Abstract

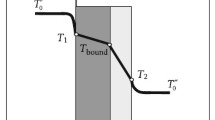

The formation of a freeze lining on the hot face of furnace sidewalls to increase campaign life is an accepted concept in industry today. This is achieved through a well-engineered sidewall cooling system typically consisting of cooled copper elements, either on their own or in combination with a refractory lining. The design of the lining/cooling system to form and maintain a competent freeze lining is discussed. Heat losses under normal operating conditions are calculated as an input to the furnace energy balance. The lining/cooling system is evaluated under extreme operating conditions as this ultimately determines campaign life. Variables to be evaluated include freeze lining thickness and formation rate, copper element temperatures, cooling medium used, and required cooling density and arrangement. Steady-state and transient thermal FEA are used as tools to evaluate the lining/cooling system design.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Burteaux M, Krafft W, Van Laar J, Traice FB, Vecchiola G (1987) Latest development in cooling and refractories of European blast furnaces. Steel Times 492–503

Joubert H, Nourse RB, Masters B, Hundermark R (2005) Copper cooling design, installation and operational results for the slag cleaning furnace at waterval smelter, Rustenburg Platinum, South Africa. In: 44th annual conference of metallurgists on nickel and cobalt 2005—challenges in extraction and production, Calgary, Alberta, Canada, pp 19–35

Eksteen JJ, Van Beek B, Bezuidenhout GA (2011) Cracking a hard nut: An overview of Lonmin’s operations directed at smelting of UG2-rich concentrate blends. Southern African Pyrometallurgy 2011 International Conference, Cradle of Humankind, South Africa, pp 231–251

Nelson LR, Stober F, Ndlovu J, De Villiers LPvS, Wanblad D (2005) Role of technical innovation on production delivery at the Polokwane smelter. In: 44th annual conference of metallurgists on nickel and cobalt 2005—challenges in extraction and production, Calgary, Alberta, Canada, pp 91–116

Jones RT (2005) An overview of Southern African PGM smelting. In: 44th annual conference of metallurgists nickel and cobalt 2005—challenges in extraction and production, Calgary, Alberta, Canada, pp 147–178

Hundermark R, De Villiers B, Ndlovu J (2006) Process description and short history of Polokwane smelter. In: Jones RT (ed) Southern African pyrometallurgy 2006 international conference, Cradle of Humankind, South Africa, pp 35–41

Mc Dougall I (2013) Sidewall design for improved lining life in a PGM smelting furnace. J Southern African Instit Mining Metallurg 113:631–636

Bryk P et al (1958) Flash smelting copper concentrates. Mining Eng 683–684

Yasuda Y, Motomura T, Kawasaki T (2014) Improvements to the operation of the Saganoseki flash smelting furnace. In: Conference of metallurgists

Marx F, Shapiro M, Henning B (2010) Application of high intensity refractory cooling systems in pyrometallurgical vessel design. The twelfth international ferroalloys congress. Helsinki, Finland, pp 769–778

Bhappu RR, Larson KH, Tunis RD (1994) Cyprus miami mining corporation smelter modernization project summary and status. In: Warren G (ed) EPD congress, pp 555–570

Kim MB, Lee WS, Lee YH (2000) The QSL lead slag fuming process using an Ausmelt furnace. In: Dutrizac JE et al (eds) Lead–Zinc 2000, The minerals, metals and materials society, pp. 331–343

MacRae A, Steinborn B (2018) Top submerged lance furnace lining cooling system upgrade. Extraction 2018, Ottawa, Quebec, Canada, pp 463–480

Viviers P, Hines K (2005) The New Anglo platinum converting project. First extractive metallurgy operators’ conference. AusIMM, Brisbane, pp 101–108

Nikolic S, Hogg B, Voigt P (2018) ISASMELT™—flexibility in furnace design. Extraction 2018, Ottawa, Quebec, Canada, pp 435–443

Joubert H (1997) MEng Thesis: analysis of blast furnace lining/cooling systems using computational fluid dynamics. Rand Afrikaans University (now University of Johannesburg), Johannesburg, South Africa

Kyllo AK, Gray NB, Papazoglou D, Elliot BJ (2000) Developing composite furnace module cooling systems. JOM February 2000, pp 66–67

