Abstract

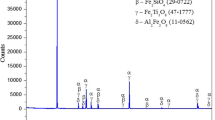

An innovative and sustainable carbothermal reduction and nitridation (CTRN) process of ilmenite (FeTiO3) using a mixture of polyethylene terephthalate (PET) and coal as the primary reductant under an H2–N2 atmosphere was proposed. The use of PET as an alternative source of carbon not only enhances the porosity of the pellets but also results in the separation of Fe from titanium oxycarbonitride (TiO x C y N z ) particles because of the differences in surface tension. The experiments were carried out at 1250°C for 3 h using four different PET contents ranging from 25wt% to 100wt% in the reductant. X-ray diffraction (XRD), scanning electron microscopy (SEM) in conjunction with energy-dispersive X-ray spectroscopy (EDX), and LECO elemental analysis were used to study the phases and microstructures of the reduced samples. In the case of 75wt% PET, iron distinctly separated from the synthesized TiO x C y N z phase. With increasing PET content in the sample, the reduction and nitridation rates substantially increased. The synthesis of an oxycarbonitride with stoichiometry of TiO0.02C0.13N0.85 with minimal intermediate titanium sub-oxides was achieved. The results also showed that the iron particles formed from CTRN of FeTiO3 exhibited a spherical morphology, which is conducive for Fe removal via the Becher process.

Similar content being viewed by others

References

A. Adipuri, Y. Li, G.Q. Zhang, and O. Ostrovski, Chlorination of reduced ilmenite concentrates and synthetic rutile, Int. J. Miner. Process., 100(2011), No. 3-4, p. 166.

A. Adipuri, G.Q. Zhang, and O. Ostrovski, Chlorination of titanium oxycarbonitride produced by carbothermal nitridation of rutile, Ind. Eng. Chem. Res., 48(2009), No. 2, p. 779.

D.P. Xiang, Y. Liu, M.J. Tu, Y.Y. Li, and W.P. Chen, Synthesis of nano Ti(C, N) powder by mechanical activation and subsequent carbothermal reduction-nitridation reaction, Int. J. Refract. Met. Hard Mater., 27(2009), No. 1, p. 111.

Y. Peng, H.Z. Miao, and Z.J. Peng, Development of TiCN-based cermets: mechanical properties and wear mechanism, Int. J. Refract. Met. Hard Mater., 39(2013), p. 78.

A. Mosbah, A. Calka, and D. Wexler, Rapid synthesis of titanium nitride powder by electrical discharge assisted mechanical milling, J. Alloys Compd., 424(2006), No. 1-2, p. 279.

A. Chrysanthou and N. Hassine, The observation and crystal structure of titanium oxycarbonitride, Powder Diffr., 9(1994), No. 3, p. 202.

D.T. Dam, K.D. Nam, H. Song, X. Wang, and J.M. Lee, Partially oxidized titanium carbonitride as a non-noble catalyst for oxygen reduction reactions, Int. J. Hydrogen Energy, 37(2012), No. 20, p. 15135.

J.R. Groza, J.D. Curtis, and M. Krämer, Field-assisted sintering of nanocrystalline titanium nitride, J. Am. Ceram. Soc., 83(2000), No. 5, p. 1281.

H. Kuwahara, N. Mazaki, M. Takahashi, T. Watanabe, X. Yang, and T. Aizawa, Mechanical properties of bulk sintered titanium nitride ceramics, Mater. Sci. Eng. A, 319-321(2001), p. 687.

J.J. Ru, Y.X. Hua, C.Y. Xu, Q.B. Zhang, D. Wang, and K. Gong, Synthesis of TiN from FeTiO3 by microwave-assisted carbothermic reduction–nitridation, J. Alloys Compd., 583(2014), p. 121.

A.P. Serro, C. Completo, R. Colaço, F. dos Santos, C.L. da Silva, J.M.S. Cabral, H. Araújo, E. Pires, and B. Saramago, A comparative study of titanium nitrides, TiN, TiNbN and TiCN, as coatings for biomedical applications, Surf. Coat. Technol., 203(2009), No. 24, p. 3701.

R. Gupta, S. Soni, and D.M. Phase, Improvement of oxidation resistance of TiCN films prepared by laser alloying, Appl. Phys. A, 118(2015), No. 1, p. 191.

T. Matsuda and H. Matsubara, Thermophysical and elastic properties of titanium carbonitrides containing molybdenum and tungsten, J. Alloys Compd., 562(2013), p. 90.

S.A. Rezan, G.Q. Zhang, and O. Ostrovski, Carbothermal reduction and nitridation of ilmenite concentrates, ISIJ Int., 52(2012), No. 3, p. 363.

Q.Y. Wang, J.X. Song, J.Y. Wu, S.Q. Jiao, J.G. Hou, and H.M. Zhu, A new consumable anode material of titanium oxycarbonitride for the USTB titanium process, Phys. Chem. Chem. Phys., 16(2014), No. 17, p. 8086.

