Abstract

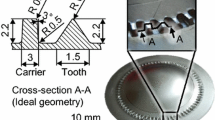

Within the scope of the subproject “Dynamic Process Forces” of the Collaborative Research Centre TCRC 73, a sheet-bulk metal forming (SBMF) process was developed to produce a demonstrator component with internal and external gearing from a sheet metal blank in three production steps. In the first step, a cup is deep-drawn. A hole is shear-cut in the centre of the cup and the cup frame is displaced into a tooth cavity by a compression punch so that the external gearing is formed. In a subsequent second step, an internal gearing is formed by an upsetting punch. A recalibration of the internal gearing takes place in a third process step. In the course of the project, methods for a better control of the material flow and for increasing component quality are investigated in order to extend the limits of sheet-bulk metal forming. These methods include the installation of superimposed oscillation in the main force flow of the forming machine and the use of structured and coated tools, the so-called tailored surfaces.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Blaha, F., Langenecker, B.: Dehnung von Zink-Einkristallen unter Ultraschalleinwirkung. Naturwissenschaften 42(20), 556 (1955)

Osakada, K., Wang, X., Hanami, S.: Precision forging of spline by flashless die forging with axially driven die. Ann. CIRP 46(1), 209–212 (1997)

Liu, Y., Suslov, S., Han, Q., Hua, L., Xu, C.: Comparison between ultrasonic vibration-assisted upsetting and conventional upsetting. Metall. Mater. Trans. A 44(7), 3232–3244 (2013)

Ulmer, J.: Beitrag zur Berechnung der Reibungskraftreduktion beim ultraschallüberlagerten Streifenziehversuch. In: DGM Informationsgesellschaft (Hrsg.) Beiträge zur Umformtechnik-Band 37. Universität Stuttgart, Institut für Umformtechnik-PhD Thesis (2003)

Eaves, A.E., Smith, A.W., Waterhouse, W.J., Sansome, D.H.: Review of the application of ultrasonic vibrations to deforming metals. Ultrasonics 13(4), 162–170 (1975)

Koch, S., Vucetic, M., Hübner, S., Bouguecha, A., Behrens, B.-A.: Superimposed oscillating and non-oscillating ring compression tests for sheet-bulk metal forming technology. Adv. Mater. Res. Appl. Mech. Mater. 794, 89–96 (2015)

Behrens, B.-A., Bouguecha, A., Vucetic, M., Hübner, S., Rosenbusch, D., Koch, S.: Numerical and experimental investigations of multistage sheet-bulk metal forming process with compound press tools. In: 18th International ESAFORM Conference on Material Forming; Key Engineering Materials, vol. 651–653, pp. 1153–1158 (2015)

Müller, P., Rosenbusch, D., Wehmeyer, J., Hübner, S., Behrens, B.: Investigations of forming force, friction values and surface qualities in ring compression tests using oscillating tools. In: Production at the Leading Edge of Technology, Proceedings of the 9th Congress of the German Academic Association for Production Technology (WGP), Hamburg, 30 September–2 October, pp. 73–81 (2019)

Löffler, M., Andreas, K., Engel, U., Schulte, R., Groebel, D., Krebs, E., Freiburg, D., Biermann, D., Stangier, D., Tillmann, W., Weikert, T., Wartzack, S., Tremmel, S., Lucas, H., Denkena, B., Merklein, M.: Tribological measures for controlling material flow in sheet-bulk metal forming. Prod. Eng. 10, 459–470 (2016)

Male, A.T., Cockcroft, M.G.: A method for determination of the coefficient of friction of metals under conditions of, bulk plastic deformation. J. Inst. Met. 93, 38 (1964)

Behrens, B.-A., Meijer, A., Stangier, D., Hübner, S., Biermann, D., Tillmann, W., Rosenbusch, D., Müller, P.: Static and oscillation superimposed ring compression tests with structured and coated tools for Sheet-Bulk Metal Forming. J. Manuf. Processes 55, 78–86 (2020)

