Abstract

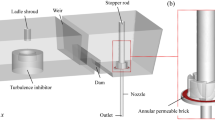

Gas-stirring has been an important method for secondary refining process of steel . The interaction of gas bubbles with the interface of liquid steel and molten slag has been simulated in this study. The model is based on the phase-field method for three-phase flow of steel -slag -gas. The micro-flow with a sharp interface tracking among the phases of an argon bubble floating in steel and motion across the steel -slag interface is obtained and discussed. By the model, it is found that there is a critical size for bubbles to pass the interface. Bubbles with a smaller size than the critical value will not pass the interface and settle under the slag phase when they contact with the interface for the first time. This result different from the past knows that the bubble will 100% pass the interface. A water model was set to invalidate the numerical model and the experiment result shows agreement with the numerical model.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Pehlke RD (1980) Steelmaking—the jet age. Metall Trans B 11(4):539–562

Jonsson L, Jönsson P (1996) Modeling of fluid flow conditions around the slag/metal interface in a gas-stirred ladle. ISIJ Int 36(9):1127–1134

Yamashita S, Iguchi M (2001) Mechanism of mold powder entrapment caused by large argon bubble in continuous casting mold. ISIJ Int 41(12):1529–1531

Thomas BG, Denissov A, Bai H (1997) Behavior of argon bubbles during continuous casting of steel. In: Steelmaking conference proceedings, vol 80. Iron and Steel Society of AIME, pp 375–384

Zhang L, Aoki J, Thomas BG (2006) Inclusion removal by bubble flotation in a continuous casting mold. Metall Mater Trans B 37(3):361–379

Li L, Li B, Liu Z (2017) Modeling of gas-steel-slag three-phase flow ladle metallurgy: Part II. Multi-scale mathematical model. ISIJ Int 57(11):1980–1989

Li B, Yin H, Zhou CQ, Tsukihashi F (2008) Modeling of three-phase flows and behavior of slag/steel interface in an argon gas stirred ladle. ISIJ Int 48(12):1704–1711

Tomiyama A, Celata GP, Hosokawa S, Yoshida S (2002) Terminal velocity of single bubbles in surface tension force dominant regime. Int J Multiph Flow 28(9):1497–1519

Wang L, Lee H-G, Hayes P (1996) Prediction of the optimum bubble size for inclusion removal from molten steel by flotation. ISIJ Int 36(1):7–16

Yang S, Liu W, Li J (2015) Motion of solid particles at molten metal–liquid slag interface. JOM 67(12):2993–3001

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Zhu, L., Liu, W., Yang, S., Li, J., Wang, F., Zhang, X. (2019). Numerical Simulation of Three-Phase Flow of Gas-Stirring Micro-phenomenon During Ladle Furnace Process. In: TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-05861-6_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-05861-6_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-05860-9

Online ISBN: 978-3-030-05861-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)