Abstract

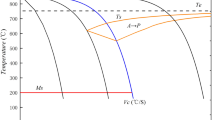

In order to investigate the effects of quenching temperature and cooling rate on the microstructure and mechanical properties of the U75V rail steel, Gleeble-3500 thermal simulator and tensile tester were applied and the dynamic CCT curves were obtained. The results show that low quenching temperature of 750 °C narrows the range of the cooling rate of only pearlite transformation, and the pearlite interlamellar spacing decreases with an increase in the cooling rate or the quenching temperature in this range. The minimum value of the pearlite interlamellar spacing is found to be 0.101 μm. At three quenching temperatures of 810, 780, and 750 °C, the microhardness increases with an increase in the cooling rate. In addition, the starting transformation temperature from austenite to pearlite does not exceed 700 °C, and the end temperature does not drop below 500 °C. The mechanical properties including yield strength, tensile strength, and total elongation of the selected specimens are improved as the pearlite interlamellar spacing decreases and meet the requirements. For the field production of the U75V rail steel, higher quenching temperature and a cooling rate of 3–5 °C/s are the best choices.

Similar content being viewed by others

References

W. Zhong, J.J. Hu, Z.B. Li, Q.Y. Liu, Z.R. Zhou, A study of rolling contact fatigue crack growth in U75V and U71Mn rails. Wear 271, 388–392 (2010)

H. Kang, D. Wu, X.M. Zhao, Surface temperature change of U75V 60 kg/m heavy rail during heat treatment. J. Iron. Steel Res. Int. 20(2), 33–37 (2013)

H. Kang, Y.H. Wang, D. Wu, X.M. Zhao, Y.M. Wang, Research on quenching equipment of rail head. Adv. Mater. Res. 145, 313–316 (2011)

J.G. Lenard, A study of temperature distribution in rails during intermittent cooling. J. Mater. Process. Technol. 25, 303–320 (1991)

L. Chen, F. Zhang, Z.Y. Zhang, R. Wei, Organization simulation analysis of the U75V cooling process. J. Metall. Eng. 3(1), 48–51 (2014)

M.X. Gao, H. Jia, J.J. Jiang, P.L. Wang, H. Song, S.Y. Yuan, Z.Q. Wang, The effect of initial cooling temperature on deformation of U75V heavy rail after cooling. Adv. Eng. Forum 2–3, 667–672 (2011)

J. Basu, S.L. Srimani, D.S. Gupta, Rail behaviour during cooling after hot rolling. J. Strain Anal. Eng. 39(1), 15–24 (2004)

S.L. Srimani, J. Basu, Nonlinear analysis of residual stresses in a rail manufacturing process by FEM. J. Strain Anal. Eng. 38, 261–268 (2003)

G. Li, H.Y. Cui, Analysis of 100-meter rail temperature field during cooling process before straightening by FEM. Int. J. Mod. Phys. B 23(6&7), 1203–1208 (2009)

M.X. Gao, H. Song, H. Jia, J.J. Jiang, S.H. Tong, S.Y. Yuan, Z.Q. Wang, Study on the temperature changing rules of U75V rail in the cooling process. Proc. Eng. 15, 4579–4584 (2011)

H. Kang, X.M. Zhao, D. Wu, Effect of air pressure on hardened layer of U75V 60 kg/m heavy rail after heat treatment. J. Harbin Inst. Technol. (New Ser.) 20(1), 52–56 (2013)

A.C. Ren, Y. Ji, G.F. Zhou, Z.X. Yuan, B. Han, Y. Li, Hot deformation behavior of V-microalloyed steel. J. Iron. Steel Res. Int. 17(8), 55–60 (2010)

Y. Liu, Experimental investigation of the mechanical properties of quenched rails for different quenching conditions using the temperature directly from rolling heating. J. Mater. Process. Technol. 63(1), 542–545 (1997)

R.Z. Luo, Study on dynamic CCT curve of U71Mn steel. Zhejiang Metall. 2, 38–40 (2013). (in Chinese)

Y.G. Wang, Y.L. Ma, B.F. Wang, Study on CCT curve determination and continuous cooling transformation of U71Mn steel. J. Baotou Univ. Iron Steel Technol. 14(3), 40–44 (1995). (in Chinese)

J.G. Zhang, X.G. Jing, TTT and CCT curve and microstructure analysis of U75V rail after induction heat treatment. Hot Work. Technol. 39(8), 168–170 (2010). (in Chinese)

A.C. Ren, Y. Ji, L.Q. Zhao, Phase transformation behavior of U75V steel under continuous cooling. Mater. Mech. Eng. 32(7), 15 (2008). (in Chinese)

B. Li, G.M. Zhu, G.M. Tao, Dynamic CCT curve of U75V steel for high-speed railway. J. Iron Steel Res. 26(11), 20–24 (2014). (in Chinese)

B. Li, G.M. Zhu, G.M. Tao, Effect of online slacking-quench on the microstructure and properties of U75V rail. Iron Steel 49(7), 101–193 (2014). (in Chinese)

Ministry of Railways of China, Rail ordering technical conditions. TB/T2344-201243 (2012). (in Chinese)

A.R. Marderand, B.L. Branefitt, The effect of morphology on the strength of pearlite. Metall. Trans. 7, 365–372 (1976)

Q.Y. Zhou, Y.H. Zhang, Properties and Related Process of Rail (China Railway Publishing House, Beijing, 2005). (in Chinese)

J.M. Hyzak, I.M. Bernstein, The role of microstructure on the strength and toughness of fully pearlitic steels. Metall. Trans. A 7(8), 1217–1224 (1976)

K. Han, G.D.W. Smith, V. Edmonds, Pearlite phase transformation in Si and V steel. Metall. Mater. Trans. 26(7), 1617–1631 (1995)

J. Ahmadi, M. Monirvaghefi, M. Salehi, Effect of pearlite interlamellar spacing on predominant abrasive wear mechanism of fully pearlitic steel. Trans. Mater. Heat Treat. 25(5), 1207–1213 (2004)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lan, Y., Zhao, G., Xu, Y. et al. Effects of Quenching Temperature and Cooling Rate on the Microstructure and Mechanical Properties of U75V Rail Steel. Metallogr. Microstruct. Anal. 8, 249–255 (2019). https://doi.org/10.1007/s13632-019-00530-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-019-00530-7