Joubert H (2000) Designing for slag freeze linings on furnace sidewalls–an engineering perspective. In: 6th international conference on molten slags, fluxes and salts, Stockholm, Sweden-Helsinki, pp 1–11

Shaw A et al (2012) Challenges and solutions in PGM furnace operation: high matte temperature and copper cooler corrosion. In: 5th platinum conference 2012, Sun City, South Africa, pp 193–216

Thethwayo BM, Garbers-Craig AM (2010) Corrosion of copper coolers in PGM smelters. In: The 4th international platinum conference, platinum intransition ‘boom or bust’. The Southern African Institute of Mining and Metallurgy 2010:187–193

Verscheure K, Kyllo AK, Filzwieser A, Blanpain B, Wollants P (2006) Furnace cooling technology in pyrometallurgical processes. Sohn International Symposium, vol 4, TMS, pp 139–154

Campforts M, Jak E, Blanpain B, Patrick W (2009) Freeze lining formation of a synthetic lead slag—part 2: thermal history. Metall Mater Trans B 40:632–642

Campforts M, Blanpain B, Wollants P (2009) The importance of slag engineering in freeze lining applications. Metallurg Mater Trans B (2009) 40: pp. 643–655

Scholey KE, Richards GG, Samarasekera IV (1991) Heat-transfer phenomena in water-cooled zinc-fuming furnace jackets. Metall Trans B 22B:163–175

Kang S (1991) A model study of heat transfer and fluid flow in slag-cleaning furnaces. PhD thesis, University of Missouri-Rolla

Mills KC (1988) Thermal conductivities of liquid slags. In: 3rd International conference on molten slags and fluxes, June 1988, pp 229–234

Mills KC (2011) The estimation of slag properties. Short course presented as part of Southern Africa Pyrometallugy 2011 conference

Bezuidenhout JJ, Eksteen JJ (2009) Bradshaw SM (2009) CFD modelling of molten matte and slag flows in a circular three-phase smelting furnace. Prog Computat Fluid Dynam 9(6/7):316–324

Joubert H, Nikolic S, Bakker ML, Mc Dougall I (2016) Tenova Pyromet—cooled copper furnace elements. Copper 2016, Kobe, Japan, PY14–3, pp 955–965

Kennedy MW, Nos P, Bratt M, Weaver M (2013) Alternative coolants and cooling system designs for safer freeze lined furnace operation. Printed Ni–Co 2013:299–314

Kennedy MW, MacRae A, Jones RT, Kolbeinsen L, Nos P, Filzwieser A (2015) Some considerations for safer furnace cooling. As presented at COM 2015, Toronto, Canada, published by Canadian Institute of mining, metallurgy and petroleum

Kennedy MW (2012) Electric slag furnace dimensioning. In: Downey JP, Battle TP, White JF (eds) International smelting technology symposium: incorporating the 6th advances in sulfide smelting symposium. TMS, Orlando, FL, pp 279–290

Kennedy MW (2013). Slag furnaces—some issues for optimal design and operation. In: Proceedings of conference of metallurgist, Ralph Lloyd Harris memorial symposium. Montreal, QC, pp 411–426

Nelson LR, Hundermark RJ, Van der Merwe K (2015) Observations on the impact of furnace dimensions and power density on taphole integrity. In: Proceedings of the conference of metallurgists, COM 2015, Toronto, Canada, Paper no. 8877

Crivits T, Hayes PC, Jak E (2017) An investigation of factors influencing freeze lining behaviour. In: Mineral processing and extractive metallurgy IMM transactions section C, September 2017, pp 195–209

Crivits T, Hayes PC, Jak E (2018) Investigation of the effect of bath temperature on the bath-freeze lining interface temperature in the CuOx–FeOy–MgO–SiO2 system at copper metal saturation. Int J Mater Res 109(5):386–398

Crivits T, Hayes PC, Jak E (2018) Freeze linings in the Al2O3–CaO–SiO2 system. International Journal of Materials Research, 109, 2018, 7 (May), pp. 638–653

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Joubert, H., Mc Dougall, I. (2019). Designing Furnace Lining/Cooling Systems to Operate with a Competent Freeze Lining. In: TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-05861-6_113

Download citation

DOI: https://doi.org/10.1007/978-3-030-05861-6_113

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-05860-9

Online ISBN: 978-3-030-05861-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)