Behrens, B.-A., Hübner, S., Vucetic, M.: Influence of superimposed oscillation on sheet-bulk metal forming. In: Key Engineering Materials, ESAFORM 2013, vol. 554–557, pp. 1484–1489 (2013)

Ersoy, K., Labermeyer, M.: Werkzeugverschleiß sicher vorhersagen; Modulare Werkzeugsysteme; Blech InForm; TU München; Garching: Carl Hanser Verlag (2007)

Behrens, B.-A., Koch, S. Vucetic, M.: Superimposed oscillating and non-oscillating ring compression tests for sheet-bulk metal forming technology. In: Applied Mechanics and Materials, vol. 794, pp. 89–96. Trans Tech Publications, Switzerland (2015)

Behrens, B.-A., Rosenbusch, D., Bouguecha, A., et al.: Advanced finite element analysis of die wear in sheet-bulk metal forming processes. In: ESAFORM 2016, Nantes, France (2016)

Iksoo, K.: Einfluß des Spannungszustandes während eines hydraulischen Tiefungsversuchs auf das Umformverhalten von Blechwerkstoffen. In: Berichte aus dem Institut für Eisenhüttenkunde (9) (2002)

Guzmán, C.-F.: About the Lode angle influence in ductile fracture. Technical Report, October 2013

Basaran, M.: Stress state dependent damage modeling with a focus on the lode angle influence. In: Berichte aus dem Maschinenbau (2011)

Behrens, B.-A., Vucetic, M., Peshekhodov, I.: Method for characterisation of fracture behaviour of high-strength sheet steels in a wide range of stress states with the help of uniaxial tensile testing machines. In: Forschungvereinigung Stahlanwendung, pp. 1–62 (2013)

Besson, J.: Continuum models of ductile fracture: a review. Int. J. Damage Mech. 19, 3–52 (2010)

Isik, K., Gerstein, G., Schneider, T., Schulte, R., Rosenbusch, D., Clausmeyer, T., Nürnberger, F., Vucetic, M., Koch, S., Hübner, S., Behrens, B.-A., Tekkaya, A.E., Merklein, M.: Investigations of ductile damage during the process chains of toothed functional components manufactured by sheet-bulk metal forming. Prod. Eng. Res. Dev. 10(1), 5–15 (2016). https://doi.org/10.1007/s11740-016-0656-9

Jia, Y., Bai, Y.: Ductile fracture prediction for metal sheets using all-strain-based anisotropic eMMC model. Int. J. Mech. Sci. 115–116, 516–531 (2016)

Bai, Y., Wierzbicki, T.: Application of extended Mohr–Coulomb criterion to ductile fracture. Int. J. Fract. 161, 1–20 (2010)

Bai, Y., Wierzbicki, T.: A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 24, 1071–1096 (2008)

Mohr, D., Henn, S.: Calibration of stress-triaxiality dependent crack formation criteria: a new hybrid experimental-numerical method. Exp. Mech. 47, 805–820 (2007)

Bai, Y.: Effect of loading history in necking and fracture. Ph. D. Thesis (2008)

Peshekhodov, I.: Experimental-numerical method for characterising the fracture behaviour of high-strength steel sheets. Ph. D. Thesis. Berichte aus dem IFUM (2018)

Acknowledgment

This study was supported by the German Research Foundation (DFG) within the scope of the Transregional Collaborative Research Centre for sheet-bulk metal forming (TCRC 73, grant number 68237143) within the scope of the subproject A7 grant number 116817829.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Behrens, BA., Hübner, S., Wester, H., Rosenbusch, D., Müller, P. (2021). Dynamic Process Forces. In: Merklein, M., Tekkaya, A.E., Behrens, BA. (eds) Sheet Bulk Metal Forming . TCRC73 2020. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-61902-2_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-61902-2_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-61901-5

Online ISBN: 978-3-030-61902-2

eBook Packages: EngineeringEngineering (R0)