Abstract

The petrochemical and chemical industries are key enablers of modern societies. Transportation, construction, packaging, food processing, textile, water distribution, medical equipment, and in various other sectors petrochemicals and chemicals are used in making products for improving the quality of our modern living. Among the major five types of feedstocks (as listed below), light olefins are the most important chemical building blocks for the production of the various downstream petrochemicals.

-

Light olefins: ethylene and propylene

-

C4 hydrocarbons: Butanes, butenes, butadiene

-

Aromatics: Benzene, toluene, and xylenes (BTX)

-

Long-chain n-paraffin: Kerosene-derived C9-C17 paraffins

-

Syngas: a mixture of carbon monoxide and hydrogen

Ethylene and propylene are two major light olefins, used as key petrochemical building blocks. Ethylene is used in the production of polyethylene, ethylene chloride, ethylene oxide, etc. These products are used in the construction and packaging, plastic processing, and textile industries, to name just a few examples. Similarly, propylene, the simplest C3 olefin, is used in making a number of useful derivatives such as polypropylene, propylene oxide, acrylonitrile, acrylic acid, cumene, isopropanol, etc. The global propylene demand was around 100 MMTA (million metric tons per annum) in 2015 which is expected to increase at a 3.6% CAGR (compound annual growth rate) to more than 140 MMTA by 2025 due to wider applications of the propylene derivatives in the consumer market. For instance, polypropylene, a key derivative of propylene, is one of the best-selling plastics, extensively used in automobiles and in the manufacturing of packaging films. Acrylonitrile, another propylene derivative, is used in making acrylic fibers and coatings. Similarly, propylene oxide is used extensively for the manufacturing of polyurethanes and other chemicals, acrylic acid and oxo alcohols are employed in PVC plasticizers and coatings-based applications, cumene is used to make epoxy resins and polycarbonate, and isopropyl alcohol is used as solvent, and so on. Not only plastic processing, but also the packaging industry, the furnishing sector as well as the automotive industries are the major consumers of propylene derivatives.

Propylene is a highly activated synthetic molecule and thus it needs to be converted selectively to its derivatives for their cost-effective production. Both propylene production and its selective conversion processes for the production of other chemicals have gone through important improvement in recent times. Thus, it is being felt that it would be interesting to capture the most recent advances in the processes and catalysts associated with propylene production and subsequent conversion of propylene to important C3 chemicals to global readers. The main aim of this book chapter is to bring important aspects of various commercial processes and catalysts involved in the production of propylene and propylene-derived chemicals namely, propylene oxide, acrylonitrile, isopropanol, and acrylic acid. About two-thirds of global propylene is consumed to make polypropylene (PP), which is one of the most versatile plastic materials with good mechanical and chemical properties. However, information related to polypropylene production technologies and associated catalysts is beyond the scope of this chapter.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- 2-EHA:

-

2-Ethyl hexyl acrylate

- 3-HP:

-

3-Hydroxy propionic acid

- ABS:

-

Acrylonitrile-butadiene styrene

- ACN:

-

Acrylonitrile

- atm. :

-

Atmospheres (unit for pressure)

- CAGR:

-

Compound annual growth rate

- CARENA:

-

Catalytic reactors based on new materials

- Conv.:

-

Conversion

- DCC:

-

Deep catalytic cracking

- DIPE:

-

Diisopropyl ether

- DME:

-

Dimethyl ether

- DTP:

-

Dominant technology for propylene production

- EBHP:

-

Ethylbenzene hydroperoxide process

- ECH:

-

Epichlorohydrin

- EPS :

-

Expanded polystyrene foam

- FCC:

-

Fluid catalytic cracking

- GTO:

-

Gas to oil

- HPPO:

-

Hydrogen peroxide-to-propylene-oxide

- IPA:

-

Isopropyl alcohol

- LPG:

-

Liquefied petroleum gas

- MMTPA:

-

Million metric ton per annum

- MTO:

-

Methanol to olefin

- MTP:

-

Methanol to propylene

- OCP:

-

Olefin cracking process

- OCT:

-

Olefin conversion technology

- PDH:

-

Propane dehydrogenation

- PEM:

-

Proton exchange membrane

- PO:

-

Propylene oxide

- POC:

-

Propylene oxide cumene only

- R2P :

-

Residue to propylene

- R2R:

-

Reactor-2-regenerators

- RFCC:

-

Resid fluid catalytic cracking

- SAN:

-

Styrene-acrylonitrile resin

- SAP:

-

Super absorbent polymer

- SOEC:

-

Solid oxide electrolyzer cell

- T :

-

Temperature

- t :

-

Time

- TBHP:

-

Tertiary butyl hydroperoxide

- TSC:

-

Thermal steam cracking

- USY zeolite:

-

Ultra stable Y zeolite

- wt%:

