Abstract

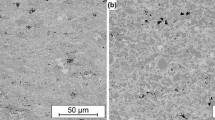

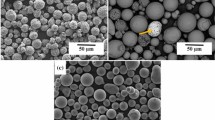

The purpose of this study is to investigate the feasibility of replacing cobalt with nickel as a binder in thermal spraying WC-based coatings. Two kinds of coatings WC-13Ni4Cr and WC-10Co4Cr were deposited by the detonation spraying technology in which propane was added into the detonation gases. The relative content of W2C and W phases in the coatings was calculated by XRD quantitative analysis method. Wear resistance of the coatings was characterized by ASTM G65 rubber-wheel abrasion test. The results indicate that the decomposition of WC particles in both coatings decreases, while the fracture toughness of the coating increases as the propane flow increases. Wear resistance of WC-based coatings is correlated with the hardness and fracture toughness of the coatings. The wear resistance of both coatings is substantially improved when increasing the propane flow rate. Experimental results show that it is feasible to replace cobalt with nickel in thermal-sprayed WC-based coatings.

Similar content being viewed by others

References

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall, Indentation Techniques for Measuring Toughness of Ceramics, J. Am. Ceram. Soc., 1981, 64, p 533

H.C. Kim, I.J. Shon, J.K. Yoon, and J.M. Doh, Comparison of Sintering Behavior and Mechanical Properties Between WC-8Co and WC-8Ni Hard Materials Produced by High-Frequency Induction Heating Sintering, Met. Mater. Int., 2006, 12, p 141-146

F. Klocke, Manufacturing Processes, in: Cutting Tool Materials and Tools, 2011 ed. (Springer, Berlin, 2011), pp. 126-133.

A.H. Dent, S. Depalo, and S. Sampath, Examination of the Wear Properties of HVOF Sprayed Nanostructured and Conventional WC-Co Cermets with Different Binder Phase Contents, J. Therm. Spray Technol., 2002, 11, p 551-558

P. Chivavibul, M. Watanabe, S. Kuroda, and K. Shinoda, Effects of Carbide Size and Co Content on the Microstructure and Mechanical Properties of HVOF-Sprayed WC-Co Coatings, Surf. Coat. Technol., 2007, 202, p 509-521

C. Verdon, A. Karimi, and J.-L. Martin, A Study of High Velocity Oxy-Fuel Thermally Sprayed Tungsten Carbide Based Coatings Part 1: Microstructures, Mater. Sci. Eng., 1998, A246, p 11-24

P. Chivavibul, M. Watanabe, and S. Kuroda, Effect of Microstructure of HVOF Sprayed WC-Co Coatings on Their Mechanical Properties, in Thermal Spray 2007: Global Coating Solutions, on CD-ROM, ed. by B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon (ASM International, Beijing, 2007), p. 1212.

V.A. Tracey, Nickel in Hardmetals, Int. J. Refract. Met. Hard Mater., 1992, 11, p 137-139

G. Bolelli, L.-M. Berger, M. Bonetti, and L. Lusvarghi, Comparative Study of the Dry Sliding Wear Behavior of HVOF-Sprayed WC-(W, Cr)2C-Ni and WC-CoCr Hardmetal Coatings, Wear, 2014, 309, p 96-111

R.C. Tucker, Plasma Spray, Detonation Gun, and HVOF Deposition Techniques, Materials and Processes for Surface and Interface Engineering, Y. Pauleau, Ed., Praxair S.T. Technology, Inc., Danbury, 1995, p 245-284

P. Suresh Babu, B. Basu, and G. Sundararajan, Processing–Structure–Property Correlation and Decarburization Phenomenon in Detonation Sprayed WC-12Co Coatings, Acta Mater., 2008, 56, p 5012-5026

H. Du, W.G. Hua, J.G. Liu, J. Gong, C. Sun, and L.S. Wen, Influence of Process Variables on the Qualities of Detonation Gun Sprayed WC-Co Coatings, Mater. Sci. Eng. A, 2005, 408, p 202-210

Q. Wang, J. Xiang, G.Y. Chen, Y.L. Cheng, X.Q. Zhao, and S.Q. Zhang, Propylene Flow, Microstructure and Performance of WC-12Co Coatings Using a Gas–Fuel HVOF Spray Process, J. Mater. Process. Technol., 2013, 213, p 1653-1660

G. Sundararajan, D. Sen, and G. Sivakumar, The Tribological Behavior of Detonation Sprayed Coatings: The Importance of Coating Process Parameters, Wear, 2005, 258, p 377-391

V. Ulianitsky, I. Batraev, D. Dudina, and I. Smurov, Enhancing the Properties of WC/Co Detonation Coatings Using Two-Component Fuels, Surf. Coat. Technol., 2017, 318, p 244-249

Y. Gao, A Set of Intermittent Detonation Sprayed Equipment (China, 2008), Patent ZL 200810076407.7.

Y. Gao, Z. Hei, X. Xu, and G. Xing, Formation of Molybdenum Boride Cermet Coating by the Detonation Spray Process, J. Therm. Spray Technol., 2001, 10, p 456-461

