Abstract

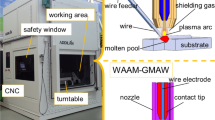

The use of low transformation temperature (LTT) alloys seems to be a promising way for reducing the residual stress level of fusion welded components. Wire and arc additive manufacturing (WAAM) is a high performance additive manufacturing process for generating large metallic components, which is based on common arc welding processes. The following article describes the investigations regarding generating LTT alloys in WAAM through in-situ alloying. Therefor a multi wire gas metal arc process in spray transfer mode is being used to generate the target LTT alloy. By using two high alloyed cold wires, it was possible to reach a chemical composition for LTT alloys, proposed by Steven and Haynes. The process showed stable behavior and it was possible to build up test specimen in form of wall shaped structures of 15 mm height. By establishing in-situ alloying for the additive manufacturing of LTTs a new field of investigations regarding the structural behavior of LTT-injected components is being opened.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Pan, Z., Ding, D., Wu, B., Cuiuri, D., Li, H., Norrish, J.: Arc welding processes for additive manufacturing: a review. In: Chen, S., Zhang, Y., Feng, Z., et al. (eds.) Transactions on Intelligent Welding Manufacturing. Springer, Singapore, pp. 3–24 (2018). ISBN 978-981-10-5354-2

Ding, D., Pan, Z., Cuiuri, D., Li, H.: Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 81(1–4), 465–481 (2015). ISSN 0268-3768. Verfügbar unter: https://doi.org/10.1007/s00170-015-7077-3

Norsk Titanium - Unternehmenswebseite [online] [Zugriff am: 05.09.17]. Verfügbar unter: https://www.norsktitanium.com/

Wegener, V.: Ramlab - Unternehmenswebsite [online] [Zugriff am: 5. September 2017]. Verfügbar unter: https://ramlab.com/

Piehl, K.H.: Formgebendes Schweissen von Schwerkomponenten. Thyssen, Technische Berichte 1989(21, 1), 53–71 (1989)

Steven, W., Haynes, A.G.: The temperature of formation of Martensite and Bainite in low-alloy steel. J. Iron Steel Inst. 183, 349–359 (1956)

Kromm, A.: Umwandlungsverhalten und Eigenspannungen beim Schweißen neuartiger LTT-Zusatzwerkstoffe. Bundesanstalt für Materialforschung und -prüfung (BAM). BAM-Dissertationsreihe, Berlin. 72 (2011). ISBN 978-3-9813853-9-7

Kromm, A., Kannengiesser, T.: Characterizing PHASE TRANSFORMATIONS of different LTT alloys and their effect on RESIDUAL STRESSES and COLD CRACKING [online]. Weld. World 55(3–4), 48–56 (2011). ISSN 0043-2288. Verfügbar unter: https://doi.org/10.1007/BF03321286

Gach, S., Olschok, S., Arntz, D., Reisgen, U.: Erratum: residual stress reduction of laser beam welds by use of low-transformation temperature (LTT) filler materials in carbon Manganese steels— in situ diagnostic: image correlation. J. Laser Appl. 30, 032416 (2018) [online]. J. Laser Appl. 32(1), 19901 (2020). ISSN 1042–346X. Verfügbar unter: https://doi.org/10.2351/1.5133938

Reisgen, U., Olschok, S., Gach, S.: Nutzung von Low-Transformation-Temperature-Werkstoffen (LTT) zur Eigenspannungsreduzierung im Elektronenstrahlschweißprozess [online]. Materialwissenschaft und Werkstofftechnik 47(7), 589–599 (2016). ISSN 09335137. Verfügbar unter: https://doi.org/10.1002/mawe.201600549

Oster, L., Akyel, F., Reisgen, U., Olschok, S., et al.: Investigating plasma keyhole welding with multiple wires for fusion welding with chemically graded weld seams (2019)

Mochizuki, M., Matsushima, S., Toyoda, M., Morikage, Y., Kubo, T.: Study of residual stress reduction in welded joints using phase transformation behaviour of welding material. Studies on numerical simulation of temperature, microstructure, and thermal stress histories during welding and their application to welded structures (2 nd report) [online]. Weld. Int. 19(10), 773–782 (2005). ISSN 0950-7116. Verfügbar unter: https://doi.org/10.1533/wint.2005.3491

Kromm, A., Kannengiesser, T.: Effect of martensitic phase transformation on stress build-up during multilayer welding [online]. Mater. Sci. Forum: 768–769, 660–667 (2013). Verfügbar unter:https://doi.org/10.4028/www.scientific.net/MSF.768-769.660

Kitano, H., Nakamura, T.: Distortion reduction of parts made by wire and arc additive manufacturing technique using low transformation temperature welding materials [online]. Q. J. Jpn. Weld. Society 36(1), 31–38 (2018). ISSN 0288-4771. Verfügbar unter: https://doi.org/10.2207/qjjws.36.31

Acknowledgments

The presented investigations were carried out at RWTH Aachen University Welding and Joining Institute ISF within the framework of the Collaborative Research Centre SFB1120–236616214 “Bauteilpräzision durch Beherrschung von Schmelze und Erstarrung in Produktionsprozessen” and funded by the Deutsche Forschungs-gemeinschaft e.V. (DFG, German Research Foundation). The sponsorship and support is gratefully acknowledged.

Special thanks also go to the companies ESAB AB and EWM AG for providing welding consumables and welding machines.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Reisgen, U., Sharma, R., Oster, L. (2021). In-Situ Alloying in Gas Metal Arc Welding for Wire and Arc Additive Manufacturing. In: Reisgen, U., Drummer, D., Marschall, H. (eds) Enhanced Material, Parts Optimization and Process Intensification. EMPOrIA 2020. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-70332-5_15

Download citation

DOI: https://doi.org/10.1007/978-3-030-70332-5_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-70331-8

Online ISBN: 978-3-030-70332-5

eBook Packages: EngineeringEngineering (R0)