Abstract

The rapid, efficient and non-destructive 3D morphological data acquisition of plants are great significance to the study of digital plant, functional structural plant model and crop phenotype. This paper discusses 3D data acquisition methods for smaller plant organs, which take maize grain as an example. Smartscan and Micro-CT scanning can be used to obtain the morphological data of the grains. The efficiency, accuracy, processing of data in two scanning ways are compared and analyzed. The results shows that the Micro-CT is more suitable for obtaining information of internal structure of maize grain. While grain morphology in SmartScan can get better visualization than Micro-CT, and the former one can also obtain image texture information. These two kinds of methods for volume measurement have good consistency except for Denghai 605. The study will provide theoretical basis for obtaining 3D data of plant organs at smaller scales.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the popularity of three-dimensional (3D) data acquisition technology and equipment, the measurement, analysis and 3D reconstruction of plant morphology based on 3D data have become a hotspot in plant science [1]. 3D plant modeling is the basis of digital plants [2, 3] and functional structural plant models (FSPMs) [4], and also an important part of crop phenotype studies [5]. Nowadays, the 3D morphological modeling of plant leaves, stems, ears and other organs have been studied [6,7,8,9]. However, there are few researches on small-scale plant organs such as grains. Grains, the most direct factors of yield, will indirectly affect the morphological structure of the plants.

Compared with the traditional data acquisition method, Smartscan and Micro-CT can all be used to obtain non-contact and high precision 3D data measurement. With scanning speed, high precision, all digital and detailed features can be obtained [10, 11]. Smartscan (white light stripes projection scanning) is a micro-projection technology (MPT). Thought high-precision optical measurement technology, scanners could measure the entire surface of the object. The accuracy of acquired point cloud achieve sub-millimeter range, and the operation resolution are excellent [12]. At present the main application areas of MPT are quality control, reverse engineering and 3D modeling, especially works of art and archaeological research and digital archiving [13, 14]. Micro-CT (micro-computer tomography) is a non-contact 3D imaging technique that can clearly acquire the external configuration and internal micro structures of the sample without destroying itself. It has a great application value for micro-scale plant organs or plant tissue [15, 16].

To provide data and technical support for micro-scale plant visualization, choosing maize grain as an example, and compare two kinds of 3D morphological acquisition methods. The main results are include data acquisition efficiency, scanning precision, scanning effect, scanning scope, and scanning condition requirement.

2 Material and Method

2.1 3D Data Acquisition Devices

SmartScan3D-5.0 color 3D scanner (AICON three-dimensional Systems GmbH, Braunschweig, Germany) is used as white light stripe projection 3D scanning, which mainly composed of host computer (high-end professional workstation), sensor (white-blue LED light source; two professional high resolution CCD digital camera in left and right) and a turntable which can be rotated by 180°, as shown in Fig. 1(a). For the small-scale plant organs, S-30 digital lens is selected for grains point cloud acquisition. Its measuring range is between 30–1500 mm and the accuracy is ±7 μm. The maize grains are scanned from six sides, as shown in Fig. 2. The data acquisition time is basically 0.5–1 h.

We select Bruker Micro-CT (SkyScan 1172) to acquire the 3D morphological data, which provide 40 kV/250 mA X-ray source and 1.3 megapixel CCD camera. The measuring range is between 27–50 mm, as shown in Fig. 1(b). When using Micro-CT to scan maize grains, the sample is placed in the equipment. It is necessary to adjust the pixel size and exposure time of the sample and X-ray source, in order to ensure the sample is in the middle of view field, so that the scanned 3D image is more accuracy. 3D structure of the splicing and volume calculation needs the support of the software CT Vox and CTAn.

2.2 Material

Dent grain (Yedan13, Liangyu99 and Denghai605) and semi-dent grain (Nongda108, Jingdan38 and Jingke665) are selected as different grain samples, as shown in Fig. 3. These selected maize cultivars are commonly used varieties with high stable yield and good quality. By using the two 3D data acquisition equipment, the 3D structural data of grains are obtained, and the advantages and disadvantages of the two methods will be compared.