-

Weight percentage

References

Chemicals prices, news and analysis, chemicals market intelligence (2011) http://www.icis.com/v2/chemicals/9076455/propylene/uses.html. Accessed 16 Aug 2011

Corma A, Corresa E, Mathieu Y, Sauvanaud L, Al-Bogami S, Al-Ghrami MS, Bourane A (2017) Crude oil to chemicals: light olefins from crude oil. Cat Sci Technol 7:12–46

Propylene Production and Manufacturing Process I. C. I. S (Independent Commodity Intelligence Services) (2007) https://www.icis.com/explore/resources/news/2007/11/06/9076456/propylene-production-and-manufacturing-process

Bender M (2014) An overview of industrial processes for the production of olefins—C4 hydrocarbons. Chem Bio Eng Rev 1:136–147

Peter E, Richard K (2012) Propene. Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH, Weinheim

Jasper S, El-Halwagi MM (2015) A techno-economic comparison between two methanol-to-propylene processes. Processes 3:684–698

Marcello DF (2017) New catalytic process for production of olefins, oil & gas portal. http://www.oil-gasportal.com/new-catalytic-process-for-production-of-olefins/?print=print

Ante J (2013) Production of olefins—steam cracking of hydrocarbons, petroleum refining and petrochemical processes, natural gas composition, classification, processing. https://pdfs.semanticscholar.org/c70b/5a3ae45c4e1750ffdc3a7ec21ddbfa12a390.pdf?_ga=2.187285610.354597134.1582640836-121132309.1582640836

Werner P (2011) Polyolefins. Applied plastics engineering handbook, processing and materials, plastic design library. Elsevier, Amsterdam, pp 23–48

Leon B (2011) Optimizing FCC operations in a high rare earth cost (market: part I). RefineryOperations.com, vol 2, pp 1–7

Eren C, Nathan L, Theo JS, Jeremy W (2018) Petrochemicals 2030: reinventing the way to win in a changing industry. https://www.mckinsey.com/industries/chemicals/our-insights/petrochemicals-2030-reinventing-the-way-to-win-in-a-changing-industry

Advance in Naphtha Steam Cracking (Process Economics Program Report, 248A) IHS Markit report. https://ihsmarkit.com/pdf/RP248A_toc_173653110917062932.pdf. Accessed Dec 2005

Resid RFCC, Axens solutions. https://www.axens.net/product/process-licensing/10071/r2r.html

Resid to propylene, axenes solutions, website: https://www.axens.net/product/process-licensing/20043/r2p-resid-to-propylene.html

Knight J, Mehlberg R (2011) Maximize propylene from your FCC unit: innovative use of catalyst and operating conditions increases on-purpose olefin production: refining developments. Hydrocarb Process 90:91–95

Degnan TF, Hitnis GKC, Schipper PH (2000) History of ZSM-5 fluid catalytic cracking additive development at mobil. Microporous Mesoporous Mater 35:245–252

Biswas J, Maxwell IE (1990) Recent process- and catalyst-related development in fluid catalytic cracking. Appl Catal 63:1–18

Li Z, Shi W, Wang X, Jiang F (1994) Deep catalytic cracking process for light-olefins production. ACS Symp Ser 571:33–42

Akah A, Al-Ghrami M (2015) Maximizing propylene production via FCC technology. Appl Petrochem Res 5:377–392

Soni D, Rao MR, Saidulu G, Bhattacharyya D, Satheesh VK (2009) Catalytic cracking process enhances production of olefins. Petrol Technol Q Q4:95–100

Aitani A (2006) Propylene production, encyclopedia of chemical processing. Taylor & Francis, New York

Eng CN, Miller RB. Dual riser FCC reactor process with light and mixed light/heavy feeds. US Patent 7491315

Parthasarathi RS, Alabduljabbar SS (2014) HS-FCC high-severity fluidized catalytic cracking: a newcomer to the FCC family. Appl Petrochem Res 4:441–444

Martin BH (2005) Handbook of chemical technology and pollution control, 3rd edn. Academic, New York

Henning G (2013) U.S. shale boom to boost LPG exports, bring down prices, Business News, Reuters. https://www.reuters.com/article/us-energy-lpg/u-s-shale-boom-to-boost-lpg-exports-bring-down-prices-idUSBRE9A30G820131104

Nawaz Z (2015) Light alkane dehydrogenation to light olefin technologies: a comprehensive review. Rev Chem Eng 31:1–24

Caspary KJ, Gehrke H, Heinritz-Adrian M, Schwefer M (2008) In: Ertl G, Knozinger H, Weitkamp J (eds) Handbook of heterogeneous catalysis. Wiley-VHC Verlag GmbH, Weinheim, pp 3206–3229

