Abstract

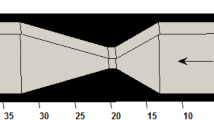

Venturi-type devices can vary from minor adjustments in their geometry to more complex engineering adaptations, depending on their industrial application: automotive, food, agricultural, oil, among others. Thus, their study still becomes necessary nowadays. And the computational modeling aggregates as an important additional tool for investigation and determination of flow variables as the pressure recovery, that affect stability and performance in the processes that apply the Venturi principle. Therefore, this numerical study aims to analyze the flow pressure recovery in Venturi-type devices. In this analysis, flows turbulent, incompressible, and isothermal were assumed. The governing equations involved are the Reynolds-averaged Navier–Stokes equations. Three types of k–epsilon models were employed to solve the turbulence. One commercial software for computational fluid dynamics, which uses a finite volume method in the discretization of the governing equations, was used to obtain the solutions. The simulations’ results were compared to experimental data for the pressure and showed a satisfactory concordancy, aiming to demonstrate the applicability of the computational model developed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

McDonald AT, Fox RW (1966) An experimental investigation of incompressible flow in conical diffusers. Int J Mech Sci 8(2):125–139. https://doi.org/10.1016/0020-7403(66)90071-3

Fox RW, McDonald AT, Pritchard PJ (2011) Introduction to Fluid Mechanics, 8th edn. John Wiley & Sons Inc., Hoboken

Domingues RB (2006) Injeção de partículas de FCC usando injetores gás–sólido tipo Venturi. Master’s thesis, Faculdade de Engenharia Mecânica, Universidade Estadual de Campinas, Campinas, SP. In Portuguese. http://www.repositorio.unicamp.br/handle/REPOSIP/263320

Giddings D, Azzopardi BJ, Aroussi A, Pickering SJ (2007) Absolute measurement of pneumatically conveyed powder using a single long throat Venturi. Powder Technol 172(3):149–156. https://doi.org/10.1016/j.powtec.2006.10.044

Xu C, Liu B, Jing S (2011) Compact pneumatic pulse-jet pump with Venturi-like reverse flow diverter. Chin J Chem Eng 19(4):626–635. https://doi.org/10.1016/S1004-9541(11)60033-5

Xu C, Liu B (2012) Venturi-type fluidic sampler for liquid-solid mixtures. Particuology 10(3):283–291. https://doi.org/10.1016/j.partic.2011.09.003

Mi T, Yu XM (2012) Dust removal and desulphurization in a novel Venturi scrubber. Chem Eng Process Process Intensif 62:159–167. https://doi.org/10.1016/j.cep.2012.07.010

Baylar A, Aydin MC, Unsal M, Ozkan F (2009) Numerical modeling of Venturi flows for determining air injection rates using Fluent v6.2. Math Comput Appl 14(2):97–108. https://doi.org/10.3390/mca14020097

Puentes NAG, Guerra VG, Coury JR, Gonçalves JAS (2012) Droplet dispersion angle measurements on a Pease-Antony Venturi scrubber. Braz J Chem Eng 29(1):99–106. https://doi.org/10.1590/S0104-66322012000100011

Boothby LK, Garred MA, Woods JP (1988) Application of hydraulic jet pump technology on an offshore production facility. In: SPE annual technical conference and exhibition. Society of Petroleum Engineers (SPE), Houston, TX, pp 18236:1–18236:9. Document ID: SPE-18236-MS. https://doi.org/10.2118/18236-MS

Jacobs EG (1989) Artificial lift in the Montrose field, North Sea. SPE Prod Eng 4(3):313–320. https://doi.org/10.2118/15869-PA

Oliveira EF, Botrel TA, Frizzone JA, Paz VPS (1996) Hydraulic analysis of hydro-ejectors. Sci Agric 53(2–3):241–248. https://doi.org/10.1590/S0103-90161996000200009

Chen S, Yang D, Zhang Q, Wang J (2009) An integrated sand cleanout system by employing jet pumps. J Can Pet Technol 48(5):17–23. https://doi.org/10.2118/09-05-17-TN

Xu S, Luo W, Zeng F, Gu Y (2011) Application of deep hydraulic jet perforating to enhance oil production in thin reservoir with bottom water. In: SPE Asia Pacific Oil and Gas conference and exhibition. Society of Petroleum Engineers (SPE), Jakarta, pp 145978:1–145978:12. Document ID: SPE-145978-MS. https://doi.org/10.2118/145978-MS

Granados J, Mancilla SF (2012) Analysis of hydraulic-jet lift system application on wells in the North Region Assets, AIPRA and AIATG (case study). In: SPE Annual Technical Conference and Exhibition, Society of Petroleum Engineers (SPE), San Antonio, TX, pp 160090:1–160090:8. Document ID: SPE-160090-MS. https://doi.org/10.2118/160090-MS

Ishimoto J, Kamijo K (2003) Numerical simulation of cavitating flow of liquid helium in Venturi channel. Cryogenics 43(1):9–17. https://doi.org/10.1016/S0011-2275(02)00149-2

