Abstract

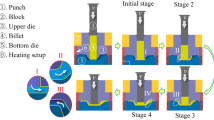

Magnesium alloy cylindrical parts with inner ribs (MACPIR) are attractive as lightweight components for improving the performance of high-end equipment in various industrial sectors. Induction-heating-assisted spinning (IHAS), an effective way to manufacture cylindrical parts made of difficult-to-deform materials, was used to form the MACPIR. However, when using this process for MACPIR, nonuniform deformation and other forming defects can easily occur between the cylindrical wall and inner ribs. A FEM model of MACPIR during IHAS was developed via ABAQUS, and experimental verification was conducted. Forming defects that occurred during the spinning process of MACPIR were analyzed, and evaluation indexes of forming quality were proposed. The results show that the concavity of rib back, and nonuniform distribution of rib height along tangential and axial directions are the main forming defects. Additionally, the influence of process parameters on the forming quality was discussed. The results indicate that the forming quality of MACPIR can be improved under a forming temperature of T = 300 ~ 350 ℃, roller feed rate f = 0.4 ~ 0.6 mm/r, and thinning ratio of wall thickness Ψt = 65 ~ 75%. The simulation results confirm well with experimental ones.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Liu BY, Liu F, Yang N, Zhai XB, Zhang L, Yang Y, Li B, Li J, Ma E, Nie JF, Shan ZW (2019) Large plasticity in magnesium mediated by pyramidal dislocations. Science 365(6448):73–75

Luo W, Chen F, Xu BB, Yang ZJ, Guo YM, Lu B, Huang T (2018) Study on compound spinning technology of large thin-walled parts with ring inner ribs and curvilinear generatrix. Int J Adv Manuf Technol 98(5–8):1199–1216

Zeng X, Fan XG, Li HW, Zhan M, Gao PF, Chen Q (2019) Recent developments in spinning of complex thin-walled parts with inner ribs. J Netshape Form Eng 11(5):21–31 (in Chinese)

Hadadzadeh A, Wells MA (2017) Analysis of the hot deformation of ZK60 magnesium alloy. J Magn Alloys 5(4):369–387

Xia QX, Long JC, Yuan S, Cheng XQ (2019) Numerical investigation on the material flow of magnesium alloy cylindrical parts with inner ribs during hot power spinning. Paper presented at the 13th International Conference on Numerical Methods in Industrial Forming Processes, Portsmouth, New Hampshire, 23–27 June 2019

Jiang SY, Zheng YF, Ren ZY, Li CF (2009) Multi-pass spinning of thin-walled tubular part with longitudinal inner ribs. Trans Nonferrous Met Soc China 19(1):215–221

Xia QX, Yang MH, Hu Y, Cheng XQ (2006) Numerical simulation and experimentation cup-shaped thin-walled inner rectangular gear formed by spinning. Chin J Mech Eng 42(12):192–196 (in Chinese)

Zhang YL, Wang FH, Dong J, Jin L, Liu CH, Ding WJ (2018) Grain refinement and orientation of AZ31B magnesium alloy in hot flow forming under different thickness reductions. J Mater Sci Technol 34(7):1091–1102

Dong S, Yu Q, Jiang YY, Dong J, Wang FH, Jin L, Ding WJ (2017) Characteristic cyclic plastic deformation in ZK60 magnesium alloy. Int J Plast 91:25–47

Xia QX, Long JC, Xiao GF, Cheng XQ (2019) Constitutive model of extruded ZK61 magnesium alloy at high temperature considering compensation of strain. Paper presented at the 16th National Annual Conference on Plastic Engineering, Taiyuan, Shanxi, 18–20 October 2019

Xia QX, Yuan S, Long JC, Huang GZ, Cheng XQ (2019) Microstructure evolution of magnesium alloy cylindrical parts with inner ribs during hot power spinning. Paper presented at the 2nd Asian Pacific Symposium on Technology of Plasticity. Tokyo, Japan, 31 July-3 August 2019

Xia QX, Li XM, Li XL, Zhou C, Zhang SJ (2008) Experimental research and numerical simulation on cup-shaped thin-walled trapezoidal inner gear formed by spinning. Forg Stamp Technol 33(6):57–62 (in Chinese)

Xia QX, Hu Y, Sun LY, Ye BY (2007) Numerical simulation of influence of roller working surface on spin forming of rectangular inner meshing gear. J S China Univ Technol Nat Sci Ed 35(8):1–6 (in Chinese)

JB/T9177-1999. Structural main factors for steel die forgings

Xia QX, Long JC, Zhu NY, Xiao GF (2019) Research on the microstructure evolution of Ni-based superalloy cylindrical parts during hot power spinning. Adv Manuf 7(1):52–63

Li JQ, Liu J, Cui ZS (2014) Characterization of hot deformation behavior of extruded ZK60 magnesium alloy using 3D processing maps. Mater Des 56:889–897

Xiao GF, Zhu NY, Long JC, Xia QX, Chen WP (2018) Research on precise control of microstructure and mechanical properties of Ni-based superalloy cylindrical parts during hot backward flow spinning. J Manuf Process 34:140–147

Acknowledgments

This project is financially supported by National Natural Science Foundation of China (No. 51775194). One of the authors, Jinchuan Long, also would like to acknowledge financial support from the Chinese Scholarship Council (CSC).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Xia, Q., Long, J., Huang, G., Yuan, S., Qin, Y. (2021). A Study of the Forming Quality of Magnesium Alloy Cylindrical Parts with Inner Ribs by Induction-Heating-Assisted Spinning. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_28

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_28

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)