Abstract

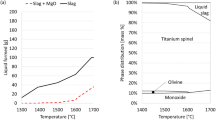

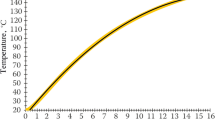

MINTEK in South Africa is investigating the effect of preheating on smelter operations mainly to reduce the electrical energy requirement for smelters. A pilot-scale facility is being developed which includes a one t/h rotary kiln coupled to an electric arc furnace (EAF) optionally served by either an alternating current (AC) or direct current (DC) power supply. The facility also includes integrated materials handling, product handling, and water-cooling systems. It allows for the evaluation of cold versus hot feed (up to 900 °C) on smelter operations over periods of 2–3 weeks continuous operation. The first application will study the effect of preheating on the smelting of titaniferous magnetite (15% TiO2) using a DC-furnace as part of the TiMag project. The second application will evaluate the effect of preheating on the production of high carbon ferromanganese (targeting 78%Mn) using an AC-furnace as part of the PreMa project. The paper presents the results of the basic engineering of the project.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Steinberg WS, Geyser W, The history and development of the pyrometallurgical processes at Evraz Highveld Steel & Vanadium, p 14

Steenkamp J, Bam W, Ringdalen E, Mushwana M, Hockaday S, Sithole N (2018) Working towards an increase in manganese ferroalloy production in South Africa—a research agenda. J South Afr Inst Min Metall 118(6):645–654

Anonymous (2019) Eskom tarrifs & charges booklet 2019/2020. Tech. Rep., Eskom, Apr. 2019

Jones R (2014) DC arc furnaces—past, present, and future. In: Celebrating the megascale: proceedings of the extraction and processing division, symposium in honour of D.G.C. Robertson. San Diego, California, pp 129–139

ASTM-A99 (2009) Standard specification for ferromanganese. 2003: ASTM International, West Conshohocken, PA

Ahmed A, Halfa H, El-Fawakhry M, El-Faramawy H, Eissa M (2014) Parameters affecting energy consumption for producing high carbon ferromanganese in a closed submerged arc furnace. Int J Iron Steel Res 21(7):666–672

Olsen S, Tangstad M, Lindstad T (2007) Production of manganese ferroalloys. Tapir Academic Press, Trondheim, Norway

Swamy K, Robertson D, Calvert P, Kozak D (2001) Factors affecting carbon consumption in the production of high carbon ferromanganese, Quebec City, Canada, pp 293–301

Healy G (1990) Ferromanganese material and energy balances calculation of electrical resistance mix. In: Proceedings of the international symposium on ferrous and non-ferrous alloy processes, Hamilton, Canada, pp 85–96

Seider W, Seader J, Lewin D (2004) Product and process design principles—synthesis, analysis, and evaluation, 2nd edn. Wiley & Sons, Inc., New York, USA

Acknowledgements

The TiMag project is funded by the Medium Term Expenditure Framework (MTEF) funding by the South African National Treasury. The PreMa project is funded by the European Union’s Horizon 2020 Research and Innovation Programme under Grant Agreement No 820561 and industry partners: Transalloys, Eramet, Ferroglobe, OFZ, and Outotec.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Steenkamp, J.D., Denton, G.M., Pieters, T. (2020). Upgrading Pilot-Scale Facility at MINTEK to Evaluate the Effect of Preheating on Smelter Operations. In: Peng, Z., et al. 11th International Symposium on High-Temperature Metallurgical Processing. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36540-0_28

Download citation

DOI: https://doi.org/10.1007/978-3-030-36540-0_28

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36539-4

Online ISBN: 978-3-030-36540-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)