Abstract

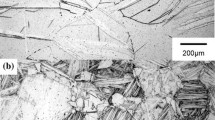

The effect of strong static magnetic field (SSMF) on the microstructure and phase transformation temperature of Co38Ni33Al29 ferromagnetic shape memory alloy during heat treatment has been studied. Results indicate that the microstructure and phase transformation temperature are significantly affected by the external SSMF. With the increasing magnetic field intensity, the volume fraction of γ phase decreased from 13.2 to 5.1%, the morphologies of γ phase evolved from rods to discrete stripes, and a clear alignment of γ phase was observed. In addition, the transformation temperatures are also elevated as the magnetic field intensity increases. The martensitic transformation temperature (MS) and the Curie point (TC) rose by 13 K and 10 K respectively when 4 T SSMF was applied. Moreover, the coercivity (HC) dramatically reduced to 11.7 Oe at 4 T magnetic field. Magnetic domains formed in β phase and they became ordered with the enhancing intensities of magnetic field.

Similar content being viewed by others

References

N.B. Morgan, Medical shape memory alloy applications-the market and its products. Mater. Sci. Eng. A 378(1), 16–23 (2004)

G. Vitel, M.G. Suru, A.L. Paraschiv et al., Structural effects of training cycles in shape memory actuators for temperature control. Mater. Manuf. Processes 28(1), 79–84 (2012)

J.M. Jani, M. Leary, A. Subic et al., A review of shape memory alloy research, applications and opportunities. Mater. Des. 56(4), 1078–1113 (2014)

Z.H. Liu, X.F. Dai, Z.Y. Zhu et al., Martensitic transformation and magnetic properties of Co-Ni-Al shape memory alloy ribbons. J. Phys. D 37(19), 2643 (2004)

S. Chatterjee, M. Thakur, S. Giri et al., Transport, magnetic and structural investigations of Co-Ni-Al shape memory alloy. J. Alloys Compd. 456(1), 96–100 (2008)

B. Bartova, D. Schryvers, Z. Yang et al., Microstructure and precipitates in as-cast Co38Ni33Al29 shape memory alloy. Scripta Mater. 57(1), 37–40 (2007)

J.B. Lu, H. Shi, S. Sedlakova-Ignacova et al., Microstructure and precipitates in annealed Co38Ni33Al29, ferromagnetic shape memory alloy. J. Alloys Compd. 572(10), 5–10 (2013)

H. Seiner, J. Kopeček, P. Sedlák et al., Microstructure, martensitic transformation and anomalies in c’-softening in Co-Ni-Al ferromagnetic shape memory alloys. Acta Mater. 61(15), 5869–5876 (2013)

G.J. Pataky, E. Ertekin, H. Sehitoglu, Elastocaloric cooling potential of NiTi, Ni2FeGa, and CoNiAl. Acta Mater. 96, 420–427 (2015)

S. Singh, R.K. Roy, B. Mahato et al., Effect of Al incorporation for Co on the gamma-beta phase boundary of rapidly solidified CoNiAl ferromagnetic shape memory alloys. J. Magn. Magn. Mater. 368(11), 379–383 (2014)

J. Ju, F. Xue, J. Zhou et al., Microstructure and mechanical properties change by rare earth Dy added in as-cast Co-Ni-Al ferromagnetic shape memory alloys. Mater. Sci. Eng. A 616, 196–200 (2014)

J. Liu, J.G. Li, Microstructure, shape memory effect and mechanical properties of rapidly solidified Co-Ni-Al magnetic shape memory alloys. Mater. Sci. Eng. A 455(16), 423–432 (2007)

J. Liu, H. Zheng, Y. Huang et al., Microstructure and magnetic field induced strain of directionally solidified ferromagnetic shape memory CoNiAl alloys. Scripta Mater. 53(1), 29–33 (2005)

R.D. Dar, H. Yan, Y. Chen, Grain boundary engineering of Co-Ni-Al, Cu-Zn-Al, and Cu-Al-Ni shape memory alloys by intergranular precipitation of a ductile solid solution phase. Scripta Mater. 115, 113–117 (2016)

