Abstract

Use of solar thermal devices has proved a viable option for power generation in many countries that have abundant solar radiation throughout the year. Power Tower and Parabolic Trough collectors are the most common and commercially proven technologies in such solar thermal power plants. This paper presents the design and simulation of 1 MWe solar thermal power plant in which the steam is generated by Australian Nation University’s (ANU) 520 m2 solar parabolic dish concentrators. The plant also powers a vapour absorption-chilling unit that uses steam extracted from the turbine to produce a cooling effect. This paper discusses the design of the power cycle, and through the simulation, estimates the annual power generation from the power block and tonnes of refrigeration produced by vapour absorption chiller. Apart from the design of the power cycle, the layout of dishes is also designed for maximum steam generation from the solar field. The waste heat from the vapour absorption system may be used for low-grade heating applications.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

5.1 Introduction

Energy is the major requirement in the development of any country. At the global level, the demand for primary energy consumption is met mainly by fossil fuels, which are the major contributor to global warming. In order to mitigate this, renewable energy sources which are inexhaustible is the key solution. Amongst various renewable energy sources solar and wind have the major stake in world energy supply through renewables. As per ETP, 2015, these two sources have the potential to reduce 22% of annual emissions in 2050. In solar energy especially the solar thermal in general and concentrating solar power (CSP) in particular has the potential to provide 7 and 25% of the world electricity by 2030 and 2050 respectively (Ummadisingu and Soni 2011; Sunil 2017; Gakkhar et al. 2016; Soni and Gakkhar 2014; Sunil and Soni 2019).

India with a strong economic growth rate is one of the fastest developing economies in the world. In order to sustain and accelerate this growth rate further, the demand for energy will grow simultaneously. The supply of this required energy should be secured, sustainable, affordable and environmental friendly also. For this solar energy plays a very important role as India is blessed with 250–300 clear and sunny days. Most part of the country receiving 4–7 kWh/m2 of solar radiation incident over India’s land area, which is equal to 5 trillion MWh per year energy (Sunil 2017; JNNSM 2009; Energy Technology Perspectives 2015).

5.1.1 Solar Power Generation

Solar energy is utilised to generate power in two different manners. First is the use of Photovoltaic effect of light-absorbing materials, for example, silicone, to directly generate electricity. The second way to utilise solar energy is to use the heat aspect of the sun’s radiation as a thermal source of energy. In conventional thermal power plants, coal is used to generate steam. Instead of burning coal, solar thermal energy can be used to generate steam, reducing the carbon emissions from the power plant drastically.

Major components of a standard thermal power plant are turbine, condenser, pumps and boiler. In solar thermal power plants, the steam generation is done by solar concentrators instead of boilers (Nayak et al. 2015). Auxiliary boilers are usually present to provide backup thermal power for non-sunshine hours.

5.1.2 Solar Space Cooling

Producing cooling effect from solar thermal energy is possible through vapour absorption refrigeration system (VARs). The VARs in common use are (1) aqua-ammonia system with ammonia as refrigerant and water as absorbent, (2) water - lithium bromide (Li Br) system where LiBr is an absorbent and water as a refrigerant. Major components of such units include components like absorber, small pump, generator, condenser, expansion device and evaporator. In VARs, the refrigerant gets absorbed in the absorber, the strong solution is then pumped to generator raising its pressure. In generator, the heat is supplied, which may through solar energy or any waste heat available. Due to this heat addition, the solution of absorbent and refrigerant is heated. As it is heated over the boiling point of the refrigerant, the refrigerant gets separated from the absorbent. The refrigerant vapours are then condensed in the condenser and the condensate is then throttled to the evaporator pressure and then gets evaporated in the evaporator producing cooling effect. The refrigerant produces a cooling effect in the evaporator and releases the heat to the atmosphere via the condenser. Le Lostec et al. (2013) have done a numerical simulation of aqua ammonia vapour absorption chiller and validated the results with the experimental data.

5.1.3 Cogeneration

Cogeneration, also called Combined Heat and Power is a systematic way to draw some minor fraction of steam from the turbine for an application that may require heat (Sahoo 2018). In this paper, the steam required by the VARs chiller is taken out of the turbine at an intermediate pressure.

Colonna and Gabrielli (2003) analysed an industrial tri-generation system producing electrical power, heat and cooling. They analysed VARs with waste heat recovery from internal combustion engines in the form of pressurized hot water, which is then supplied to VARs for the cases of Italy and Netherlands. Behnam et al. (2018) analysed a small-scale tri-generation system with a geothermal energy source to produce power using organic Rankine cycle-based power plant, LiBr based VARs and heat for desalination.

