Abstract

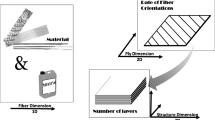

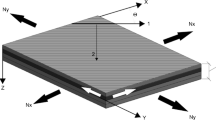

The design process of laminated composites faces two challenges: the engineer designs the product and its morphology, but also, simultaneously, the material. The number of design solutions can be huge since the solution space is very large. Standard CAE systems (CAD, Finite Element Simulation) do not offer to the designer an approach to explore these solution spaces efficiently and interactively. This paper provides a possible procedure for engineers having a laminated composite product to create: it presents an approach that allows combining to usual morphological design parameters, specific variables that are typically the domain of composite experts, and manufacturing experts. Using an optimization approach based on an evolutionary algorithm coupled to a reduced order analysis, a decision support solution is detailed. The numerical approach allows the engineer to explore interactively design spaces. Our approach is consisting in processing a Knowledge Model having a reduced and separated form [9]. We present a decision support method that allow designers to have, both, a multiscale and a multiphysical view on the laminated structures that they are creating. Two design problems are presented to illustrate the relevance of the approach when designing composite structures: one under a static load and the having a dynamic behavior.

Similar content being viewed by others

Abbreviations

- E :

-

Young’s modulus (MPa)

- E f :

-

Fiber Young’s modulus (MPa)

- E m :

-

Matrix Young’s modulus (MPa)

- E l :

-

Young’s modulus of the ply in the direction of the fibers (MPa)

- E t :

-

Young’s modulus of the ply in a direction transversal to the fiber direction (MPa)

- F y ,F z :

-

External forces (N)

- F(ω) :

-

Force as a function of frequency (N)

- B :

-

Body force

- G :

-

Shear modulus (MPa)

- v :

-

Poisson’s ratio

- l :

-

Length (mm)

- h :

-

Height (mm)

- w :

-

Width (mm)

- u :

-

Displacement in direction x

- v :

-

Displacement in direction y

- w :

-

Displacement in direction z

- ε :

-

Strain tensor

- σ :

-

Stress Tensor (Pa)

- σ ij :

-

Stress tensor element (Pa)

- F 0 :

-

Objective function

- ς, ξ, ψ :

-

(Weights)

- \( {\mathbf{\mathcal{L}}}_{\boldsymbol{max}} \) :

-

Maximum deformation to the direction y

- \( {\boldsymbol{U}}_{\boldsymbol{x},\boldsymbol{y},\boldsymbol{z},{\boldsymbol{p}}_{\mathbf{1}},{\boldsymbol{p}}_{\mathbf{2}},\bullet \bullet \bullet, {\boldsymbol{p}}_{\boldsymbol{d}}} \) :

-

Approximation of displacement field (mm)

- U(x, y, z, p 1, p 1, ⋯, p d) :

-

Displacement field as a function of given parameters (mm)

- C :

-

Tensor of material properties in local coordinates

- n :

-

Number of enrichment modes in PGD sense

- \( \overline{\boldsymbol{C}} \) :

-

Tensor of material properties in global coordinates

- \( \overline{\boldsymbol{C}}\left({\boldsymbol{p}}_{\mathbf{1}}\right),\overline{\boldsymbol{C}}\left({\boldsymbol{p}}_{\mathbf{2}}\right),\overline{\boldsymbol{C}}\left({\boldsymbol{p}}_{\mathbf{3}}\right),\overline{\boldsymbol{C}}\left({\boldsymbol{p}}_{\mathbf{4}}\right) \) :

-

Tensor of material properties at plies 1, 2, 3, 4 in global coordinates

- C int :

-

Tensor of material properties at the interfaces

- D :

-

Transformation matrix

- ρ :

-

Density (kg/m3)

- ρ f :

-

Fiber density

- ρ m :

-

Resin density

- Ω :

-

Geometric domain

- θ i :

-

Fiber orientation of ply i (degrees)

- V f :

-

Fiber volume fraction (%)

- G 0 :

-

Short term shear modulus (GPa)

- G ∞ :

-

Long-term shear modulus (GPa)

- α :

-

Fractional derivative order

- τ :

-

Decay time (s)

- X, Y, Z, P1, P2, P3, P4, P5, P6, P7 :

-

PGD functions

- x,y,z,p 1 ,p 2 ,p 3 ,p 4 ,p 5 ,p 6 ,p 7 :

-

PGD domains

- T max :

-

Maximum twist

References

Almeida, J.H.S., Ribeiro, M.L., Tita, V., Amico, S.C.: Stacking sequence optimization in composite tubes under internal pressure based on genetic algorithm accounting for progressive damage. Compos. Struct. 178, 20–26 (2017). https://doi.org/10.1016/j.compstruct.2017.07.054

Bouyssou D. Ed: Decision-making process: concepts and methods. ISTE [u.a.], London (2009)

Calado, E.A., Leite, M., Silva, A.: Selecting composite materials considering cost and environmental impact in the early phases of aircraft structure design. J. Clean. Prod. 186, 113–122 (2018). https://doi.org/10.1016/j.jclepro.2018.02.048