3 Result and Discussion

The high quality 3D model is important for the measurement, simplification, and parameterization of control points and key trait of the sample. SmartScan and Micro-CT have their own adaptation scenarios and ranges. Therefore, these two 3D data acquisition equipment with respect to data acquisition efficiency, accuracy, scanning range, and post-processing are compared and analyzed.

3.1 Evaluation of Data Acquisition Efficiency, Accuracy, and Post-processing

Two kinds of 3D data acquisition methods have differences in data acquisition efficiency, scanning accuracy, scanning range and post-processing.

Data Acquisition Efficiency. SmartScan scanning process is longer than Micro-CT. The former need to scan every six sides of the surface, and search for same cloud points which between two adjacent scanning position. When using Micro-CT, it only need to put the grain into the device and set the relevant parameters, then the 3D structure of the grain can be directly output.

Scanning Accuracy. The comparison can be seen in Table 1, SmartScan for the external structure can achieve a better level and its accuracy is μm level. Micro-CT can detect the structure of the internal contents of the grain, the accuracy is higher than the SmartScan, which can also reach the μm level.

Scanning Range. SmartScan and Micro-CT are best suited for indoor environments, and the former one is more portable than the latter.

Post-processing. Unlike Smartscan, Micro-CT does not require multi-station scanning and splicing. The geometric model can directly generate. While Micro-CT also need to scan out the gray-scale and binarized 3D model can calculate the morphological parameters.

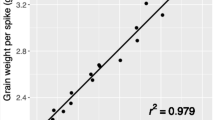

3.2 Volume Measurement

For maize grains, the volume is one of the most important representations of external structure. The data obtained by two kinds of 3D data acquisition equipment need to further processing. The point cloud model constructed by SmartScan need use corresponding software (3D Reshaper or Geomagic Studio) to produce corresponding volume of closed geometric model. Micro-CT output grayscale 3D models need binarized, and Bruker’s CTAn is used to calculate the volume and other parameters. Comparing the differences between two kinds of acquisition methods, and combining with the 3D visualization of the grid data (Table 1), it can more intuitively contrast the grains structural differences.

From the 3D data in Table 1 and Fig. 4, it can be seen that the two kinds of 3D data acquisition methods have no obvious difference in other varieties except for Denghai605, which show the application of two devices in grain structures. Denghai605 in the two methods has big difference may built on the 3D model of SmartScan which cannot fill a small hole, so that the geometric model is not closed, which makes the volume calculation becomes larger.

In summary, two methods can be used to obtain the external volume data, SmartScan effect is better than Micro-CT, the latter one can obtain internal embryo and endosperm and other related parameters, which is better than the acquisition of external volume data.

4 Conclusions

Through the above analysis and comparison, it is feasible to obtain 3D point cloud data of maize grains by using SmartScan and Micro-CT instruments. On the basis of the acquired morphological data, the evaluation of data acquisition efficiency, precision and post-processing have the following conclusions:

-

(1)

As SmartScan need scan different sides to find same cloud points for splicing, Micro-CT’s advantage is more obvious than Smartscan.

-

(2)

Both SmartScan and Micro-CT can reach μm level with high accuracy and cloud promise the morphological details of grains. However, Micro-CT has no surface color texture.

-

(3)

With respect to scanning range, both can be used indoors, Micro-CT is as less portable as SmartScan.

-

(4)

For post-processing of scanning, SmartScan need to remove the background impurities and the merger of the simplified processing, but Micro-CT only need to remove the contents.

-

(5)

The two methods are less difference of volume calculation, but SmartScan have better effect than Micro-CT.

To summarize, two scanning way can be used for maize grains 3D morphological data acquisition. Micro-CT is better for analyzing the interior morphometrics of the grain and SmartScan is more suitable to acquire the 3D appearance of grains.