S.A. Rezan, A. Adipuri, G.Q. Zhang, and O. Ostrovski, Carbothermal reduction and nitridation of ilmenite concentrates and chlorination of the reduced samples, [in] Proceedings of the XXV International Mineral Processing Congress (IMPC 2010), Brisbane, 2010, p. 1585.

S.A. Rezan, G.Q. Zhang, and O. Ostrovski, Phase development in carbothermal reduction and nitridation of ilmenite concentrates, High Temp. Mater. Processes, 31(2012), No. 4-5, p. 381.

S.Q. Jiao and H.M. Zhu, Electrolysis of Ti2CO solid solution prepared by TiC and TiO2, J. Alloys Compd., 438(2007), No. 1-2, p. 243.

M. Ma, D.H. Wang, W.G. Wang, X.H. Hu, X.B. Jin, and G.Z. Chen, Extraction of titanium from different titania precursors by the FFC Cambridge process, J. Alloys Compd., 420(2006), No. 1-2, p. 37.

X. Fu, Y. Wang, L. Xiong, and F. Wei, Enhancement of the low temperature chlorination of ilmenite with CCl4 by adding Cl2, J. Alloys Compd., 486(2009), No. 1-2, p. 365.

K.S. Geetha and G.D. Surender, Experimental and modelling studies on the aeration leaching process for metallic iron removal in the manufacture of synthetic rutile, Hydrometallurgy, 56(2000), No. 1, p. 41.

L.C. de Santa Maria, Preparation of soluble TiCl4 catalyst modified with some metal chlorides and its use for ethylene and propylene homopolymerization, Polymer, 36(1995), No. 1, p. 217.

R.O. Suzuki, T.N. Harada, T. Matsunaga, T.N. Deura, and K. Ono, Titanium powder prepared by magnesiothermic reduction of Ti2+ in molten salt, Metall. Mater. Trans. B, 30(1999), No. 3, p. 403.

D.S. van Vuuren, S.J. Oosthuizen, and M.D. Heydenrych, Titanium production via metallothermic reduction of TiCl4 in molten salt: problems and products, J. S. Afr. Inst. Min. Metall., 111(2011), No. 3, p. 141.

S.A. Rezan, G.Q. Zhang, O. Ostrovski, and L. Prentice, Carbothermal reduction and nitridation of titanium dioxide in a H2-N2 gas mixture, J. Am. Ceram. Soc., 94(2011), No. 11, p. 3804.

J.R. Dankwah, P. Koshy, and V. Sahajwalla, Reduction of FeO in EAF steelmaking slag by blends of metallurgical coke and end-of-life polyethylene terephthalate, Ironmaking Steelmaking, 41(2014), No. 6, p. 401.

S. Kongkarat, R. Khanna, P. Koshy, P. O’Kane, and V. Sahajwalla, Recycling waste polymers in EAF steelmaking: Influence of polymer composition on carbon/slag interactions, ISIJ Int., 52(2012), No. 3, p. 385.

C.M. Zhang, S.W. Chen, X.C. Miao, and H. Yuan, Reduction experiment of iron scale by adding waste plastics, J. Environ. Sci., 21(2009), Suppl. 1, p. S48.

V. Trinkel, N. Kieberger, T. Bürgler, H. Rechberger, and J. Fellner, Influence of waste plastic utilisation in blast furnace on heavy metal emissions, J. Cleaner Prod., 94(2015), p. 312.

J.M.L. Reis, R. Chianelli-Junior, J.L. Cardoso, and F.J.V. Marinho, Effect of recycled PET in the fracture mechanics of polymer mortar, Constr. Build. Mater., 25(2011), No. 6, p. 2799.

N. George and T. Kurian, Recent developments in the chemical recycling of postconsumer poly(ethylene terephthalate) waste, Ind. Eng. Chem. Res., 53(2014), No. 37, p. 14185.

J.B. Parra, C.O. Ania, A. Arenillas, F. Rubiera, J.M. Palacios, and J.J. Pis, Textural development and hydrogen adsorption of carbon materials from PET waste, J. Alloys Compd., 379(2004), No. 1-2, p. 280.

M. Pohořelý, M. Vosecký, P. Hejdová, M. Punčochář, S. Skoblja, M. Staf, J. Vošta, B. Koutský, and K. Svoboda, Gasification of coal and PET in fluidized bed reactor, Fuel, 85(2006), No. 17-18, p. 2458.

M.A.R. Dewan, G.Q. Zhang, and O. Ostrovski, Phase development in carbothermal reduction of ilmenite concentrates and synthetic rutile, ISIJ Int., 50(2010), No. 5, p. 647.

S.N. Ali, M.F. Yusop, K. Ismail, Z.A. Ghani, M.F. Abdullah, M.A.M. Ishak, and A.R. Mohamed, Tetralin-glycerol as solvent in direct liquefaction of Mukah Balingian coal, Energy Procedia, 52(2014), p. 618.

