Abstract

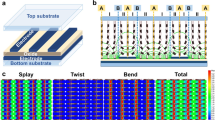

Patterning and aligning are the most distinctive research areas in surface science. In this paper, we demonstrate a fabrication method for the simultaneous formation of a wall-structured surface relief and a molecular aligning region between the walls. A photoreactive polymer, poly(vinyl cinnamate) (PVCi), was used as the matrix; it was coated either onto a rigid glass substrate or a flexible plastic substrate. We used a solvent-assisted micro-molding poly(dimethylsiloxane) stamp to form 10-μm-wide and 10-μm-high walls every 100 μm on the matrix. The direction of the molecular alignment in the region between the walls was perpendicular to the direction of the walls; this finding was confirmed by the subsequent liquid crystal (LC) alignment investigation. The alignment of this wide region between the wall structures is uncommon and differs from the molecular alignment induced by the microgroove topology due to the patterning. Additionally, the application of linearly polarized ultraviolet irradiation onto the photoreactive PVCi improved the molecular alignment either on the region between the walls or on the lateral side of the walls; this finding was confirmed by polarized light microscopy imaging. The simultaneous formation of the wall support in the molecular aligning region can be used in flexible LC displays, in which the maintenance of cell gaps and the aligning of the LC material play a critical role in display performance.

Similar content being viewed by others

References

J. Jang, Mater. Today, 9, 46 (2006).

S. J. Sung, E. A. Jung, D. H. Kim, D. H. Son, J. K. Kang, and K. Y. Cho, Opt. Express, 18, 11737 (2010).

Y. T. Kim, J. H. Hong, T. Y. Yoon, and S. D. Lee, Appl. Phys. Lett., 88, 263501 (2006).

V. Vorflusev and S. Kumar, Science, 283, 1903 (1999).

H. Hah, S. J. Sung, M. Han, S. S. Lee, and J. K. Park, Displays, 29, 478 (2008).

Y. Kim, J. Francl, B. Taheri, and J. L. West, Appl. Phys. Lett., 72, 2253 (1998).

S. J. Jang, J. H. Kim, J. H. Bae, Y. Choi, H. R. Kim, S. I. Kim, J. H. Souk, and J. H. Kim, Mol. Cryst. Liq. Cryst., 470, 191 (2007).

A. Hellemans, IEEE Spectr., 37, 18 (2000).

T. Scharf, A. Shlayen, C. Gernez, N. Basturk, and J. Grupp, Mol. Cryst. Liq. Cryst., 412, 135 (2004).

H. Hah, S. J. Sung, M. Han, S. Lee, and J. K. Park, Mater. Sci. Eng. C, 27, 798 (2007).

H. Vithana, D. Johnson, and P. Bos, Jpn. J. Appl. Phys., 35, L320 (1996).

M. Schadt, K. Schmitt, V. Kozinkov, and V. Chigrinov, Jpn. J. Appl. Phys., 31, 2155 (1992).

M. Schadt, H. Seiberle, and A. Schuster, Nature, 381, 212 (1996).

K. Ichimura, Y. Akita, H. Akiyama, K. Kudo, and Y. Hayashi, Macromolecules, 30, 903 (1997).

S. J. Sung, D. H. Kim, M. R. Kim, and K. Y. Cho, Macromol. Res., 18, 614 (2010).

J. Lee, S. Lee, Y. C. Jeong, K. Y. Cho, and J. K. Park, Opt. Express, 17, 23565 (2009).

S. J. Sung, J. H. Yun, S. Lee, J. K. Park, D. H. Kim, and K. Y. Cho, React. Funct. Polym., 70, 622 (2010).

T. C. Lin, S. C. Yu, P. S. Chen, K. Y. Chi, H. C. Pan, and C. Y. Chao, Curr. Appl. Phys., 9, 610, (2009).

H. Hah, S. J. Sung, and J. K. Park, Appl. Phys. Lett., 90, 063508 (2007).

J. S. Choi, K. Y. Cho, and J. H. Yim, Eur. Polym. J., 46, 389 (2010).

N. Y. Lee, J. R. Lim, M. J. Lee, J. B. Kim, S. J. Jo, H. K. Baik, and Y. S. Kim, Langmuir, 22, 9018 (2006).

J. A. Rogers, Z. N. Bao, and L. Dhar, Appl. Phys. Lett., 73, 294 (1998).

J. Hahm and S. J. Sibener, Langmuir, 16, 4766 (2000).

M. Kimura, M. J. Misner, T. Xu, S. H. Kim, and T. P. Russell, Langmuir, 19, 9910 (2003).

S. H. Kim, M. J. Misner, T. Xu, M. Kimura, and T. P. Russell, Adv. Mater., 16, 226 (2004).

J. Naciri, J. Y. Fang, M. Moore, D. Shenoy, C. S. Dulcey, and R. Shashidar, Chem. Mater., 12, 3288 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yun, J.H., Sung, SJ. & Cho, K.Y. Simultaneous fabrication of an alignment layer and a wall structure for a liquid crystal display by solvent-assisted micromolding. Macromol. Res. 20, 453–458 (2012). https://doi.org/10.1007/s13233-012-0065-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-012-0065-7