The Uhde STAR process: oxydehydrogenation of light paraffins to olefins. http://www.thyssenkruppuhde.de/fileadmin/documents/brochures/uhde_brochures_pdf_en_12.df

Sanfilippo D, Miracca I (2005) Oxidation and functionalization: classical and alternative routes and sources. In: Ernst S, Gallei E, Lercher JA, Rossini S, Santacesaria E (eds) Proceedings of the DGMK conference, German Society for Petroleum and Coal Science and Technology (DGMK), Hamburg

GS Engineering/Construction (ed) (2008) Propylene technology by PDH & Metathesis

Lummus-Technology-CB&I-Company (2009) Chicago. CATOFIN dehydrogenation, vol 31, pp 1–2

Hisham A, Maddah A (2018) Comparative study between propane dehydrogenation (PDH) technologies and plants in Saudi Arabia. Am Sci Res J Eng, Technol Sci 45:49–63

CATOFIN dehydrogenation (2013) http://www.com/images/uploads/tech_sheets/CatofinDehyrogenation-12.pdf. Accessed 23 Oct 2013

New clariant CATOFIN propane dehydrogenation catalysts delivers significant savings (2013) http://newsroom.clariant.com/newclariant-catofin-propane-dehydrogenation-catalyst-delivers significant savings/. Accessed 23 Oct 2013

INEOS selects site for €3-billion European petrochemical complex (2019) Oil Gas J. https://www.ogj.com/refiningprocessing/refining/capacities/article/17278908/ineos-selects-site-for-3billion-european-petrochemical-complex. Accessed 15 Jan 2019

Michael M, Jeffrey W (2019) On-purpose propylene production. PTQ Q1: 1–5. https://www.digitalrefining.com/article/1002264,On_purpose_propylene_production.html#.XlVKs6Yh3IU

Metathesis (2005) Kirk-Othmer encyclopedia of chemical technology, vol 20, 5th edn. Wiley, New York, pp 1–29

Mol JC (2004) Industrial application of olefin metathesis. Mol Catal A Chem 213:39–45

Gartside RJ, Greene M. Catalyst and process for the metathesis of ethylene and butene to produce propylene. World Patent 2006052688

Gartside RJ, Greene MI, Kaleem H (2006) Maximize butene-1 yields. Hydrocarbon Process Int Ed 85(57–58):60–61

Gartside RJ, Greene MI, Quincy JJ. Process for producing propylene and hexene from C4 olefin streams. US Patent 6777582B2

Popoff N, Mazoyer E, Pelletier J, Gauvin RM, Taoufik M (2013) Expanding the scope of metathesis: a survey of polyfunctional, single-site supported tungsten systems for hydrocarbon valorization. Chem Soc Rev 42:9035–9054

Banach M (2017) Take the profitable path to olefins using UOP technologies. In: Honeywell oil & gas technologies symposium, Cairo, Egypt

Gogate MR (2019) Methanol-to-olefins process technology: current status and future prospects. Petrol Sci Technol 37:559–565

Koempel H, Liebner W (2007) Lurgi’s methanol to propylene (MTP) report on a successful commercialisation. In: Proceedings of the 8th natural gas conversion symposium, Natal, Brazil, 27–31 May 2007, pp 261–281

Koempel H, Liebner W, Wagner M (2005) Lurgi’s gas to chemicals (GTC): advanced technologies for natural gas monetization. In: Proceedings of the Gastech 2005, Bilbao, Spain, 14–17 March 2005

Hongxing L, Zaiku X, Guoliang Z (2013)The progress of SINOPEC methanol-to-olefins (S-MTO) technology. In: New technologies and alternative feedstocks in petrochemistry and refining, DGMK conference October 9-11 Dresden, Germany

S-MTO methanol to olefins technology (2018) Sinopec. http://oil.vcdcenter.com/wp-content/uploads/2018/12/SMTO.pdf. Accessed Dec 2018

Liu Z, Ye M (2016) DMTO and beyond: DICP’s sustainable innovations in technologies for on-purpose production of light olefins from methanol. In: 16 AIChE, spring meeting, Houston, TX

Hurd D, Park S, Kan J (2014) FITT research: China’s coal-to-olefins industry. AG, Hong Kong: Deutsche Bank. Accessed 2 Jul 2014

Vora B, Marker TL, Nilsen HR (1998) Process for producing light olefins from crude methanol. US Patent 5714662

Funk GA, Myers D, Vora B (2004) A different game plan. Hydro Eng 12:25–28

Lurgi (2008) Methanol to propylene—MTP®. Lurgi AG, Frankfurt am Main, Germany. http://www.lurgi.com/website/fileadmin/user_upload/pdfs/19_Methan-Propylen-E_rev060707.pdf

Olah GA, Goeppert A, Surya Prakash GK (2009) Beyond oil and gas: the methanol economy. Wiley-VCH, Weinheim. ISBN: 9783527324224

