Abstract

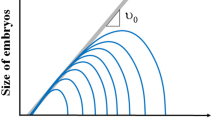

Heat treatment of cast aluminum alloy parts enables the formation and distribution of nano-sized precipitates through an optimum sequence including solutionizing, quenching, and artificial aging. Quaternary alloys are particularly challenging, and the present study aims to understand and outline the precipitation kinetics in the foundry AlSi7Cu0.5Mg0.3 alloy. Using techniques like differential scanning calorimetry (DSC), transmission electron microscopy (TEM), LKSZ kinetic equations, and microhardness testing, the precipitation kinetics was quantitatively characterized. Activation energies of the phase transformations were extracted using the Kissinger analysis of non-isothermal DSC runs conducted at different stationary heating rates. Finally, a first evaluation of the interfacial mobility of precipitates in this alloy was made using the developed methodology.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Larouche D (2017) Mixed mode growth of an ellipsoidal precipitate: analytical solution for shape preserving growth in the quasi-stationary regime. Acta Mater 123:188–196

Naseri T, Larouche D, Martinez R, Breton F (2018) Mixed-mode growth of a multicomponent precipitate in the quasi-steady state regime. Mater Theory 2. https://doi.org/10.1186/s41313-018-0011-y

Heugue P, Larouche D, Breton F, Martinez R, Chen XG (2019) Evaluation of the Growth Kinetics of θ′ and θ-Al2Cu precipitates in a binary Al-3.5 Wt Pct Cu alloy. Metall Mater Trans A 50:3048–3060. https://doi.org/10.1007/s11661-019-05227-8

Heugue P, Larouche D, Breton F, Massinon D, Martinez R, Chen X-G (2019) Precipitation kinetics and evaluation of the interfacial mobility of precipitates in an AlSi7Cu3.5Mg0.15 cast alloy with Zr and V additions. Metals 9:777

Edwards GA, Stiller K, Dunlop GL, Couper MJ (1998) The precipitation sequence in Al–Mg–Si alloys. Acta Mater 46:3893–3904

Ding L, Jia Z, Nie J-F, Weng Y, Cao L, Chen H, Wu X, Liu Q (2018) The structural and compositional evolution of precipitates in Al–Mg–Si–Cu alloy. Acta Mater 145:437–450. https://doi.org/10.1016/j.actamat.2017.12.036

Lombardi A, D’Elia F, Ravindran C, MacKay R (2014) Replication of engine block cylinder bridge microstructure and mechanical properties with lab scale 319 Al alloy billet castings. Mater Charact 87:125–137. https://doi.org/10.1016/j.matchar.2013.11.006

Dutta I, Allen SM (1991) A calorimetric study of precipitation in commercial aluminium alloy 6061. J Mater Sci Lett 10:323–326

Li H, Yan Z, Cao L (2018) Bake hardening behavior and precipitation kinetic of a novel Al–Mg–Si–Cu aluminum alloy for lightweight automotive body. Mater Sci Eng, A 728:88–94. https://doi.org/10.1016/j.msea.2018.05.014

Buha J, Lumley RN, Crosky AG (2008) Precipitation and solute distribution in an interrupted-aged Al–Mg–Si–Cu alloy. Phil Mag 88:373–390. https://doi.org/10.1080/14786430701847949

Chen SP, Mussert KM, Van Derzwaag S (1998) Precipitation kinetics in Al6061 and Al6061-alumina particle composite. J Mater Sci 4477–4483

Buha J, Lumley RN, Crosky AG, Hono K (2007) Secondary precipitation in an Al–Mg–Si–Cu alloy. Acta Mater 55:3015–3024. https://doi.org/10.1016/j.actamat.2007.01.006

Povoden-Karadeniz E (2015) Thermodynamic Data from MatCalc Database ‘mc_al.tdb’. 2.030 edn

Yang W, Wang M, Jia Y, Zhang R (2011) Studies of orientations of β″ precipitates in Al–Mg–Si–(Cu) alloys by electron diffraction and transition matrix analysis. Metall Mater Trans A 42:2917–2929. https://doi.org/10.1007/s11661-011-0680-5

Ding L, Jia Z, Zhang Z, Sanders RE, Liu Q, Yang G (2015) The natural aging and precipitation hardening behaviour of Al–Mg–Si–Cu alloys with different Mg/Si ratios and Cu additions. Mater Sci Eng, A 627:119–126. https://doi.org/10.1016/j.msea.2014.12.086

Chakrabarti DJ, Laughlin DE (2004) Phase relations and precipitation in Al–Mg–Si alloys with Cu additions. Prog Mater Sci 49:389–410. https://doi.org/10.1016/s0079-6425(03)00031-8

Biswas A, Siegel DJ, Seidman DN (2014) Compositional evolution of Q-phase precipitates in an aluminum alloy. Acta Mater 75:322–336. https://doi.org/10.1016/j.actamat.2014.05.001

Matsuda K, Ikeno S, Uetani Y, Sato T (2001) Metastable phases in an Al–Mg–Si alloy containing copper. Metall Mater Trans A 32:1293–1299. https://doi.org/10.1007/s11661-001-0219-2

Eskin DG (2003) Decomposition of supersaturated solid solutions in Al–Cu–Mg–Si alloys. J Mater Sci 38:279–290. https://doi.org/10.1023/a:1021109514892

Andersen SJ, Zandbergen HW, Jansen J, TrÆholt C, Tundal U, Reiso O (1998) The crystal structure of the β″ phase in Al–Mg–Si alloys. Acta Mater 46:3283–3298. https://doi.org/10.1016/S1359-6454(97)00493-X

Starink MJ, Zahra AM (1998) β′ and β precipitation in an Al–Mg alloy studied by DSC and TEM. Acta Mater 46:3381–3397. https://doi.org/10.1016/s1359-6454(98)00053-6

Vissers R, van Huis MA, Jansen J, Zandbergen HW, Marioara CD, Andersen SJ (2007) The crystal structure of the β′ phase in Al–Mg–Si alloys. Acta Mater 55:3815–3823. https://doi.org/10.1016/j.actamat.2007.02.032

Acknowledgements

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC) for financial support (NSERC Grant RDCPJ 468550—548 14) and also to Montupet and Rio Tinto ARDC teams for their collaboration. The authors are also grateful to J.-P. Masse from (CM)2 at École Polytechnique de Montreal for his strong collaboration in conducting the TEM observations and Daniel Marcotte, Nathalie Moisan, Hervé Plancke, and Dr. Marc Choquette for sharing their valuable knowledge and technical expertise.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Heugue, P., Larouche, D., Breton, F., Martinez, R., Chen, X.G., Massinon, D. (2020). Precipitation Kinetics and Evaluation of the Interfacial Mobility of Precipitates in an AlSi7Cu0.5Mg0.3 Cast Alloy. In: TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-36296-6_167

Download citation

DOI: https://doi.org/10.1007/978-3-030-36296-6_167

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-36295-9

Online ISBN: 978-3-030-36296-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)