, J., Thouless, M.D.: The effects of shear on delamination in layered materials. J. Mech. Phys. Solids 52(1), 193–214 (2004)

Odessa, I., Frostig, Y., Rabinovitch, O.: Modeling of interfacial debonding propagation in sandwich panels. Int. j. Solids Struct. 148–149, 67–78 (2018)

Østergaard, R.C., Sørensen, B.F.: Interface crack in sandwich specimen. Int. j. Fract. 143(4), 301–316 (2007)

Prasad, S., Carlsson, L.A.: Debonding and crack kinking in foam core sandwich beams—I. Analysis of fracture specimens. Eng. Fract. Mech. 47(6), 813–824 (1994)

Quispitupa, A., Berggreen, C., Carlsson, L.A.: On the analysis of a mixed mode bending sandwich specimen for debond fracture characterization. Eng. Fract. Mech. 76(4), 594–613 (2009)

Ratcliffe, J.G., Reeder, J.R.: Sizing a single cantilever beam specimen for characterizing facesheet–core debonding in sandwich structure. J. Compos. Mater. 45(25), 2669–2684 (2011)

Sivaram, A., Manikandan, N., Krishnakumar, S., Rajavel, R., Krishnamohan, S., Vijayaganth, G.: Experimental study on aluminium based sandwich composite with polypropylene foam sheet. Mater. Today Proc. 24, 746–753 (2020)

Sorensen, B., Jorgensen, K., Jacobsen, T., Ostergaard, R.: DCB-specimen with uneven bending moments. Int. j. Fract. 141, 163–176 (2006)

Szekrényes, A.: Mechanics of shear and normal deformable doubly-curved delaminated sandwich shells with soft core. Compos. Struct. 258(15), 113196 (2021)

Ustinov, K.: On semi-infinite interface crack in bi-material elastic layer. Eur. j. Mech. Solids 75, 56–69 (2019)

Yoshida, K., Aoki, T.: Beam on elastic foundation analysis of sandwich SCB specimen for debond fracture characterization. Compos. Struct. 195, 83–92 (2018)

Acknowledgements

The first author would like to mention that this research has been started during his stay at the Institute of Mechanics of Otto-von-Guericke-Universität Magdeburg, which was supported by the German Academic Exchange Service (DAAD) Funding Program ID no.~57440915.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Appendices

Appendix 1

Following the original notations in Østergaard and Sørensen (2007); Andrews and Massabò (2007); Barbieri et al. (2018), the geometrical and material dimensionless parameters of the sandwich beam cross-section are defined as follows:

where \(\overline{E}_{i} = E_{i}\) for plane stress and \(\overline{E}_{i} = \frac{{E_{i} }}{{1 - \nu_{i}^{2} }}\) for plane strain with \(E_{i}\) and \(\nu_{i}^{{}}\) the Young's modulus and the Poisson's ratio of the layer i = {f, c} and the shear modulus, \(G_{i} = \frac{{E_{i} }}{{2(1 + \nu_{i} }})\); α and β stand for the Dundur's parameters with \(\overline{\kappa }_{i} = \frac{{3 - \nu_{i} }}{{1 + \nu_{i} }}\) for plane stress and \(\overline{\kappa }_{i} = 3 - 4\nu_{i}\) for plane strain; \(\varepsilon\) is the oscillatory index.

The dimensionless distance of the neutral axis of the substrate at crack tip cross-section of unit width is defined by

whereas the dimensionless bending stiffnesses of the substrate and fully bonded part (the base) of unit width cross-section are given by

The coefficients in (2.1) are calculated in the forms:

Appendix 2

The positive dimensionless functions \(f_{M} \left( {\Sigma ,\eta } \right)\), \(f_{P} \left( {\Sigma ,\eta } \right)\) and the phase angle \(\gamma_{M} \left( {\Sigma ,\eta } \right)\) define the energy release rates for arbitrary combinations of bending moments and axial forces (Fig. 2b). In terms of the dimensionless parameters they take the form (Barbieri et al. 2018):

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Burlayenko, V.N., Altenbach, H., Dimitrova, S.D. (2021). Debonding Resistance Evaluation in Virtual Testing of Sandwich Specimens. In: Altenbach, H., Amabili, M., Mikhlin, Y.V. (eds) Nonlinear Mechanics of Complex Structures. Advanced Structured Materials, vol 157. Springer, Cham. https://doi.org/10.1007/978-3-030-75890-5_2

Download citation

DOI: https://doi.org/10.1007/978-3-030-75890-5_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75889-9

Online ISBN: 978-3-030-75890-5

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)