Gogate MR (2019) Methanol-to-olefins process technology: current status and future prospects. Petrol Sci Technol 37:1–7. https://doi.org/10.1080/10916466.2018.1555589

Okita A, Honda K (2012) Selective propylene production process using methanol/dimethylether and olefin as raw materials. Petrotech 35:581

Eng CN, Arnold EC, Vora B (1998) Integration of the UOP/HYDRO MTO process into ethylene plants. In: AIChE spring national meeting, session 16, fundamental topics in ethylene production, New Orleans, LA, USA, 8–12 March 1998; Paper 16g

Barger P (2002) Methanol to olefins (MTO) and beyond. Catal Sci Ser 3:239–260

Koempel H, Liebner W (2007) Lurgi’s methanol to propylene (MTP). Report on a successful commercialization. In: Proceedings of the 8th natural gas conversion symposium, Natal, Brazil, 27–31 May 2007, pp 261–281

Farshi A, Shaiyegh F, Burogerdi SH, Dehgan A (2011) FCC process role in propylene demands. Petrol Sci Technol 29:875–885

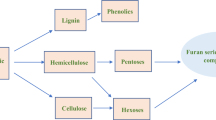

Zacharopoulou V, Lemonidou A (2017) Olefins from biomass intermediates: a review. Catalysts 8:2–19. https://doi.org/10.3390/catal8010002

Manz TA, Yang B (2014) Selective oxidation passing through η3-ozone intermediates: applications to direct propene epoxidation using molecular oxygen oxidant. RSC Adv 4:27755–27774. https://doi.org/10.1039/c4ra03729d

Kawabata T, Koike H, Yamamoto J, Yoshida S (2019) Trends and views in the development of technologies for propylene oxide production. Sumitomo Kagaku (English edition). Report 1, pp 1–9. https://www.sumitomo-chem.co.jp/english/rd/report/files/docs/2019E_1.pdf

IHS markit (2015) Propylene oxide PEP consolidated report CR003

Shang S-Y, Mei L, Fu P (2016) Progress in producing technology of propylene oxide. Advanced materials, technology application. World Scientific, Singapore, pp 62–71. https://doi.org/10.1142/9789813200470_0008

Goyal R, Singh O, Agrawal A, Samanta C, Sarkar B (2020): Advantages and limitations of catalytic oxidation with hydrogen peroxide: from bulk chemicals to lab scale process, Catalysis Reviews, https://doi.org/10.1080/01614940.2020.1796190

Dittmeyer R, Keim W, Kreysa G, Oberholz A (eds) (2005) Winnacker-Küchler: Chemische Technik, 5th edn. Wiley-VCH, Weinheim

Japan External Trade Organization (2018) Chuugoku ni okeru Kankyou Kisei to Shijou Kibo no Saishin Doukou Chousa 2018-nen 1-gatsu. (Survey on Latest Trends in Environmental Regulations and Market Scale in China, January 2018). https://www5.jetro.go.jp/newsletter/shanghai/2018/180126/doukou.pdf

Pell M, Korchak EI (1969) Epoxidation using ethylbenzene hydroperoxide with alkali or adsorbent treatment recycle ethylbenzene. US Patent 3439001

Dubner WS, Cochran RN (1993) Propylene oxide-styrene monomer process. US Patent 5210354

Van Der Sluis JJ (2003) Process for the preparation of styrene and propylene oxide. US Patent 6504038

Oyama ST (2011) Mechanisms in homogeneous and heterogeneous epoxidation catalysis. Elsevier, Amsterdam

Cavani F, Teles JH (2009) Sustainability in Catalytic Oxidation: An Alternative Approach or a Structural Evolution? ChemSusChem, 2 (6), 508–534. https://doi.org/10.1002/cssc.200900020

Hibi T, Iwanaga K, Ito S, Koike H, Oku N (2009) Development of a new Acetophenone hydrogenation process for propylene oxide production. Sumitomo Kagaku, II, Osaka, pp 1–7

Ghanta M, Fahey DR, Busch DH, Subramaniam B (2013) Comparative economic and environmental assessments of H2O2-based and tertiary butyl hydroperoxide-based propylene oxide technologies. ACS Sust Chem Eng 1:268–277. https://doi.org/10.1021/sc300121j

Kollar J (1967) Epoxidation process. US Patent 3351635

Marquis ET, Keating KP, Knifton JF, Smith WA, Sanderson JR, Lustri J (1990) Epoxidation of olefins in a polar medium. US Patent 4891437