K.R. Reddy, B.C. Sin, H.Y. Chi et al., A new one-step synthesis method for coating multi-walled carbon nanotubes with cuprous oxide nanoparticles. Scripta Mater. 58(11), 1010–1013 (2008)

K.R. Reddy, W. Park, B.C. Sin et al., Synthesis of electrically conductive and superparamagnetic monodispersed iron oxide-conjugated polymer composite nanoparticles by in situ chemical oxidative polymerization. J. Colloid Interface Sci. 335(1), 34–39 (2009)

Y.P. Zhang, S.H. Lee, K.R. Reddy et al., Synthesis and characterization of core-shell SiO2 nanoparticles/poly(3-aminophenylboronic acid) composites. J. Appl. Polym. Sci. 104(4), 2743–2750 (2007)

K.R. Reddy, K.P. Lee, A.I. Gopalan, Self-assembly approach for the synthesis of electro-magnetic functionalized Fe3O4/polyaniline nanocomposites: effect of dopant on the properties. Colloids Surf. A 320(1–3), 49–56 (2008)

K.R. Reddy, V.G. Gomes, M. Hassan, Carbon functionalized TiO2 nanofibers for high efficiency photo catalysis. Mater. Res. Express 1(1), 015012 (2014)

K.R. Reddy, M. Hassan, V.G. Gomes, Hybrid nanostructures based on titanium dioxide for enhanced photo catalysis. Appl. Catal. A 489, 1–16 (2015)

K. Liu, P. Bai, M.Z. Bazant et al., A soft non-porous separator and its effectiveness in stabilizing Li metal anodes cycling at 10 mA cm−2 observed in situ in a capillary cell. J. Mater. Chem. A 5(9), 4300–4307 (2017)

R.L. Yu, S.C. Kim, H.I. Lee et al., Graphite oxides as effective fire retardants of epoxy resin. Macromol. Res. 19(1), 66–71 (2011)

J. Zhu, X. Zhu, Z. Zhang et al., Reversible addition-fragmentation chain transfer polymerization of styrene under microwave irradiation. J. Polym. Sci. A 44(23), 6810–6816 (2006)

A.M. Showkat, Y.P. Zhang, S.K. Min et al., Analysis of heavy metal toxic ions by adsorption onto amino-functionalized ordered mesoporous silica. Bull. Korean Chem. Soc. 28(11), 1985–1992 (2007)

X. Li, Y. Fautrelle, A. Gagnoud et al., Effect of a weak transverse magnetic field on solidification structure during directional solidification. Acta Mater. 64(2), 367–381 (2014)

H. Li et al., Effect of a transverse magnetic field on solidification structure in directionally solidified Al-40 wt.% Cu alloys. J. Mater. Res. 31(2), 213–221 (2016)

J. Wang, Y. He, J. Li et al., Strong magnetic field effect on the nucleation of a highly undercooled Co-Sn melt. Sci. Rep. 7(1), 4958 (2017)

J. Wang, Y. Sheng, Y. Fautrelle et al., Refinement and growth enhancement of Al2Cu phase during magnetic field assisting directional solidification of hypereutectic Al-Cu alloy. Sci. Rep. (2016). https://doi.org/10.1038/srep24585

J. Wang, Y. He, J. Li et al., Reexaminations of the effects of magnetic field on the nucleation of undercooled Cu melt. Jpn. J. Appl. Phys. 55(10), 105601 (2016)

J. Wang, J. Li, H. Kou et al., Instability pattern formation in a liquid metal under high magnetic fields. Sci. Rep. 7(1), 2248 (2017)

Y.Y. Gong et al., Textured, dense and giant magnetostrictive alloy from fissile polycrystalline. Acta Mater. 98, 113–118 (2015)

Q. Wang, T. Liu, K. Wang et al., Progress on high magnetic field-controlled transport phenomena and their effects on solidification microstructure. ISIJ Int. 54(3), 516–525 (2014)

X. Li, A. Gagnoud, Z. Ren et al., Investigation of thermoelectric magnetic convection and its effect on solidification structure during directional solidification under a low axial magnetic field. Acta Mater. 57(7), 2180–2197 (2009)

