Abstract

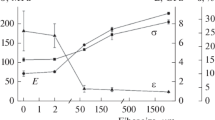

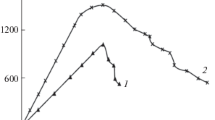

Nowadays, the choice of composite materials to manufacture medical orthopedic prostheses is largely accepted for its intrinsic resistance, ease of molding and machining, compatibility with human skin and also for economic aspects. Because of population aging and the need to repair broken or damaged human members, composite materials offer a very large variety of solutions to strongly satisfy such demands in the form of prostheses. These materials consist mainly of a consolidated resin reinforced with glass, carbon or natural fibers. Advantageous properties made them the most requested materials in the manufacturing of prosthetic devices for orthopedic use by people with movement disabilities. The present work considers a composite material made with carbon fibers, perlon (insulating layer) and an epoxy-based orthocyclic laminating resin. Both mechanical and morphological properties are analyzed. It is found that the composite made of carbon fibers/perlon/epoxy resin lower has lower mechanical resistance compared to carbon fiber/epoxy resin composite, but its adherence and its contact with human skin are ameliorated. For the fibrous reinforcements, carbon, glass or perlon, the mechanical properties on the proposed composite material (PVA- (C-4P-C) -PVA) are comparable to literature values. Based on uniaxial tensile tests, the elastic modulus is 626 MPa and the yield stress which is 57 MPa. Finally, SEM observations revealed that both composites exhibit similar damage mechanisms with higher intensity when perlon is present. This is due to the nature of the perlon in the composite material which exhibits more anisotropy. The main encountered damage mechanism is laminate decohesion which takes places between carbon plies and perlon. Such condition contributes to more interlaminar delamination and more brittleness of the material when subjected to high loads.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- CF::

-

Carbon fiber

- GF::

-

Glass fiber

- PF::

-

Perlon fiber

- TP::

-

Themoplastic resin

- TS::

-

Thermosetting resin

- ONAAPH::

-

National Office of Accessories and Apparatuses for Disabled Persons

- PVA::

-

polyvinyl alcohol (film)

- E::

-

Elastic modulus (MPa)

- σy::

-

Yield stress (MPa)

- σf::

-

Failure stress (MPa)

- εf::

-

Failure strain (%)

References

Ambrosio, L.: Biomedical Composites, 2nd edn., p. 616. Elsevier Woodhead Publishing, Cambridge (2017)

Berthelot, J.M.: Matériaux Composites: Comportement Mécanique et Analyse des structures, 5ème Lavoisier, Paris (2012)

Rajak, D.K., Pagar, D.D., Menezes, P.L., Linul, E.: Fiber-reinforced polymer composites: manufacturing, properties, and applications. Polymers 11(10), 1667 (2019). https://doi.org/10.3390/polym11101667

Plummer, C.J.G., Bourban, P.-E., Månson, J.-A.E.: Polymer matrix composites: matrices and processing. In: Encyclopedia of Materials: Science and Technology, pp. 7388–7396 (2001). https://doi.org/10.1016/B978-0-12-803581-8.02386-9

Iftekhar, A.: Biomedical composites. In: Standard Handbook of Biomedical Engineering and design, Downloaded from Digital Engineering Library. McGraw-Hill (2004). www.digitalengineeringlibrary.com

Composites Market by Fiber Type (Glass Fiber Composites, Carbon Fiber Composites, Natural Fiber Composites), Resin Type (Thermoset Composites, Thermoplastic Composites), Manufacturing Process, End-use Industry and Region, Global Forecast to 2020–2024. https://www.marketsandmarkets.com/Market-Reports/composite-market-200051282.html

Lionel Gendre, L.: Matériaux composites et structures composites. https://eduscol.education.fr/sti/si-ens-cachan/. Reviewed October 2019

Hillock, R., Howard, S.: Utility of carbon fiber implants in orthopedic surgery: literature review, JISRF Reconstructive Rev. 4(1), 23–32

https://www.utsi.edu/research/carbonfiber/CF.htm. Reviewed 12 Aug 2013

ONAAPH Manufacturing protocol. Reviewed 2018

ISO 527–4: Plastiques — Détermination des propriétés en traction — Partie 4: Conditions d'essai pour les composites plastiques renforcés de fibres isotropes et orthotropes (1997)

ASTM D5083: Standard Test Method for Tensile Properties of Reinforced Thermosetting Plastics Using Straight-Sided Specimens (2017)

Berthelot, J.M., Lecorre, J.F.: Fissuration transverse et délaminage dans les stratifiés croisés essais monotones et essais de fatigue, XVe Congrès français de mécanique, Nancy (2001)

Fantozzi, G.: Rupture des matériaux : 1ère et 2ème parties, recueil, Département Génie physique des Matériaux et Génie Mécanique Développement, 5ème année, p. 447. INSA Lyon, France (1990)

Kahtan Al-Khazraji, K., Kadhim, J., Sahbah Ahmed, P.: Effect of reinforcement material on fatigue characteristics of trans-tibial prosthetic socket with PMMA matrix. In: The 4th International Scientific Conference of Salahaddin University-Su Erbil, Kurdistan, 18–20 October 2011

Walke, K.M., Pandure, P.S.: Mechanical properties of materials used for prosthetic foot: a review. IOSR J. Mech. Civil Eng. (IOSR-JMCE) (2017). e-ISSN: 2278–1684, p-ISSN: 2320–334X 61–65

Abbas, S.M.: Effects of composite material layers on the mechanical properties for partial foot prosthetic socket. Al-Nahrain J. Eng. Sci. (NJES) 21(2), 253–258 (2018)

Achouri, S., Redjel, B.: Experimental study and probabilistic analysis of the tensile fracture behavior of glass-perlon-acrylic reinforced composites for orthopedic use. Rev. Sci. Technol. Synthèse 29(59), 76 (2014)

Acknowledgements

The authors wish to express their gratitude towards the ONAAPH technicians of Annaba (Algeria) for raw material supply, facility operations, and fruitful discussions. Parts of this work are conducted within 2 PRFU projects authorized by the DGRSDT of the Algerian Ministry of Higher Education and Scientific Research. https://www.univ-annaba.dz

Project code: A11N01UN230120190010, “Contribution à l’étude du comportement d’un matériau composite à base de fibres de carbone pour la réalisation de prothèses orthopédiques”.

Project code: A11N01UN230120190008 “Etude du comportement mécanique et de la durée de vie restante des tubes en PE soumis aux conditions de l’exploitation et de l’environnement”.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Alimi, L. et al. (2020). Mechanical Strength Analysis and Damage Appraisal in Carbon/Perlon/Epoxy Composite for Orthopedic Prostheses. In: Safi, B., Daoui, A., Mechakra, H., Ghernouti, Y. (eds) Proceedings of the 4th International Symposium on Materials and Sustainable Development. ISMSD 2019. Springer, Cham. https://doi.org/10.1007/978-3-030-43211-9_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-43211-9_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-43210-2

Online ISBN: 978-3-030-43211-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)