Weissermel K, Arpe H-J (2004) Industrial organic chemistry, 5th ed, translated by T. Mukaiyama, Tokyo Kagaku Dozin, p 289

https://www.sumitomo-chem.co.jp/english/news/detail/20190819e.html

https://www.sumitomo-chem.co.jp/english/rd/report/files/docs/20060100_ely.pdf

Schmidt F, Bernhard M, Morell H, Pascaly M, Oggi C (2014) Chem Today 32:31–35

Russo V, Tesser R, Santacesaria E, Di Serio M (2013) Chemical and technical aspects of propene oxide production via hydrogen peroxide (HPPO process). Ind Eng Chem Res 52:1168–1178. https://doi.org/10.1021/ie3023862

Lin M, Xia C, Zhu B, Li H, Shu X (2016) Green and efficient epoxidation of propylene with hydrogen peroxide (HPPO process) catalyzed by hollow TS-1 zeolite: a 1.0 kt/a pilot-scale study. Chem Eng J 295:370–375. https://doi.org/10.1016/j.cej.2016.02.072

http://www.chemicals-technology.com/projects/basf-hppo/. Accessed Jan 2013

http://www.knak.jp/big/evonik-hppo.htm. Accessed Jan 2013

Grosch GH, Mller U, Walch A, Rieber N, Fischer M, Quaiser S, Harder W, Eller K, Bassler P, Wenzel A, Kaibel G, Stammer A, Henkelmann J, Battcher A, Teles JH, Schulz M, Treiber G (2003) Method for oxidizing an organic compound containing at least one C-C double bond. US Patent 6518441

Yap N, Andres RP, Delgass WN (2004) Reactivity and stability of Au in and on TS-1 for epoxidation of propylene with H2 and O2. J Catal 226:156

Nijhuis TA, Huizinga BJ, Makkee M, Moulijn JA (1999) Direct epoxidation of propene using gold dispersed on TS-1 and other titanium-containing supports. Ind Eng Chem Res 38:884

Zheng X, Zhang Q, Guo Y, Zhan W, Guo Y, Wang Y, Lu G (2012) Epoxidation of propylene by molecular oxygen over supported Ag−Cu bimetallic catalysts with low Ag loading. J Mol Catal A Chem 357:106–111

Tatsumi T, Nakamura M, Yuasa K, Tominaga H (1991) Shape selectivity as a function of pore size in epoxidation of alkenes with supported titanium catalysts. Catal Lett 10:259–262

Perego C, Carati A, Ingallina P, Mantegaza MA, Bellussi G (2001) Production of titanium containing molecular sieves and their application in catalysis. Appl Catal A Gen 221:63–72

Short PL (2009) BASF, Dow Open. Novel propylene oxide plant. Chem Eng News 87:21

Khatib SJ, Oyama ST (2015) Direct oxidation of propylene to propylene oxide with molecular oxygen: a review. Catal Rev 57:306–344. https://doi.org/10.1080/01614940.2015.1041849

Vaughan O, Kyriakou G, Macleod N, Tikhov M, Lambert R (2005) Copper as a selective catalyst for the epoxidation of propene. J Catal 236:401–404. https://doi.org/10.1016/j.jcat.2005.10.019

Ghosh S, Acharyya SS, Tiwari R, Sarkar B, Singha RK, Pendem C, Bal R (2014) Selective oxidation of propylene to propylene oxide over silver-supported tungsten oxide nanostructure with molecular oxygen. ACS Catal 4:2169–2174. https://doi.org/10.1021/cs5004454

Kalavachev YK, Hayashi T, Tshbota S, Haruta M (1997) 3rd world congress on oxidation catalysis. Elsevier, Amsterdam

Haruta M (1997) Size- and support-dependency in the catalysis of gold. Catal Today 36:153

Nijhuis TA, Visser T, Weckhuysen BM (2005) Mechanistic study into the direct epoxidation of propene over gold/titania catalysts. J Phys Chem B 109:19309

Nijhuis TA, Chen J, Kriescher SMA, Schouten JC (2010) The direct epoxidation of propene in the explosive regime in a microreactor: a study into the reaction kinetics. Ind Eng Chem Res 49:10479

Chen J, Halin SJA, Schouten JC, Nijhuis TA (2011) Kinetic study of propylene epoxidation with H2 and O2 over Au/Ti−SiO2 in the explosive regime. Faraday Discuss 152:321

Nexant markets and profitability (2018) Market analytics: acrylonitrile. https://www.nexanteca.com/reports/market-analytics-acrylonitrile-2018

The SOHIO acrylonitrile process (2007) Americian Chemical Society. Accessed 14 Nov 2007

Grasselli RK (2011) In: Hess C, Schlögl R (eds) Ammoxidation of propylene and propane to acrylonitrile nanostructured catalysts: selective oxidations. Royal Society of Chemistry, London

Brazdil JF (2012) Acrylonitrile. Ullmann’s encyclopedia of industrial chemistry. Wiley, Hoboken. https://doi.org/10.1002/14356007.a01_177.pub3

