Abstract

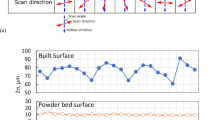

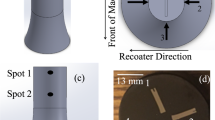

Additive manufacturing (AM) enables a fabrication freedom and is transforming the manner in which high-value and high-performance structures are created. The aerospace industry stands to benefit from structures in which the weight is minimized, the materials provide good mechanical properties at extreme temperatures, and a swarm of distinct parts can be consolidated into a single non-assembled complex structure. However, for additive manufactured parts to be used in flight-critical applications, the quality of the resulting fabricated parts must be well understood in light of the lack of flight heritage. As AM is performed layer-by-layer, new opportunities exist to monitor the fabrication in situ and non-destructively, and to provide a qualify-as-you-go paradigm. In this study, a high-resolution laser line scan profilometer is used just after a layer has been selectively melted, and the sensor is mounted to the recoater arm to provide unobtrusive and inexpensive access to the top of the powder bed. The driving hypothesis of the effort was that fused and unfused powder would lie at different elevations, as the fused powder volume would consolidate and therefore become depressed. Consequently, this measurement could both verify the intended geometry and identify any lack of fusion defects. Furthermore, some preliminary anecdotal evidence has shown that spatter can also be identified, and thus profilometry can inform the minimization of contamination (build chamber argon flow, build layout strategies, etc.).

Similar content being viewed by others

References

A.B. Spierings and G. Levy, Solid Freeform Fabrication Symposium Proceedings (2009), p. 342.

H. Meier and C. Haberland, Materialwiss. Werkstofftech. 39, 665 (2008).

D.Q. Zhang, Q.Z. Cai, J.H. Liu, and R. Di Li, Adv. Mater. Res. 97–101, 3820 (2010).

W.S. Land, B. Zhang, J. Ziegert, and A. Davies, Procedia Manuf. 1, 393 (2015).

M. Tang, P. Chris Pistorius, and J.L. Beuth, Addit. Manuf. 14, 39 (2017).

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath, and A.M. Rubenchik, J. Mater. Process. Technol. 214, 2915 (2014).

S.A. Khairallah, A.T. Anderson, A. Rubenchik, and W.E. King, Acta Mater. 108, 36 (2016).

L.E. Criales, Y.M. Arısoy, B. Lane, S. Moylan, A. Donmez, and T. Özel, Int. J. Mach. Tools Manuf. 121, 22 (2017).

R. Cunningham, S.P. Narra, C. Montgomery, J. Beuth, and A.D. Rollett, JOM 69, 479 (2017).

B.K. Foster, E.W. Reutzel, A.R. Nassar, B.T. Hall, S.W. Brown, and C.J. Dickman, in Solid Freeform Fabrication Symposium Proceedings (2015), p. 295.

S.K. Everton, M. Hirsch, P. Stravroulakis, R.K. Leach, and A.T. Clare, Mater. Des. 95, 431 (2016).

C. Barrett, J. Walker, R.E. Gutierrez, E. MacDonald, and B. Conner, in A Low Cost, High-Speed Optical Monitoring System for Tracking Spatter During Laser Powder Bed Fusion. Presented at the TMS 2018, Phoenix, AZ (2018).

T. Craeghs, F. Bechmann, S. Berumen, and J.-P. Kruth, Phys. Procedia 5B, 505 (2010).

S. Clijsters, T. Craeghs, S. Buls, K. Kempen, and J.-P. Kruth, Int. J. Adv. Manuf. Technol. 75, 108 (2014).

P. Lott, H. Schleifenbaum, W. Meiners, K. Wissenbach, C. Hinke, and J. Bültmann, Phys. Procedia 12A, 683 (2011).

I. Yadroitsev, P. Krakhmalev, and I. Yadroitsava, J. Alloys Compd. 583, 404 (2014).

M. Doubenskaia, M. Pavlov, S. Grigoriev, E. Tikhonova, and I. Smurov, J. Laser Micro Nanoeng. 7, 236 (2012).

Y. Chivel, Phys. Procedia 41, 904 (2013).

J.A. Kanko, A.P. Sibley, and J.M. Fraser, J. Mater. Process. Technol. 231, 488 (2016).

H. Krauss, C. Eschey, and M. Zaeh, in Solid Freeform Fabrication Symposium Proceedings (2012), p. 999.

B. Lane, S. Moylan, E. Whitenton, and L. Ma, Rapid Prototyp. J. 22, 778 (2016).

F. Bayle and M. Doubenskaia, Proc. SPIE 6985, 698505 (2008).

M. Grasso, V. Laguzza, Q. Semeraro, and B.M. Colosimo, J. Manuf. Sci. Eng. 139, 051001 (2017).

S. Kleszczynski, J.Z. Jacobsmühlen, J.T. Sehrt, and G. Witt, in Solid Freeform Fabrication Symposium Proceedings (2012), p. 975.

J.Z. Jacobsmühlen, S. Kleszczynski, G. Witt, and D. Merhof, in Proceedings, 30th IEEE International Instrumentation and Measurement Technology Conference, (I2MTC 2013) (2013), p. 707.

B. Zhang, J. Ziegert, F. Farahi, and A. Davies, Addit. Manuf. 12A, 100 (2016).

A. Neef, V. Seyda, D. Herzog, C. Emmelmann, M. Schönleber, and M. Kogel-Hollacher, Phys. Procedia 56, 82 (2014).

M. Islam, T. Purtonen, H. Piili, A. Salminen, and O. Nyrhilä, Phys. Procedia 41, 835 (2013).

A. Jay Dunbar, Analysis of the Laser Powder Bed Fusion Additive Manufacturing Process Through Experimental Measurement and Finite Element Modeling. Ph.D. thesis, The Pennsylvania State University. https://etda.libraries.psu.edu/catalog/28714 (2016).

B. Donaldson, Can Topography Scans Redraw the Metal Additive Inspection Map? (Additive Manuf., 2017), https://www.additivemanufacturing.media/blog/post/can-topography-scans-redraw-the-metal-additive-inspection-map/. Accessed 25 June 2018.

J. Mireles, S. Ridwan, P.A. Morton, A. Hinojos, and R.B. Wicker, Surf. Topogr. Metrol. Prop. 3, 034002 (2015).

Acknowledgements

The work was supported by the US Army Aviation Applied Technology Directorate via Grant W911W6-17-C-0048 and was made possible with the assistance and cooperation of M-7 Technologies (Youngstown).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barrett, C., MacDonald, E., Conner, B. et al. Micron-Level Layer-Wise Surface Profilometry to Detect Porosity Defects in Powder Bed Fusion of Inconel 718. JOM 70, 1844–1852 (2018). https://doi.org/10.1007/s11837-018-3025-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3025-7