Abstract

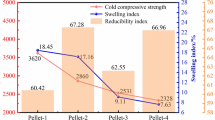

With increasing application of oxygen-enriched or even oxygen blast furnace ironmaking technologies, more intensive indirect reduction, followed by softening and melting, of iron ore pellets may take place in the blast furnace . In this study, the correlation between reduction degree and softening and melting properties of pellets was investigated. The results showed that with the increased of the reduction degree , the softening start temperature (Ts) of pellets did not change significantly and melting start temperature (Tm) obviously increased. The dropping temperature of the pellets slightly increased with the reduction degree of the pellets increase. Since the increased temperature range of the softening zone interval (ΔTS/°C) of the pellet was greater than the reduced temperature range of the melting zone interval (ΔTM/°C), the range of the cohesive of the pellet was increased. The permeability of the pellets was obviously improved as the reduction degree increased. This study provided important guidance for blast furnace production under high reduction degree conditions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Du SD, Chen WH, Lucas J (2007) Performances of pulverized coal injection in blowpipe and tuyere at various operational conditions. Energy Convers Manag 48:2069–2076

Wijayanta AT, Alam MS, Nakaso K, Fukai J, Kunitomo K, Shimizu M (2014) Combustibility of biochar injected into the raceway of a blast furnace. Fuel Process Technol 117:53–59

Guo BY, Zulli P, Rogers H, Mathieson JG, Yu AB (2005) Three-dimensional simulation of flow and combustion for pulverized coal injection. ISIJ Int 45:1272–1281

Shen YS, Guo BY, Yu AB, Maldonado D, Austin P, Zulli P (2008) Three-dimensional modelling of coal combustion in blast furnace. ISIJ Int 48:777–786

Shen YS, Guo BY, Yu AB, Zulli P (2009) A three-dimensional numerical study of the combustion of coal blends in blast furnace. Fuel 88:255–263

Babich A, Gudenau HW, Formoso A, Mavrommatis K, Froehling C, Garcia L (2002) Choice of technological regimes of a blast furnace operation with injection of hot reducing gases. Rev Metal 38:288–305

Meijer K, Denys M, Lasar J, Birat JP, Still G, Overmaat B (2009) ULCOS: ultra-low CO2. Ironmaking Steelmaking 36:249–251

Zuo GQ, Hirsch A (2009) The trial of the top gas recycling blast furnace at LKAB’s EBF and scale-up. Metall Res Technol 106:387–392

Danloy G, Berthelemot A, Grant M, Borlée J, Sert D, van der Stel J, Jak H, Dimastromatteo V, Hallin M, Eklund N, Edberg N, Sundqvist L, Sköld B-E, Lin R, Feiterna A, Korthas B, Müller F, Feilmayr C, Habermann A (2009) ULCOS-pilot testing of the low-CO2 blast furnace process at the experimental BF in Luleå. Metall Res Technol 106:1–8

An XW, Wang JS, Lan RZ, Han YH, Xue QG (2013) Softening and melting behavior of mixed burden for oxygen blast furnace. J Iron Steel Res Int 20:11–16

Desai B, Ramna RV, Sathaye JM (2008) Effect of hot reducing gas (HRG) injection on blast furnace operational parameters: theoretical investigation. Ironmaking Steelmaking 35:43–50

Qi YH, Yan DL, Gao JJ, Zhang JC, Li MK (2011) Study on industrial test of the oxygen blast furnace. Iron Steel 46:6–8

Kaushik P, Fruehan RJ (2006) Mixed burden softening and melting phenomena in blast furnace operation part 2—mechanism of softening and melting and impact on cohesive zone. Ironmaking Steelmaking 33:520–528

Kaushik P, Fruehan RJ (2007) Mixed burden softening and melting phenomena in blast furnace operation part3—mechanism of burden interaction and melt exudation phenomenon. Ironmaking Steelmaking 34:10–22

Chung SH, Kim KH, Sohn I (2015) DRI from recycled iron bearing wastes for lower carbon in the blast furnace. ISIJ Int 55:1157–1164

She XF, Wang JS, Liu JZ, Zhang XX, Xue QG (2014) Increasing the mixing rate of metalized pellets in blast furnace based on the high-temperature interactivity of iron bearing materials. ISIJ Int 54:2728–2736

Wu SL, Han HL, Xu HF, Yan LJ (2010) Research on mechanism of interaction between sinter and lump ores in blast furnace. Chin J Process Eng 10(Suppl):37–42

Deng SQ, Che CR, Yan LJ (1993) Study on carburization of iron in upper part of blast furnace. Iron Steel 28:12–16

Deng SQ, Shi YX, Wang Q, Li CY (1992) Carburization of hot metal in low part of BF. Iron Steel 27:5–14

Kaspersma JH, Shay RH (1981) Carburization of iron by CO-based mixtures in nitrogen at 925 C. Metall Mater Trans B 12:77–83

Murakami T, Fukuyama H, Nagata K (2001) Mechanisms of carburization and melting of iron by CO gas. ISIJ Int 41:209–215

Asano R, Sasaki Y, Ishii K (2002) Carburization of Iron by Ar–CO–H2 at 1523 K. ISIJ Int 42:121–126

Murakami T, Ohno M, Suzuki K, Owaki K, Kasai E (2017) Acceleration of carburization and melting of reduced iron in iron ore-carbon composite using different types of carbonaceous materials. ISIJ Int 57:1928–1936

Ohno K, Miki T, Hino M (2004) Kinetic analysis of iron carburization during smelting reduction. ISIJ Int 44:2033–2039

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Pan, YZ., Zhang, AJ., Lin, L., Wang, JS., Feng, HX., Lin, QS. (2019). Correlation Between Reduction Degree and Softening and Melting Properties of Pellets. In: Jiang, T., et al. 10th International Symposium on High-Temperature Metallurgical Processing. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-05955-2_49

Download citation

DOI: https://doi.org/10.1007/978-3-030-05955-2_49

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-05954-5

Online ISBN: 978-3-030-05955-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)