Grasselli RK, Ferruccion T (2016) Acrylonitrile from biomass: still far from being a sustainable process. Top Catal 59:1651–1658

Bastião DS (2019) Study of the eco-efficiency of acrylonitrile production processes. http://www.revistasg.uff.br/index.php/sg/article/view/1455/html_1

Grasselli RK (2002) Fundamental principles of selective heterogeneous oxidation in catalysis. Top Catal 21:79–88

Grasselli RK (1999) Advances and future trends in selective oxidation and ammoxidation catalysis. Catal Today 14:49

Callahan JL, Milberg EC (1966) Process for preparing olefinically, unsaturated nitriles. US Patent 3230246

Grasselli RK (1997) Handbook of heterogeneous catalysis. In: Ertl G, Knoezinger H, Weitkamp J (eds) 4.6.6. Ammoxidation. Wiley-VCH, Weinheim, p 2302

Grasselli RK (1983) In: Bonnelle JP, Delmon B, Derouane EG (eds) Surface properties and catalysis by non-metals. D. Riedel, Dordrecht, pp 273–289

Kurt S, Wilhelm V, Joachim K, Rolf S, Gunter S. Process for preparing unsaturated nitriles. US Patent No. 3226422

Grasselli RK, Hardman HF (1972) Process for the manufacture of isoprene from isoamylenes and methyl butanols and catalyst therefore. US Patent 3642930

Grasselli RK, Miller AF, Hardman HF. Process for the manufacture of acrylonitrile and methacrylonitrile. US Patent 4503001

Grasselli RK, Suresh DD, Hardman HF. Production of unsaturated nitriles. US Patent 4139552

Suresh DD, Maria S, Michael F, Seely J. Catalyst for the manufacture of acrylonitrile and methacrylonitrile. US Patent 5212137

Caporali G, Ferlazzo N, Giordano N. Process for the continuous production of olefinically unsaturated nitriles. US Patent 3691224

Bart JCJ, Giordano N (1980) Structure and activity of tellurium-molybdenum oxide acrylonitrile catalysts. J Catal 64:356–370

Bart JCJ, Giordano N (1984) Structure of the cerium-molybdenum-tellurium oxide acrylonitrile catalyst. Ind Eng Chem Prod Res Dev 23:56

Grasselli RK, Callahan JL (1969) Structure-catalytic efficiency relationships in U Sb oxide acrylonitrile synthesis catalysts. J catal 14:93–103

Grasselli RK, Suresh DD, Knox K (1970) Crystalline structures of USb3O10 and USbO5 in acrylonitrile catalysts. J Catal 18:356–358

Grasselli RK, Suresh DD, Knox K (1972) Aspects of structure and activity in U Sb oxide acrylonitrile catalysts. J Catal 25:273–291

Callahan J L, Berthold G. Mixed antimony oxide-uranium oxide oxidation catalyst. US Patent 3198750

Sasaki Y, Utsumi H, Miyaki K. Iron antimony-containing metal oxide catalyst composition and process for producing the same. Jap Patent 3142549

Sasaki Y, Nakamura T, Nakamura Y, Moriya K, Utsumi H, Saito S (1983) Process for production of acrylonitrile. US Patent 4370279

Krieger J (1996) Propane route to acrylonitrile holds promise of savings. Chem Eng News 74(39):18–19

Ushikubo T, Oshima K, Kayou A, Hatano M (1997) Ammoxidation of propane over Mo-V-Nb-Te mixed oxide catalysts. Spillover and migration of surface species on catalysts. In: Proceedings of the 4th international conference on spillover, pp 473–480. https://doi.org/10.1016/s0167-2991(97)80871-3

Hinago H, Komada S (2000) Ammoxidation catalyst for use in producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation. US Patent 6063728

Ushikubo T (2000) Recent topics of research and development of catalysis by niobium and tantalum oxides. Catal Today 57:331–338

Adams RD, Elpitiya G, Khivantsev K, Blom D, Alexeev OS, Amiridis MD (2015) Ammoxidation of propane to acrylonitrile over silica-supported Fe-bi nanocatalyst. App Catal A: Gen 501:10–16

Karp et al (2017) Science 358:1307–1310

Nexant (2010) Acrylic acid, process evaluation/research planning (PERP) 08/09. www.chemsys.com

IHS Markit report (2016) CEH Superabsorbent polymers report. https://ihsmarkit.com/Info/0319/acrylates-sap-client-webinar.html

Grand view Research Inc (2017) grandviewresearchinc.weebly.com/blog/acrylic-acid-market-is-expected-to-show-a-momentous-role-in-demand-development

Tullo AH (2013) Hunting for biobased acrylic acid. Chem Eng News 19:18–19

Nova Institute for ecology and Innovation (2015) Bio-based building blocks and polymers in the world. http://www.bio-based.eu/market_study/media/files/15-05-13_Bio-based_Polymers_and_Building_Blocks_in_the_World-nova_Booklet.pdf

