Abstract

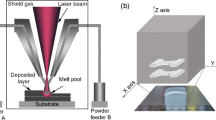

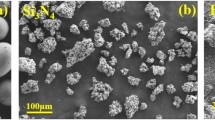

The feasibility of using laser direct energy deposition (DED) additive manufacturing (AM) to synthesize a commercial, aluminum-manganese alloy of the 3000 series was evaluated by comparing the microstructures of AM and direct-chill (DC) cast alloys. The purpose of this work was to establish a baseline for accelerating Al alloy discovery using combinatorial materials synthesis. Feedstock alloy powder was prepared by mixing pure metal element or binary alloy powders via ball-milling and fabricating bulk samples using laser DED AM. Compositional accuracy of both powder feedstock and laser DED AM samples was controlled within 10% of the target. The effect of homogenization on the evolution of second-phase particles as a function of temperature and time was found to be similar in both laser DED AM and DC-cast materials.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhao JC (2006) Combinatorial approaches as effective tools in the study of phase diagrams and composition–structure–property relationships. Progress in Materials Science 51(5): 557–631

Adharapurapu RR, Zhu J, Dheeradhada VS, Lipkin DM, Pollock TM (2014) A combinatorial investigation of palladium and platinum additions to β-NiAl overlay coatings. Acta Materialia 77: 379–393

Payne MA, Miller JB, Gellman AJ (2015) High-throughput characterization of early oxidation across AlxFeyNi1−x−y composition space. Corrosion Science, 91: 46–57

Knoll H, Ocylok S, Weisheit A, Springer H, Jägle E, Raabe D (2017). Combinatorial alloy design by laser additive manufacturing. Steel Research International 88(8): 1600416

Tsai P, Flores KM (2016) High-throughput discovery and characterization of multicomponent bulk metallic glass alloys. Acta Materialia 120: 426–434

Li M, Gazquez J, Borisevich A, Mishra R, Flores KM (2018) Evaluation of microstructure and mechanical property variations in AlxCoCrFeNi high entropy alloys produced by a high-throughput laser deposition method. Intermetallics 95: 110–118

DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Beese AM, Wilsonheid A, De A, Zhang W (2018) Additive manufacturing of metallic components–process, structure and properties. Progress in Materials Science 92: 112–224

Zheng B, Zhou Y, Smugeresky JE, Schoenung JM, Lavernia EJ (2008) Thermal behavior and microstructural evolution during laser deposition with laser-engineered net shaping: Part I. Numerical calculations. Metallurgical and Materials Transactions A 39(9): 2228–2236

Frazier WE (2014) Metal additive manufacturing: a review. Journal of Materials Engineering and Performance 23(6): 1917–1928

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Materialia 117: 371–392

Rosenthal I, Stern A, Frage N (2014) Microstructure and mechanical properties of AlSi10Mg parts produced by the laser beam additive manufacturing (AM) technology. Metallography, Microstructure, and Analysis 3(6): 448–453

Espana FA, Balla VK, Bandyopadhyay (2011) A Laser processing of bulk Al–12Si alloy: influence of microstructure on thermal properties. Philosophical Magazine 91(4): 574–588

Uddin SZ, Murr LE, Terrazas CA, Morton P, Roberson DA, Wicker RB (2018) Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Additive Manufacturing 22: 405–415

Louvis E, Fox P, Sutcliffe CJ (2011) Selective laser melting of aluminum components. Journal of Materials Processing Technology 211(2): 275–284

Svetlizky D, Zheng B, Buta T, Zhou Y, Golan O, Breiman U, Haj-Ali R, Schoenung JM, Lavernia EJ, Eliaz N (2020) Directed energy deposition of Al 5xxx alloy using Laser Engineered Net Shaping (LENS®). Materials and Design: 108763

Ramesh N (2018) Structure-Process-Property Relationships for LENS® and SLM Processed AlSi10Mg Alloys and the Effect of Heat Treatment, MSc thesis, University of California, Irvine

Aboulkhair NT, Simonelli M, Parry L, Ashcroft I, Tuck C, Hague R (2019) 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Progress in Materials Science 106: 100578

Alexander DTL, Greer AL (2002) Solid-state intermetallic phase transformations in 3XXX aluminum alloys. Acta Materialia 50(10): 2571–2583

Westerman EJ, Morris JG, Merchant HD, Morris PL (1993) Aluminum Alloys for Packaging, TMS, Warrendale, PA, p 1–16

Huang HW, Ou BL (2009) Evolution of precipitation during different homogenization treatments in a 3003 aluminum alloy. Materials and Design 30(7): 2685–2692

Alexander DTL, Greer AL (2005) Particle break-up during heat treatment of 3000 series aluminum alloys. Materials Science and Technology 21(8): 955–960

Liu WC, Radhakrishnan B (2010) Recrystallization behavior of a supersaturated Al–Mn alloy. Materials Letters 64(16): 1829–1832

Andrianov AV, Kandalova EG, Aryshensky EV, Grechnikova AF (2016) Influence of 3104 alloy microstructure on sheet performance in ironing aluminum beverage cans. Key Engineering Materials 684: 398–405

Alexander DTL, Greer AL (2004) Nucleation of the Al6 (Fe, Mn) to α-Al–(Fe, Mn)–Si transformation in 3XXX aluminum alloys. II. Transformation in cast aluminum alloys. Philosophical Magazine 84(28): 3071–3083

Alloys, Wrought Aluminum (2015) International Alloy Designations and Chemical Composition Limits for Wrought Aluminum and Wrought Aluminum alloys

Karunakaran R, Ortgies S, Tamayol A, Bobaru F, Sealy MP (2020) Additive manufacturing of magnesium alloys. Bioactive Materials 5(1): 44–54

Ziętala M, Durejko T, Polański M, Kunce I, Płociński T, Zieliński W, Łazińska M, Stępniowski W, Czujko T, Kurzydłowski KJ, Bojar Z (2016) The microstructure, mechanical properties and corrosion resistance of 316 L stainless steel fabricated using laser engineered net shaping. Materials Science and Engineering: A 677: 1–10

Yusuf SM, Chen Y, Boardman R, Yang S, Gao N (2017) Investigation on porosity and microhardness of 316L stainless steel fabricated by selective laser melting. Metals 7(2): 64

Saeidi K, Gao X, Zhong Y, Shen ZJ (2015) Hardened austenite steel with columnar sub-grain structure formed by laser melting. Materials Science and Engineering: A 625: 221–229

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Pan, Q., Kapoor, M., Mileski, S., Carsley, J., Lou, X. (2021). High-Throughput Aluminum Alloy Discovery Using Laser Additive Manufacturing. In: Perander, L. (eds) Light Metals 2021. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-65396-5_21

Download citation

DOI: https://doi.org/10.1007/978-3-030-65396-5_21

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65395-8

Online ISBN: 978-3-030-65396-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)