5.2 Design of Power Plant

5.2.1 Site Selection

The site under consideration is Muni Seva Ashram at Goraj, Vadodara. The site is adjacent to the existing solar field of 100 Scheffler dishes. Dev river runs nearby providing water to the ashram. Water from the same river is considered to be used for running the power plant and its cogeneration elements after treatment. The utility building of the ashram which houses a boiler, backup diesel gen-sets and centralized refrigeration system is also adjacent to the site. The building has enough space to house the turbine, condenser and auxiliary boiler unit. The site has ample solar radiation for about 300 sunny days. The monthly average direct normal irradiance (DNI) and monthly average temperature for the site have been shown in Fig. 5.1.

5.2.2 Solar Field

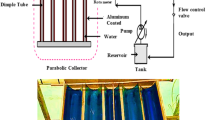

The solar concentrators used in the system are solar generator 4 (SG4) BigDish, developed by ANU (Lovegrove et al. 2011). These are 520 m2 parabolic dishes with dual-axis tracking fitted with a high-efficiency receiver (Pye et al. 2016). Analysing the solar radiation data, it is found that the site has the potential to provide optimum solar energy from 8 to 16th h of a typical day. As the NREL data counts the hour between 00:00 and 01:00 h as the zeroth hour, operation from 8 to 16th h will be 08:00–17:00 h, 9 h in total.

The layout of the dishes should be such that the adjacent dishes do not obstruct and cast a shadow when the sun is on the horizon. For the location Elevation (α) and Azimuth (γ) angles were calculated. It was found that between 8th to 16th h for each day throughout the year, the smallest value of α is 14.10°. This was in the morning, on the 8th h of 11th January. Corresponding γ angle was found to be 58.74°. The parabolic dishes were arranged with this orientation in mind. At this orientation, there should not be any shadow being cast on the adjacent dish. All other values of α and γ will be so that they will not cast any shadow. For 1 MW output from the system, the solar field designed consists of 14 SG4 solar dishes of 520 m2 size will be required considering designed DNI of 700 W/m2. Figure 5.2 shows the placements of the proposed solar field near Muni Seva Ashram.

5.2.3 Design of Power Cycle

A power cycle is based on regenerative Rankine cycle with condensing turbine. Turbine has two bleeds, one goes to VARs chiller and other to the deaerator. The bleed to VARs depends on the cooling load requirements. Lower the demand more will be the steam available for the turbine to generate power and condense. Figure 5.3 shows the block diagram of the power cycle with VARs machine (VAM) and deaerator. The steam from the solar field enters the turbine at 65 bar(a) and 360 °C. The isentropic efficiency of the turbine is considered as 60%. Though the proposed system is capable of producing steam at pressure and temperature of the order of 160 bar and 500 °C, the turbine inlet pressure and temperature were selected based on 1 MW turbine available in the market. The first extraction of the steam at 8.5 bar(a) and 174.5 °C with a flow rate of 360 kg/h is supplied to VAM, and second extraction at 4.76 bar(a) is given to deaerator, remaining steam after expansion in turbine comes out at 0.2 bar(a) and goes to condenser. The condensate from the condenser is then pumped to the deaerator where it meets the condensate from VAM and extraction from the turbine. The condensate from the deaerator is then pumped to the boiler pressure and sent back to the solar field.

5.2.4 Vapour Absorption Chiller Calculations

The existing requirement for cooling to be met at the ashram is about 80 tonnes of refrigeration (TR) so a VAM chiller to provide 80 TR for space cooling is selected. Looking at the daily temperature profile of the location, the maximum temperature was found to be 45 °C. The required tonnage of cooling is reduced at lower temperatures, assuming that all the other factors that contribute as heat loads do not vary. The VARs selected is a Double Effect VAM Chiller using LiBr-Water solution as a refrigerant with an operating pressure of 8.5 bar(a) with the steam flow rate of 360 kg/h at full load.

5.3 Results and Discussion

The proposed system has been simulated using MATLAB and the results of the simulation are presented in Figs. 5.4, 5.5 and 5.6. Figure 5.4 shows the monthly average refrigeration supplied, and the results represent a total of 15870 TR, an average of 43.47 TR each day of the year, with a peak in March, April and May when it is very much in demand. Figure 5.5 represents the monthly average electricity generation with a total of 2566 MWh of electricity generation throughout the year with about 250 MWh per month for almost eight months. Figure 5.5 represents cogeneration cycle efficiency, the results show that the system as a whole is expected to work within the range of 25–28% efficiency, which is a very good performance for the 1 MW scale power systems. The waste heat from the absorber and condenser of VAM may be utilized for low-temperature heating applications like the supply of hot water, or it may also be used for distillation application. Such a combined system will give power, cooling as well as heat and hence tri-generation system.