World of Chemical (2014) BASF, Sinopec JV to build acrylic acid. SAP plant in Nanjing, China. https://www.chemicals-technology.com/projects/basf/

Nojiri N, Sakai Y, Watanabe Y (1995) Two catalytic technologies of much influence on progress in chemical process development in Japan. Catal Rev 37:145–178. https://doi.org/10.1080/01614949508007093

Ohara T, Sato T, Shimizu N, Schwind GPH, Weiberg O, Marten K, Greim H (2003) Acrylic acid and derivatives. Ullmann’s encyclopedia of industrial chemistry. Wiley-VCH, Weinheim, pp 1–19

https://www.engineering-airliquide.com/acrylic-acid-lurgi-nippon-kayaku-technology

Lin MM (2001) Selective oxidation of propane to acrylic acid with molecular oxygen. Appl Catal A Gen 207:1–16

Callahan JL, Foreman B W (1960) Process for the oxidation of olefins. US Patent 2941007

Sennerwalt K, Gehrmann K, Vogt W, Schafer S (1960) Process for the manufacture of unsaturated aldehydes or ketones. US Patent 3171859

Takenaka S, Yamaguchi G (1969) Acrolein by propylene oxidation. JP 44006245

Takenaka S, Kido Y, Shimabara T, Ogawa M ( 1971) Catalysts for the oxidation of propylene to acrolein. DE 2038749

Nagai I, Yanagisawa I, Ninomiya M, Oohara T (1976) Oxidation of propylene. JP 51004113

Takata M, Aoki R, Sato T (1983) Catalyst for oxidation of propylene. DE 3300044

Shiraishi T, Kishiwada S, Shimizu S, Hommaru S, Atsumi A, Ichihashi H, Nagaoka Y (1973) JP Patent 4849710A

Koshikawa T (1974) Acrolein and acrylic acid from propylene. JP 49030308

Watanabe Y, Sugihara T, Takagi K, Imanari M, Nojiri N (1972) JP Patent 4741329B

Umemura Y, Oodan K, Suzuki K, Bandou Y, Hisayuki T. (1980) Acrolein. JP Patent 55157529

Izawa S, Ono I, Iikuni T (1965) JP Patent 411775B

Yanagida M , Kitahara M (1969) JP Patent 4426287B

Suzuki S, Itoh H, Inoue H (1970) JP Patent 4516090B

Takenaka S, Yamaguchi K (1969) JP Patent 4412129B

Ogawa M (1987) JP Patent 6234742B

Allen GC (1969) Oxidation of unsaturated aldehydes to the corresponding acids. US Patent 3644509

Krabetz R, Engelbach H (1970) Production of acrylic acid by oxidation of acrolein. US Patent 3845120

Wada M, Ninomiya M, Yanagisawa I, Ohara T (1978). JP Patent 536127B

Dolhyj SR, Milberger EC (1975) Ger Patent 2448804

Shiraishi T, Ichihashi H, Kikuzono Y, Nagaoka Y (1982) JP Patent 57298B

Kadowaki K, Koshikawa T (1974) JP Patent 44169B

Kurata N, Matsumoto T, Ohara T, Oda K (1967) JP Patent 42-9805B

Nagai I, Yanagisawa I, Ninomiya M, Ohara T (1983) JP Patent 5817172B

Takenaka S, Yamaguchi G (1970) JP Patent 454970A

Takayama Y, Nakayama Y, Asao S, Tokumichi Y, Mizukami S (1967) JP Patent 4212243

Kita T, Ishii H (1972) JP Patent 476606B

Croci M, Cavaterra E (1969) Process for the preparation of unsaturated acids. US Patent 3736355

Krabetz R, Engelbach H (1967) Production of acrylic acid. US Patent 3527797

Komuro I, Kadowaki K, Koshikawa T (1972) JP Patent 4722813B

Ukihashi H, Oda Y, Kojima G (1971) JP Patent 469134B

Ono I, Iikuni T, Mizoguchi J (1972). JP Patent 4714204B

Eden JS (1967, 1969) Catalytic process for preparing unsaturated acids and aldehydes. US Patent 3520923 (1967) and US Patent 3585152

Mizuno N, Tateishi M, Iwamoto M (1995) Pronounced catalytic activity of Fe0.08Cs2.5H1.26PVMo11O40 for direct oxidation of propane into acrylic acid. Appl Catal A Gen 128:L165–L170

Luo L, Labinger J, Davis M (2000) Catalysis and surface science. In: Poster, 219th ACS meeting, March 2000. The catalyst was provided by BP Amoco