X. Li, Y. Fautrelle, Z. Ren, Influence of an axial high magnetic field on the liquid–solid transformation in Al-Cu hypoeutectic alloys and on the microstructure of the solid. Acta Mater. 55(4), 1377–1386 (2007)

X. Li, Y. Fautrelle, Z. Ren, Influence of a high magnetic field on columnar dendrite growth during directional solidification. Acta Mater. 55(16), 5333–5347 (2007)

T.P. Hou, Y. Li, K.M. Wu, Effect of high magnetic field on alloy carbide precipitation in a Fe-C-Mo alloy. J. Alloys Compd. 527(12), 240–246 (2012)

P. Yang, Y. Liu, X. Zhao et al., Electromagnetic wave absorption properties for FeCoNiCr alloy powders with magnetic field heat treatment. J. Mater. Sci.: Mater. Electron. 28(13), 1–9 (2017)

C. Li, G. Guo, Z. Yuan et al., Chemical segregation and coarsening of γ′ precipitates in Ni-based superalloy during heat treatment in alternating magnetic field. J. Alloys Compd. 720, 272–276 (2017)

Y. Yuan, Q. Wang, K. Iwai et al., Isothermal heat treatments of an Al-4.8 mass% Cu alloy under high magnetic fields. J. Alloys Compd. 560(4), 127–131 (2013)

X. Li, X. Bao, Y. Liu et al., Tailoring magnetostriction with various directions for directional solidification Fe82Ga15Al3 alloy by magnetic field heat treatment. Appl. Phys. Lett. 111(16), 162402 (2017)

K. Wang, Q. Wang, C. Wang et al., Formation of aligned two-phase microstructure in Fe-0.25 mass% C alloy under gradient high magnetic fields. Mater. Lett. 62(10), 1466–1468 (2008)

K. Ishida, R. Kainuma, N. Ueno et al., Ductility enhancement in NiAl (B2)-base alloys by microstructural control. Metall. Trans. A 22(2), 441–446 (1991)

R. Kainuma, M. Ise, C.C. Jia et al., Phase equilibria and microstructural control in the Ni-Co-Al system. Intermetallics 4(8), S151–S158 (1996)

H. Morito, A. Fujita, K. Fukamichi et al., Magnetocrystalline anisotropy in single-crystal Co-Ni-Al ferromagnetic shape-memory alloy. Appl. Phys. Lett. 81(9), 1657–1659 (2002)

J. Wang, Y.X. He, J.S. Li et al., Experimental platform for solidification and in-situ magnetization measurement of undercooled melt under strong magnetic field. Rev. Sci. Instrum. 86(2), 025102 (2015)

R. Khan, M.U. Rahman, Z.U. Rahman et al., Effect of air annealing on the structure, dielectric and magnetic properties of (Co, Ni) co-doped SnO2, nanoparticles. J. Mater. Sci.: Mater. Electron. 27(10), 10532–10540 (2016)

I.V. Gervasyeva, E. Beaugnon, V.A. Milyutin et al., Formation of structure and crystallographic texture in Fe-50% Ni thin tapes under high magnetic field annealing. Phys. B 468–469, 66–71 (2015)

N. Zhang, G. Li, X. Wang et al., The influence of annealing temperature on hyperfine magnetic field and saturation magnetization of Fe-Si-Al-Cr flake-shaped particles. J. Alloys Compd. 672, 176–181 (2016)

J. Kopeček, V. Kopecký, M. Landa et al., Structural changes in Co-based F-SMA. Mater. Sci. Forum 739, 416–420 (2013)

L. Song, G.F. Wang, Z.Q. Ou et al., Magnetic properties and magnetocaloric effect of MnFeP0.5Ge0.5−xSix, compounds. J. Alloys Compd. 474(1–2), 388–390 (2009)

Acknowledgements

Authors acknowledge the financial support from the Natural Science Foundation of China (No. 51690163) and the Program of Introducing Talents of Discipline to Universities (No. B08040).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bu, F., Xue, X., Wang, J. et al. Effect of strong static magnetic field on the microstructure and transformation temperature of Co–Ni–Al ferromagnetic shape memory alloy. J Mater Sci: Mater Electron 29, 19491–19498 (2018). https://doi.org/10.1007/s10854-018-0079-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0079-9