Abstract

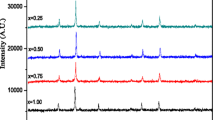

The calcium substituted nickel-zinc ferrites with the formula of CaxNi0.75−xZn0.25Fe2O4 (x = 0, 0.25, 0.5 and 0.75) have been prepared by using the chemical co-precipitation method. The X-ray diffraction (XRD) analyses reveal the results that all the samples crystallize in cubic spinel structure and the lattice constants of the samples for x = 0, 0.25, 0.50 and 0.75 are found to be 8.334, 8.348, 8.380 and 8.538 Å, respectively. The crystallite size of the samples, obtained from Debye Scherrer’s equation, varies between 12 nm and 27 nm. The scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) analyses have been conducted to reveal and determine the morphology and stoichiometry of all the prepared CaxNi0.75−xZn0.25Fe2O4 ferrite samples. The SEM images show that the partical sizes for all the samples are at nano size in accordance with the XRD results and EDX results confirm the contents of the produced samples. The dielectric and impedance properties of the prepared ferrite samples have been investigated in the frequency range from 20 Hz to 10 MHz and in the temperature range from 350 to 700 K. The real and imaginary parts of dielectric constant, tan θ, AC and DC conductivity values decrease with increasing calcium content (except x = 0). Contrary to this behavior, real and imaginary parts of impedance increase with increasing calcium content. The general AC conductivity behavior of all samples is like semiconductor behavior. The conductivity mechanism of the sample with x = 0 is explained by the mechanism of correlated barrier hopping (CBH), while it has turned into overlapping large polaron tunneling (OLPT) mechanism for all other samples. From the relaxation time graphs obtained from the impedance data, activation energies of the grain and grain boundaries are obtained. The Nyquist plots are also presented in the temperature range of 350–700 K to determine the conductivity mechanism of the prepared samples and all the plots show only one semi-circle, which means that the dominant transmission comes from the grain boundaries.

Similar content being viewed by others

References

J. Smith, H.P.J. Wijn, Ferrites, Philips Research Laboratories, N. V. Philips’ Gloeilampenfabrieken, Eindhoven (1959)

A. Goldmann, Modern Ferrite Technology, 2nd edn. (Springer, New York, 2010)

M. Hashim, A. Alimuddin, S. Kumar, B.H. Ali, H. Koo, R. Chung, J. Alloy. Compd. 511, 107–114 (2012)

A.B. Salunkhe, V.M. Khot, M.R. Phadatare, S.H. Pawar, J. Alloy. Compd. 514, 91–96 (2012)

T. Kuru, M. Kuru, S. Bağcı, J. Alloy. Compd. 753, 483–490 (2018)

T. Jahanbin, M. Hashim, K.A. Mantori, J. Magn. Magn. Mater. 322, 2684–2689 (2010)

M.A. Gabal, W.A. Bayoumy, Polyhedron 29, 2569–2573 (2010)

K. Praveena, K. Sadhana, S. Matteppanavar, H.-Lin Liu, J. Magn. Magn. Mater. 423, 343–352 (2017)

D. Paramesh, K.V. Kumar, P.V. Reddy, J. Magn. Magn. Mater. 444, 371–377 (2017)

A.N. Spaldin, M. Fiebig, Science 309, 391–392 (2005)

R.A. Mc Curie, Ferromagnetic Materials: Structure and Properties (Academic Press, London, 1994)

A.J. Baden Fuller, Ferrites at Microwave Frequencies (Peter Peregrinus, London, 1987)

H. How, M.M. Devices, J.G. Webster, Wiley Encyclopaedia of Electrical and Electronics Engineering (Wiley, New York, 1999)

H. Zheng, W. Weng, G. Han, P. Du, J. Phys. Chem. C 117, 12966–12972 (2013)

G.S. Luo, W.P. Zhou, J.D. Li, Z.Y. Zhou, G.W. Jiang, W.S. Li, S.L. Tang, Y.W. Du, J. Mater. Sci.: Mater. Electron. 28, 7259–7263 (2017)

G.S. Luo, W.P. Zhou, J.D. Li, G.W. Jiang, S.L. Tang, Y.W. Du, Trans. Nonferrous Met. Soc. China 25, 3678–3684 (2015)

A.K. Singh, T.C. Goel, R.G. Mendiratta, J. Appl. Phys. 91, 6626–6629 (2002)

H. Zhong, H.W. Zhang, J. Magn. Magn. Mater. 283, 247–250 (2004)

A.D. Sheikh, V.L. Mathe, J. Mater. Sci. 43, 2018–2025 (2008)