Carrera, E.: Theories and finite elements for multilayered, anisotropic, composite plates and shells. Arch. Comput. Methods Eng. 9, 87–140 (2002). https://doi.org/10.1007/BF02736649

Corona, A., Madsen, B., Hauschild, M.Z., Birkved, M.: Natural fibre selection for composite eco-design. CIRP Ann. 65, 13–16 (2016). https://doi.org/10.1016/j.cirp.2016.04.032

Coronado Mondragon, A.E., Coronado Mondragon, C.E., Hogg, P.J., Rodríguez-López, N.: A design process for the adoption of composite materials and supply chain reconfiguration supported by a software tool. Comput. Ind. Eng. 121, 62–72 (2018). https://doi.org/10.1016/j.cie.2018.05.022

Dutra, T.A., de Almeida, S.F.M.: Composite plate stiffness multicriteria optimization using lamination parameters. Compos. Struct. 133, 166–177 (2015). https://doi.org/10.1016/j.compstruct.2015.07.029

Fischer, X., Nadeau, J.-P., Sébastian, P., Joyot, P.: Decision support in integrated mechanical design through qualitative constraints. In: Integrated Design and Manufacturing in Mechanical Engineering, pp. 35–42 (2002)

Fontecha Dulcey, G., Fischer, X., Joyot, P., Fadel, G.: Support for decision making in Design of Composite Laminated Structures; part 1: parametric knowledge model., applied composite materials, springer. Nature. (2018)

Gascons, M., Blanco, N., Mayugo, J.A., Matthys, K.: A strategy to support design processes for fibre reinforced thermoset composite materials. Appl. Compos. Mater. 19, 297–314 (2012). https://doi.org/10.1007/s10443-011-9203-1

Hambali, A., Sapuan, S.M., Ismail, N., Nukman, Y.: Material selection of polymeric composite automotive bumper beam using analytical hierarchy process. J. Cent. S. Univ. Technol. 17, 244–256 (2010). https://doi.org/10.1007/s11771-010-0038-y

Irisarri, F.-X., Bassir, D.H., Carrere, N., Maire, J.-F.: Multiobjective stacking sequence optimization for laminated composite structures. Compos. Sci. Technol. 69, 983–990 (2009). https://doi.org/10.1016/j.compscitech.2009.01.011

Kamiński, M.M.: Computational Mechanics of Composite Materials: Sensitivity, Randomness, and Multiscale Behaviour. Springer, London (2005)

Kwon, Y.W., Allen, D.H., Talreja, R.: Multiscale modeling and simulation of composite materials and structures. Springer, New York (2008)

Macquart, T., Maes, V., Bordogna, M.T., Pirrera, A., Weaver, P.M.: Optimisation of composite structures – enforcing the feasibility of lamination parameter constraints with computationally-efficient maps. Compos. Struct. 192, 605–615 (2018). https://doi.org/10.1016/j.compstruct.2018.03.049

Mejia Gutierrez, R., Fischer, X., Bennis, F.: A tutor agent for supporting distributed knowledge modelling in interactive product design. Int. J. Intell. Syst. Technol. Appl. 4, 399 (2008). https://doi.org/10.1504/IJISTA.2008.017281

Michalewicz Z.: Genetic algorithms + data structures = evolution programs. Springer-Verlag, Berlin; New York (1994)

Nikbakt, S., Kamarian, S., Shakeri, M.: A review on optimization of composite structures part I: laminated composites. Compos. Struct. 195, 158–185 (2018). https://doi.org/10.1016/j.compstruct.2018.03.063

Pahl, G., Wallace, K., Blessing, L., Pahl, G. (eds.): Engineering design: a systematic approach. Springer, London (2007)

Reddy, J.N.: An evaluation of equivalent-single-layer and layerwise theories of composite laminates. Compos. Struct. 25, 21–35 (1993). https://doi.org/10.1016/0263-8223(93)90147-I

Sanz-Corretge, J.: A procedure to design optimum composite plates using implicit decision trees. Struct. Multidiscip. Optim. 56, 1169–1183 (2017). https://doi.org/10.1007/s00158-017-1711-7

Srinivasan, R., Karandikar, H.M., Mistree, F.: Understanding design-manufacture interaction using compromise decision support problems—III. Design for manufacture of composite pressure vessels. Comput. Struct. 40, 705–717 (1991). https://doi.org/10.1016/0045-7949(91)90238-H

Acknowledgements

The research was supported by the Colciencias (Colombia) and the Universidad Pontificia Bolivariana (Bucaramanga, Colombia).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fontecha Dulcey, G., Fischer, X., Joyot, P. et al. Support for Decision Making in Design of Composite Laminated Structures. Part 2: Reduced Parametric Model-Based Optimization. Appl Compos Mater 26, 663–681 (2019). https://doi.org/10.1007/s10443-018-9742-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-018-9742-9