Velazco MR, McDonnell W, Smith AWJ (2017) Molybdenum/bismuth based mixed metal oxide catalysts for selective propylene oxidation and zeolite membrane protected palladium/ alumina catalysts for selective carbon monoxide oxidation and application in a process loop using a propane feed. Johnson Matthey Technol Rev 61:5–15

Wang K, Vartuli JC, Mortier WJ, Dakka JM, Lemon RC, Mixed metal oxide catalysts and processes for their preparation and use. US Patent 7910772

Dieterle M, Heilek J, Mueller-Engel KJ. Method for the heterogeneously catalyzed partial direct oxidation of n-propane to acrylic acid. US Patent 7795470

Gaffney AM, Song R. Hydrothermally synthesized Mo-V-M-Nb-X oxide catalysts for the selective oxidation of hydrocarbons. US Patent 7718568

Hancock EG (1973) Propylene and its industrial derivatives. E. Benn, London

Persistent Market Search (2020) Isopropanol market: global industry analysis and forecast 2016–2026. https://www.persistencemarketresearch.com/market-research/isopropanol-market.asp

IHS Markit (2018) Isopropyl alcohol (IPA); chemical economics handbook. https://ihsmarkit.com/products/isopropyl-alcohol-ipa-chemical-economics-handbook.html

Xu Y, Chuang KT, Sanger AR (2002) Design of a process for production of isopropyl alcohol by hydration of propylene in a catalytic distillation column. J Trans IChemE 80(Part A):686–694

Beroe Advantage Procurement (2018) Global market outlook on isopropanol. Isopropanol Market Intelligence. https://www.beroeinc.com/commodity/ipa-market/

Kroschwitz JI (1991) Kirk–Othmer encyclopedia of chemical technology, vol 20, 4th edn. Wiley, New York, pp 216–240

Roy A (2018) The text book of industrial chemistry. Technology & Engineering (Lulu.com). ISBN-13: 978-0359095896

Ester W (1970) Process for production of alcohols by catalytic hydration of olefins. GB Patent 1201181

Neier W, Woellner J (1972) Use cation catalyst for IPA. Hydrocarb Process 51:113–116

Onoue Y, Mitzutani Y, Akiyama S, Izumi Y (1978) Hydration with water. ChemTech 8:432–435

Izumi Y, Kawasaki Y, Tani M (1973) Process for the preparation of alcohols. US Patent 3758615

Lin YP (2012) Asian Chemical profile: isopropanol, ICIS (Independent Commodity Intelligence Service). https://www.icis.com/explore/resources/news/2012/12/16/9624355/asian-chemical-profile-isopropanol/

Kosaka Y, Sinclair KB (1982) Bisphenol A: from phenol and acetone with an ion exchange resin catalyst, Union Carbide Technology, Process Economics Reviews, PEP’82-1. https://ihsmarkit.com/pdf/RW82-1-1_220283110917062932.pdf

Mitsui Chemicals Inc (2011) New facilities to produce acetone-based isopropyl alcohol at Osaka works. https://jp.mitsuichemicals.com/en/release/2011/pdf/110829e.pdf

Ovrebekk H (2008) Novapex to build 40,000 t/year France IPA plant, ICIS (Independent Commodity Intelligence Services) https://www.icis.com/explore/resources/news/2008/07/18/9141257/novapex-to-build-40-000-t-yr-france-ipa-plant/

Hayes KS, Mitchell JW, Niak A, Turcotte MG. Hydrogenation of acetone. US Patent 7041857

Fukuhara H, Matsunaga F, Shibuta Y, Tachi T. Preparation of Isopropanol. US Patent 5081321

Rueter MA. Acetone hydrogenation using a supported ruthenium catalyst. US Patent 5495055

Pompetzki W, Schuler J, Maschmeyer D. Process for the hydrogenation of acetone. US Patent 6930213

Balouch A, Ali Umar A, Shah AA, Mat Salleh M, Oyama M (2013) Efficient heterogeneous catalytic hydrogenation of acetone to isopropanol on semihollow and porous palladium nanocatalyst. ACS Appl Mater Interfaces 5:9843–9849. https://doi.org/10.1021/am403087m

Rahman A (2010) Catalytic hydrogenation of acetone to isopropanol: an environmental benign approach. Chem React Eng Catal 5:113–126

Li C, Sallee AM, Zhang X, Kumar S (2018) Electrochemical hydrogenation of acetone to produce isopropanol using a polymer electrolyte membrane reactor. Energies 11:2691

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Samanta, C., Das, R.K. (2021). C3-Based Petrochemicals: Recent Advances in Processes and Catalysts. In: Pant, K.K., Gupta, S.K., Ahmad, E. (eds) Catalysis for Clean Energy and Environmental Sustainability. Springer, Cham. https://doi.org/10.1007/978-3-030-65021-6_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-65021-6_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65020-9

Online ISBN: 978-3-030-65021-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)