5.4 Conclusion

This paper presents the design and simulation of 1 MWe solar thermal power plant-based tri-generation system. This system is designed for the location of Muni Seva Ashram, at Goraj, Vadodara in Gujarat, India. The data analysis shows that the proposed site has sufficient DNI to run such a system.

The solar-based steam generator using ANU’s 520 m2 solar parabolic dish concentrators is used in the proposed tri-generation system to supply steam at 65 bar(a) and 360 °C producing 2566 MWh of electrical power generation throughout the year. The steam extracted from turbine powers a vapour absorption chilling unit to produce 15870 tons of refrigeration throughout the year with a peak in March, April and May when it is very much in demand. The proposed system is expected to work within a range of 25–28% of efficiency. The waste heat from the vapour absorption system may be used for low-grade heating applications.

Apart from the design of the power cycle, the layout of dishes is also designed for maximum steam generation from the solar field.

References

Behnam P, Arefi A, Shafii MB (2018) Exergetic and thermoeconomic analysis of a trigeneration system producing electricity, hot water, and fresh water driven by low-temperature geothermal sources. Energy Convers Manag 57:266–276

Colonna P, Gabrielli S (2003) Industrial trigeneration using ammonia-water absorption refrigeration systems (AAR). Appl Therm Eng 23(4):381–396

Energy Technology Perspectives (2015) International energy agency. https://webstore.iea.org/download/summary/542?fileName=Chinese-ETP-2015-ES.pdf. Accessed 03 July 2019

Gakkhar N, Soni MS, Jakhar S (2016) Second law thermodynamic study of solar assisted distillation system: a review. Renew Sustain Energy Rev 56:519–535. https://doi.org/10.1016/j.rser.2015.11.076

JNNSM. (2009) Mission document, ministry of new and renewable energy government of India. Jawaharlal Nehru national solar mission. https://mnre.gov.in/sites/default/files/uploads/mission_document_JNNSM.pdf. Accessed 03 July 2019

Le Lostec B, Galanis N, Millette J (2013) Simulation of an ammonia-water absorption chiller. Renew Energy 60:269–283

Lovegrove K, Burgess G, Pye J (2011) A new 500 m2 paraboloidal dish solar concentrator. Sol Energy 85(4):620–626

Nayak JK, Kedare SB, Banerjee R, Bandyopadhyay S, Desai NB, Paul S, Kapila A (2015) A 1 MW national solar thermal research cum demonstration facility at gwalpahari. Haryana, India, Curr Sci 109(8):1445–1457

Pye J, Hughes G, Abbasi E, Asselineau C.-A, Burgess G, Coventry J, Logie W, Venn F, Zapata J (2016) Development of a higher-efficiency tubular cavity receiver for direct steam generation on a dish concentrator. In: AIP conference proceedings

Sahoo U (2018) A polygeneration process concept for hybrid solar and biomass power plant: simulation, modelling, and optimization. Wiley, India

Soni MS, Gakkhar N (2014) Techno-economic parametric assessment of solar power in India: a survey. Renew Sustain Energy Rev 40:326–334. https://doi.org/10.1016/j.rser.2014.07.175

Sunil SMS (2017) Thermo-economic analysis of a solar-coal hybrid power plant. In: Proceedings of the 24th national and 2nd international ISHMT-ASTFE heat and mass transfer conference (IHMTC-2017). BITS Pilani, Hyderabad, India. https://doi.org/10.1615/ihmtc-2017.1940

Sunil SMS (2017) Integration of solar thermal energy in existing subcritical coal-fired power plant for fuel saving. In: ICAER 2017, 6th international conference on advances in energy research 2017. IIT Bombay, Mumbai, India

Sunil B, Soni MS (2019) Comparative performance assessment of a hybrid solar-coal power plant. Process Integr Optim Sustain 3(2):227–235. https://doi.org/10.1007/s41660-018-0066-x

Ummadisingu A, Soni MS (2011) Concentrating solar power—technology, potential and policy in India. Renew Sustain Energy Rev 15(9):5169–5175. https://doi.org/10.1016/j.rser.2011.07.040

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2020 The Author(s)

About this paper

Cite this paper

Soni, M.K., Soni, A. (2020). Design and Simulation of Solar Thermal Based Trigeneration System with 520 m2 Dish Collector. In: Sangwan, K., Herrmann, C. (eds) Enhancing Future Skills and Entrepreneurship. Sustainable Production, Life Cycle Engineering and Management. Springer, Cham. https://doi.org/10.1007/978-3-030-44248-4_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-44248-4_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-44247-7

Online ISBN: 978-3-030-44248-4

eBook Packages: EngineeringEngineering (R0)