A. Yaraghi, M.H.A. Sapri, N. Baharun, S.A. Rezan, N.I. Shoparwe, S. Ramakrishnan, K.S. Ariffin, M.N.A. Fauzi, H.B. Zabidi, H. Ismail, and H.H. Seli, Aeration leaching of iron from nitrided Malaysian ilmenite reduced by polystyrene-coal reductant, Procedia Chem., 19(2016), p. 715.

S. Lashkari and B. Kruczek, Development of a fully automated soap flowmeter for micro flow measurements, Flow Meas. Instrum., 19(2008), No. 6, p. 397.

M. Sundararajan, K.H. Bhat, S. Velusamy, N. Babu, M.E.K. Janaki, S. Sasibhooshanan, and P.N. Mohan Das, Characterization of ilmenite from Kerala coastline, India: implications in the production of synthetic rutile, J. Miner. Mater. Charact. Eng., 8(2009), No. 6, p. 427.

S. Volker and K. Mario, Primary and secondary pseudobrookite minerals in volcanic rocks from the Katzenbuckel Alkaline Complex, southwestern Germany, Swiss Bull. Mineral. Petrol., 83(2003), No. 2, p. 145.

M.W. Chase Jr., NIST-JANAF Thermochemical Tables, 4th Ed., J. Phys. Chem. Ref. Data, 1998, No. 9, p. 1758.

D.G. Jones, Reaction sequences in the reduction of ilmenite: 2. Gaseous reduction by carbon monoxide, Trans. Inst. Min. Metall., 82(1973), p. C186.

Y. Zhao and F. Shadman, Kinetics and mechanism of ilmenite reduction with carbon monoxide, AIChE J., 36(1990), No. 9, p. 1433.

C.K. Ande and M.H.F. Sluiter, First-principles calculations on stabilization of iron carbides (Fe3C, Fe5C2, and η-Fe2C) in steels by common alloying elements, Metall. Mater. Trans. A, 43(2012), No. 11, p. 4436.

S. Vijayakumar and P.R. Rajakumar, Infrared spectral analysis of waste pet samples, Int. Lett. Chem. Phys. Astron., 4(2012), p. 58.

G. Socrates, Infrared and Raman Characteristic Group Frequencies: Tables and Charts, 3rd Ed., John Wiley and Sons, Ltd., Chichester, 2001, p. 15.

Z.Y. Chen, J.N. Hay, and M.J. Jenkins, The thermal analysis of poly(ethylene terephthalate) by FTIR spectroscopy, Thermochim. Acta, 552(2013), p. 123.

J. Zhang, G. Zhang, and O. Ostrovski, An experimental investigation of the gasification of graphite by carbon dioxide, Can. Metall. Q., 55(2016), No. 1, p. 104.

E. Ahmadi, S.A.R.B.S.A. Hamid, H.B. Hussin, S.R.N.B. Baharun, K.S.B. Ariffin, and M.N. Ahmad Fauzi, The preparation of iron-free TiCl4 from reduced and nitrided ilmenite by polyethylene terephthalate, INROADS Int. J. Jaipur Natl. Univ., 5(2016), No. 1, p. 11.

F.A. Halden and W.D. Kingery, Surface tension at elevated temperatures: II. Effect of C, N, O and S on liquid iron surface tension and interfacial energy with Al2O3, J. Phys. Chem., 59(1955), No. 6, p. 557.

C.J. Xuan, H. Shibata, Z. Zhao, P.G. Jönsson, and K. Nakajima, Wettability of TiN by liquid iron and steel, ISIJ Int., 55(2015), No. 8, p. 1642.

W.D. Kingery and M. Humenik Jr., Surface tension at elevated temperatures: I. Furnace and method for use of the sessile drop method; surface tension of silicon, iron and nickel, J. Phys. Chem., 57(1953), No. 3, p. 359.

Surface Energy and Thermodynamics [2016-02-10], http://www.virginia.edu/ep/SurfaceScience/Thermodynamicshtml.

R.J.D. Tilley, Understanding Solids: The Science of Materials, 2nd Ed., John Wiley & Sons Ltd., West Sussex, 2013.

Acknowledgements

The authors gratefully acknowledge the financial support from Universiti Sains Malaysia (USM) Fellowship (APEX 1002/JHEA/ATSG4001). This work was also financially supported by USM and Ministry of Higher Education (MOHE) of Malaysia through Fundamental Research Grant Scheme (FRGS) (Nos. 203/PBAHAN/6071230 and 203/PBAHAN/607126) and Research University Grant for Individual (RUI) from USM (No. 1001/PBAHAN/814273). The authors are also thankful to Dr. Hazman Haji Seli from the Faculty of Chemical Engineering, Universiti Teknologi MARA Sarawak at Kota Samarahan for providing Mukah–Balingian coal. Special thanks are given to USM technicians Mr. Shahrul and Mr. Syafiq for supporting the experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahmadi, E., Fauzi, A., Hussin, H. et al. Synthesis of titanium oxycarbonitride by carbothermal reduction and nitridation of ilmenite with recycling of polyethylene terephthalate (PET). Int J Miner Metall Mater 24, 444–454 (2017). https://doi.org/10.1007/s12613-017-1425-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1425-2