H.L. Ge, Z.J. Peng, C.B. Wang, Z.Q. Fu, Int. J. Mod. Phys. B 25, 3881–3892 (2011)

Z. Liu, Z. Peng, X. Fu, Ceram. Int. 43, 14938–14944 (2017)

M.N. Akhtar, A. Rahman, A.B. Sulong, M.A. Khan, Ceram. Int. 43, 4357–4365 (2017)

T. Kuru, M. Kuru, S. Bağcı, J. Mater. Sci. Mater. Electron. 29, 17160–17169 (2018)

C. Pasnicu, D. Condurache, E. Luca, Phys. Stat. Sol. 76, 145–150 (1983)

E. Rezlescu, L. Sachelarie, P.D. Popa, N. Rezlescu, IEEE Trans. Magn. 36, 3962–3967 (2010)

T. Vigneswari, P. Raji, J. Mol Struct. 1127, 515–521 (2017)

S. Singh, A. Singh, B.C. Yadav, P. Tandon, Mater. Sci. Semicond. Process. 23, 122–135 (2014)

R. Deivakumaran, G. Sathya, S.K. Suresh Babu, L. John Berchmans, J. Mater. Sci. Mater. Electron. 28, 1726–1739 (2017)

Y. Köseoğlu, E. Şentürk, V. Eyüpoğlu, T. Şaşmaz, M. Kuru, S.S. Hashim, Meena, J. Supercond. Nov. Magn. 29, 2813–2819 (2016)

P. Chavan, L.R. Naik, Vacuum 152, 47–49 (2018)

S.F. Mansour, M.A. Abdo, F.L. Kzar, J. Magn. Magn. Mater. 465, 176–185 (2018)

M. Srivastava, R.K. Mishra, J. Singh, N. Srivastava, N.H. Kim, J.H. Lee, J. Alloy. Compd. 645, 171–177 (2015)

S. Gowreesan, A. Ruban Kumar, Chin. J. Phys. 56, 1262–1272 (2018)

J. Sharma, N. Sharma, J. Parashar, V.K. Saxena, D. Bhatnagar, K.B. Sharma, J. Alloy. Compd. 649, 362–367 (2015)

T. Md, M. Rahman, C.V. Vargas, Ramana, J. Alloy. Compd. 617, 547–562 (2014)

G. Aravind, M. Raghasudha, D. Ravinder, J. Materiomics 1, 348–356 (2015)

U.R. Ghodake, N.D. Chaudhari, R.C. Kambale, J.Y. Patil, S.S. Suryavanshi, J. Magn. Magn. Mater. 407, 60–68 (2016)

I. Khorchani, O. Hafef, J.J. Reinosa, A. Matoussi, J.F. Fernandez, Mater. Chem. Phys. 212, 187–195 (2018)

T. Kuru, E. Şentürk, V. Eyüpoğlu, J. Supercond. Nov. Magn. 30, 647–655 (2017)

B. Ramesh, S. Ramesh, R. Vijaya Kumar, M. Lakshmipathi Rao, J. Alloy. Compd. 513, 289–293 (2012)

A. Azam, J. Alloy. Compd. 540, 145–153 (2012)

M.H. Dhaou, S. Hcini, A. Mallah, M.L. Bouazizi, A. Jemni, Appl. Phys. A 123, 1–9 (2017)

R.K. Panda, D. Behera, J. Alloy. Compd. 587, 481–486 (2014)

K.M. Batoo, Physica B 406, 382–387 (2011)

E. Şentürk, Y. Köseoğlu, T. Şaşmaz, F. Alan, M. Tan, J. Alloy. Compd. 578, 90–95 (2013)

M.A. Elkestawy, J. Alloy. Compd. 492, 616–620 (2010)

I. Ali, M.U. Islam, M.N. Ashiq, M.A. Iqbal, H.M. Khan, N. Karamat, J. Alloy. Compd. 579, 576–582 (2013)

R.N. Bhowmik, M.C. Aswathi, Compos. B 160, 457–470 (2019)

F.S.H. Abu-Samaha, M.I.M. Ismail, Mater. Sci. Semicond. Process. 19, 50–56 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kuru, M., Şaşmaz Kuru, T. & Bağcı, S. The role of the calcium concentration effect on the structural and dielectric properties of mixed Ni–Zn ferrites. J Mater Sci: Mater Electron 30, 5438–5453 (2019). https://doi.org/10.1007/s10854-019-00837-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00837-9