Y. Zhou and G.H. Wu, Analysis Methods in Materials Science X-ray Diffraction and Electron Microscopy in Materials Science, 2nd ed., Harbin Institute of Technology Press, Harbin, 2007

D. Gu, Laser Additive Manufacturing of High Performance Materials, Springer, Berlin, 2015

D.K. Shetty, I.G. Wright, and P.N. Mincer, Indentation Fracture of WC-Co Cermets, J. Mater. Sci., 1985, 20, p 1873-1882

J.M. Guilemany, J.M. de Paco, J. Nutting, and J.R. Miguel, Characterization of the W2C Phase Formed During the HVOF Spraying of WC-12Co Powder, Metall. Mater. Trans. A, 1999, 30, p 1913-1921

G. Bolelli, L.-M. Berger, T. Börne, H. Koivuluoto, L. Lusvarghi, C. Lyphout, N. Markocsan, V. Matikainen, P. Nylén, P. Sassatelli, R. Trache, and P. Vuoristo, Tribology of HVOF- and HVAF-Sprayed WC-10Co4Cr Hardmetal Coatings: A Comparative Assessment, Surf. Coat. Technol., 2015, 265, p 125-144

P. Suresh Babu, B. Basu, and G. Sundararajan, A Comparison of Mechanical and Tribological Behavior of Nano-structured and Conventional WC-12Co Detonation Sprayed Coatings, J. Therm. Spray Technol., 2013, 22, p 478-490

W. Krömmer and P. Heinrich, München, Selective Impact of Industrial Gases on the Thermal Spray Process, in Thermal Spray: Global Solutions for Future Application, International Thermal Spray Conference & Exposition (DVS Media GmbH, Düsseldorf, 2010), pp. 243-246.

J.A. Picas, E. Rupérez, M. Punset, and A. Forn, Influence of HVOF Spraying Parameters on the Corrosion Resistance of WC-CoCr Coatings in Strong Acidic Environment, Surf. Coat. Technol., 2013, 225, p 47-57

F. Habashi, Handbook of Extractive Metallurgy II, Wiley, Heidelberg, 1997

C.J. Smithells, Smithells Metals Reference Book, Butterworths, London, 1983

G.V. Samsonov, Handbooks of High-Temperature Materials Properties Index, Plenum Press, New York, 1964

Y.H. Xiong, W.H. Hofmeister, Z. Cheng, J.E. Smugeresky, E.J. Lavernia, and J.M. Schoenung, In Situ Thermal Imaging and Three-Dimensional Finite Element Modeling of Tungsten Carbide–Cobalt During Laser Deposition, Acta Mater., 2007, 57, p 5419-5429

J.G. Yang, H.B. Wang, Y. Liu, and B.Y. Huang, Diffusion Coefficient of C in Co Binder Phase, Mater. Sci. Eng. Powder Metall., 2007, 12, p 82-86

A.A. Bondar, V.A. Maslyuk, T.Ya. Velikanova, and A.V. Grytsiv, Phase Equilibria in the Cr-Ni-C System and Their Use for Developing Physicochemical Principles for Design of Hard Alloys Based on Chromium Carbide, Powder Metall. Met. Ceram., 1997, 36(5-6), p 242-252

B.H. Kear, G. Skandan, and R.K. Sadangi, Factors Controlling Decarburization in HVOF Sprayed Nano-WC/Co Hardcoatings, Scr. Mater., 2001, 44, p 1703-1707

Š. Houdková and M. Kašparová, Experimental Study of Indentation Fracture Toughness in HVOF Sprayed Hardmetal Coatings, Eng. Fract. Mech., 2013, 110, p 468-476

J. Yuan, Q. Zhan, J. Huang, S. Ding, and H. Li, Decarburization Mechanisms of WC-Co During Thermal Spraying: Insights from Controlled Carbon Loss and Microstructure Characterization, Mater. Chem. Phys., 2013, 142, p 165-171

D.A. Stewart, P.H. Shipway, and D.G. McCartney, Abrasive Wear Behavior of Conventional and Nano-composite HVOF-Sprayed WC-Co Coatings, Wear, 1999, 225, p 789-798

Y. Qiao, T.E. Fischer, and A. Dent, The Effects of Fuel Chemistry and Feedstock Powder Structure on the Mechanical and Tribological Properties of HVOF Thermal Sprayed WC-Co Coatings with Very Fines Structures, Surf. Coat. Technol., 2003, 172, p 24-41

A.C. Bozzi and J.D.B. Mello, Wear Resistance and Wear Mechanisms of WC-12Co Thermal Sprayed Coatings in Three-Body Abrasion, Wear, 1999, 233, p 575-587

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, G., Chaoqing, G., Jianyi, G. et al. Comparison of the Mechanical and Wear-Resistant Properties of WC-13Ni4Cr and WC-10Co4Cr Coatings Obtained by Detonation Spraying. J Therm Spray Tech 28, 851–861 (2019). https://doi.org/10.1007/s11666-019-00858-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00858-0