Abstract

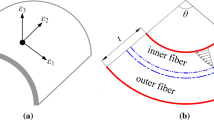

The VDA 238-100 tight radius bend test has received significant attention from industry over the past decade because it provides a proportional plane strain–plane stress state until fracture. It will be demonstrated that the adoption of the vertical punch force as the unique metric for failure detection can lead to false positives. The punch force will reduce at large bend angles due to the mechanics of the test even in the absence of material failure. Two novel detection methods based on the nominal principal stress and the plastic work were evaluated on six different steel grades with a nominal ultimate tensile strength of approximately 590 MPa. Three 590R advanced high-strength steels provided by three different suppliers and three variants of the Ductibor® 500 are studied. The stress-based metric can be seen as an improvement over the VDA 238-100 load methodology since it accounts for thinning of the specimen cross-section and can identify false positives when the material forms a full bend in the absence of fracture but drops at bend angles greater than 160°. For performance ranking of materials with the same strength level, the plastic work metric is found to be sufficiently sensitive to distinguish between various 590 MPa steel grades since the material hardening rate is directly embedded.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Stoughton TB, Yoon JW (2011) A new approach for failure criterion for sheet metals. Int J Plast 27:440–459. https://doi.org/10.1016/j.ijplas.2010.07.004

Mohr D, Henn S (2007) Calibration of stress-triaxiality dependent crack formation criteria: a new hybrid experimental-numerical method. J Exper Mech 47:805–820. https://doi.org/10.1007/s11340-007-9039-7

Dunand M, Mohr D (2010) Hybrid experimental-numerical analysis of basic ductile fracture experiments for sheet metals. Int J Solids Struct 47:1130–1143. https://doi.org/10.1016/j.ijsolstr.2009.12.011

Pack K, Ahn K, Huh H, Lou Y (2014) Fracture modelling of DP780 sheets using a hybrid experimental-numerical method and two-dimensional digital image correlation. Int J Mater Product Technol 48, https://doi.org/10.1504/IJMPT.2014.059029

VDA 238-100 (2010) Test specification: plate bending test for metallic materials

VDA 238-100 (2017) Test specification: plate bending test for metallic materials

Cheong K, Omer K, Butcher C, George R, Dykeman J (2017) Evaluation of the VDA 238-100 tight radius bending test using digital image correlation strain measurements. IOP Conf Ser J Phys

Noder J, Butcher C, Dykeman J (2020) New methodlogies for Fracture Detection of Automotive Steels in Tight Radius Bending: Application to the VDA 238-100 V-Bend Test. J Exp Mech. https://doi.org/10.1007/s11340-020-00627-z

Cheong K, Butcher C, Dykeman J (2018) The influence of the through-thickness strain gradients on the fracture characterization of advanced high-strength steels. SAE Int J Mater Manuf 11(4). https://doi.org/10.4271/2018-01-0627

International Organization for Standardization, (2008). ISO/DIC 12004-2:2008. Metallic materials sheet and strip —Determination of forming limit curves—Part 2: determination of forming limit curves in the laboratory

Troive L (2017) New method for evaluation of bend ability based on three-point-bending and the evolution of the cross-section moment. IOP Conf Ser J Phys 896(2017)

Hill R (1950) Mathematical theory of plasticity. Oxford University Press

Larour P, Hackl B, Leomann F (2013) Sensitivity analysis on the calculated bending angle in the instrumented bending test. IDDRG conference, Zurich, Switzerland

Acknowledgments

Financial support for this study was provided in part by the Natural Sciences and Engineering Research Council of Canada, the American Iron and Steel Institute (AISI), and Honda Research Americas (HRA). The authors would particularly like to thank Willie Bernert and Chris Brown from ArcelorMittal, Dr. Hesham Ezzat of AISI, and Dr. Kishore Pydimarry of HRA for their support of the project. We would also like to gratefully acknowledge Kenneth Cheong from the University of Waterloo for his valuable discussion on V-bend experiments.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Noder, J. et al. (2021). New Methods for Fracture Detection of Automotive Steels. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_55

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_55

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)