References

Jonathon, A.G., Michael, P., Andrew, P.F., et al.: Approaches to three-dimensional reconstruction of plant shoot topology and geometry. Funct. Plant Biol. 44(1), 62–75 (2017)

Zhao, C., Lu, S., Guo, X., et al.: Advances in digital plant research: three-dimensional digitization of plant morphology. China Agric. Sci. 48(17), 3415–3428 (2015)

Zhao, C., Lu, S., Guo, X., et al.: Digital plant and its technical system. China Agric. Sci. 43(10), 2023–2030 (2010)

Vos, J., Evers, J.B., Buck-Sorlin, G.H., et al.: Functional–structural plant modelling: a new versatile tool in crop science. J. Exp. Bot. 61(8), 2101–2115 (2010)

Robert, T.F., Mark, T.: Phenomics–technologies to relieve the phenotyping bottleneck. Trends Plant Sci. 16(12), 635–644 (2011)

Fang, H., Hu, L., He, R., et al.: Study on three-dimensional information collection method of plant. Chin. J. Agric. Eng. 28(3), 142–147 (2012)

Xiao, B., Guo, X., Wang, J., et al.: Study on morphological modeling and mesh simplification of maize leaves. J. Agric. Sci. 40(4), 693–697 (2007)

Wen, W., Guo, X., Lu, X., et al.: Construction of three-dimensional template resource library for maize. J. Agric. Mech. 47(8), 266–272 (2016)

Fang, W., Feng, H., Yang, W., et al.: High-throughput volumetric reconstruction for three dimensional wheat plant architecture studies. J. Innov. Opt. Health Sci. 9(05), 137–165 (2016)

Zhang, J., Li, Z., Zhang, N., et al.: Study on three-dimensional information acquisition and reconstruction of crops based on measured data. J. Huazhong Agric. Univ. 32(4), 126–134 (2013)

Wei, X., Xiao, B., Guo, X., et al.: Application of three-dimensional laser scanning technology in plant scanning. Chin. Agric. Sci. Bull. 26(20), 373–377 (2010)

Mara, H., Breuckmann, B., Lang-Auinger, C.: Multi-spectral high-resolution three-dimensional-acquisition for rapid archaeological documentation and analysis. In: 2009 17th European IEEE Signal Processing Conference, pp. 1205–1209 (2009)

Akca, D., Gruen, A., Breuckmann, B., et al.: High definition three-dimensional-scanning of arts objects and paintings. 2, 50–58 (2007)

Bretzke, K., Conard, N.J.: Evaluating morphological variability in lithic assemblages using three-dimensional models of stone artifacts. J. Archaeol. Sci. 39(12), 3741–3749 (2012)

Yang, W., Xu, X., Bi, K., et al.: Adaptive region of interest method for analytical micro-CT reconstruction. J. X-ray Sci. Technol. 19(1), 23–33 (2011)

Du, J., Zhang, Y., Guo, X., et al.: Micron-scale phenotyping quantification and three-dimensional microstructure reconstruction of vascular bundles within maize stalks based on micro-CT scanning. Funct. Plant Biol. 44(1), 10–22 (2017)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (31601215), the Natural Science Foundation of Beijing Municipality (4162028), the Beijing Academy of Agricultural and Forestry Sciences Youth Research Fund (QNJJ201625), the Scientific and Technological Innovation Team of Beijing Academy of Agricultural and Forestry Sciences (JNKYT201604) and the National Technology Research and Development Program of China (2013AA102404-02).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 IFIP International Federation for Information Processing

About this paper

Cite this paper

Yu, Z., Wen, W., Guo, X., Lu, X. (2019). Study on Three-Dimensional Data Acquisition of Crop Grains. In: Li, D., Zhao, C. (eds) Computer and Computing Technologies in Agriculture XI. CCTA 2017. IFIP Advances in Information and Communication Technology, vol 546. Springer, Cham. https://doi.org/10.1007/978-3-030-06179-1_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-06179-1_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-06178-4

Online ISBN: 978-3-030-06179-1

eBook Packages: Computer ScienceComputer Science (R0)