Ghassemi H, Fasih HF (2011) Application of small size cavitating Venturi as flow controller and flow meter. Flow Meas Instrum 22(5):406–412. https://doi.org/10.1016/j.flowmeasinst.2011.05.001

Cruz-Maya JA, Sánchez-Silva F, Quinto-Diez P (2006) A new correlation to determine the discharge coefficient of a critical Venturi nozzle with turbulent boundary layer. Flow Meas Instrum 17(5):258–266. https://doi.org/10.1016/j.flowmeasinst.2006.06.002

Ahmadvand F, Talaie MR (2010) CFD modeling of droplet dispersion in a Venturi scrubber. Chem Eng J 160(2):423–431. https://doi.org/10.1016/j.cej.2010.03.030

Hollingshead CL, Johnson MC, Barfuss SL, Spall RE (2011) Discharge coefficient performance of Venturi, standard concentric orifice plate, V-cone and wedge flow meters at low Reynolds numbers. J Pet Sci Eng 78(3–4):559–566. https://doi.org/10.1016/j.petrol.2011.08.008

Blocken B, van Hooff T, Aanen L, Bronsema B (2011) Computational analysis of the performance of a Venturi-shaped roof for natural ventilation: Venturi-effect versus wind-blocking effect. Comput Fluids 48(1):202–213. https://doi.org/10.1016/j.compfluid.2011.04.012

He D, Bai B (2012) Numerical investigation of wet gas flow in Venturi meter. Flow Meas Instrum 28:1–6. https://doi.org/10.1016/j.flowmeasinst.2012.07.008

Wang C, Ding H, Zhao Y (2014) Influence of wall roughness on discharge coefficient of sonic nozzles. Flow Meas Instrum 35:55–62. https://doi.org/10.1016/j.flowmeasinst.2013.11.007

Sanghani C, Jayani D (2016) Optimization of Venturimeter geometry for minimum pressure drop using CFD analysis. Recent Trends Fluid Mech 3:31–35

Sharp ZB, Johnson MC, Barfuss SL (2018) Optimizing the ASME Venturi recovery cone angle to minimize head loss. J Hydraul Eng 144(1):04017057:1–04017057:9. https://doi.org/10.1061/(ASCE)HY.1943-7900.0001387

Jing J, Yuan Y, Du S, Yin X, Yin R (2019) A CFD study of wet gas metering over-reading model under high pressure. Flow Meas Instrum 69:101608:1–101608:10. https://doi.org/10.1016/j.flowmeasinst.2019.101608

Tannehill JC, Anderson DA, Pletcher RH (1997) Computational fluid mechanics and heat transfer. Series in computational and physical processes in mechanics and thermal sciences, 2nd edn. Taylor & Francis Group, Washington, DC

Launder BE, Spalding DB (1974) The numerical computation of turbulent flows. Comput Methods Appl Mech Eng 3(2):269–289. https://doi.org/10.1016/0045-7825(74)90029-2

Yakhot V, Orszag SA (1986) Renormalization group analysis of turbulence I. Basic Theory. J Sci Comput 1(1):3–51. https://doi.org/10.1007/BF01061452

Yakhot V, Orszag SA, Thangam S, Gatski TB, Speziale CG (1992) Development of turbulence models for shear flows by a double expansion technique. Phys Fluids A: Fluid Dyn 4(7):1510–1520. https://doi.org/10.1063/1.858424

Shih TH, Liou WW, Shabbir A, Yang Z, Zhu J (1995) A new \(k\)-\(\epsilon \) eddy viscosity model for high reynolds number turbulent flows. Comput Fluids 24(3):227–238. https://doi.org/10.1016/0045-7930(94)00032-T

Sarkar S, Lakshmanan B (1991) Application of a Reynolds stress turbulence model to the compressible shear layer. AIAA J 29(5):743–749. https://doi.org/10.2514/3.10649

Henkes RAWM, Van Der Vlugt FF, Hoogendoorn CJ (1991) Natural-convection flow in a square cavity calculated with low-Reynolds-number turbulence models. Int J Heat Mass Transf 34(2):377–388. https://doi.org/10.1016/0017-9310(91)90258-G

EDIBON (2012) Practical exercises manual of the AFT unit. EDIBON international–technical teaching equipment, Madrid, 1st edn. Manual of the experimental unit for study and measurement of head loss in pipes and accessories

Patankar SV (1980) Numerical heat transfer and fluid flow. Series in computational methods in mechanics and thermal sciences, 1st edn. Hemisphere Publ, Co., New York, NY

ANSYS (2017) ANSYS Fluent Tutorial Guide. ANSYS Inc, Canonsburg, PA. Release 18

Acknowledgements

The authors thank the Federal University of Technology–Paraná for the resources made available.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Caetano, N.M., Lima, L.E.M. (2021). Numerical Assessment of the Pressure Recovery of the Turbulent Flow in a Venturi-Type Device. In: Balthazar, J.M. (eds) Vibration Engineering and Technology of Machinery. Mechanisms and Machine Science, vol 95. Springer, Cham. https://doi.org/10.1007/978-3-030-60694-7_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-60694-7_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-60693-0

Online ISBN: 978-3-030-60694-7

eBook Packages: EngineeringEngineering (R0)