Abstract

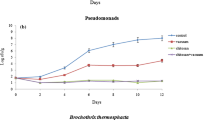

Modified atmosphere packaging (MAP) studies on microbiological and sensory analysis were conducted to extend the shelf life of ready-to-bake pizza stored at 7±1°C. The gas combinations used were: atm1: air (control), atm2: CO2 (100%), atm3: N2 (100%), atm4: 50% CO2/50% N2. Total plate count (TPC), yeasts/molds (Y/M), coliforms, lactic acid bacteria (LAB), psychrotrophs, and anaerobic spore formers were estimated at time intervals of 0, 5, 10, 15, and 20 days. TPC and LAB of pizza samples (atm1) reached 7.10 and 8.14 log CFU/g after 10 days of storage, respectively. Coliforms, psychrotrophs, and Y/M were significantly higher (p<0.05) for pizza samples stored in atm1 than other storage conditions of MAP. Finally, counts of anaerobic spore formers were low (<3 log CFU/g) irrespective of the packaging conditions throughout the entire storage period. It was concluded that among the 4 atmospheres examined, atm2 (100% CO2) was the best, followed by atm4>atm3>atm1 respectively, in descending order. MAP conditions under this study may extend shelf life of pizza to considerable amount of time.

Similar content being viewed by others

References

Pfeiffer C, D’Aujourd’hui M, Walter J, Nuessli J, Escher F. Optimising food packaging of bakery products. Food Technol.-Chicago 53: 52–58 (1999)

Kohn S. An update of the US baking industry. Cereal Foods World 45: 94–97 (2000)

McMillin KW. Where is MAP going? A review and future potential of modified atmosphere packaging for meat. Meat Sci. 80: 43–65 (2008)

Singh P, Goyal GK, Wani AA. Effects of modified atmosphere packaging and refrigerated storage on the sensory characteristics of ready-to-serve pizza. Milchwissenschaft 65: 306–309 (2010)

Brackett RE. Pathogenic microorganisms associated with fresh produce. J. Food Protect. 53: 391–395 (1996)

Alam T. Studies on the modified atmosphere packaging of mozzarella cheese. PhD thesis, National Dairy Research Institute (NDRI) Deemed University, Karnal, India (2004)

Day BPF. Guidelines for the good manufacturing and handling of modified atmosphere packed food products. Technical Manual No. 34. The Campden Food and Drink Research Association, Chipping Campden, UK (1992)

Labuza TP, Schmidl MK. Accelerated shelf life testing of foods. Food Technol.-Chicago 9: 57–62, 64, 134 (1985)

APHA. Compendium of methods for the microbiological examination of foods, 3rd ed. American Public Health Association, Washington, DC, USA (1992)

Rao KVSS. A process for manufacture of paneer like product. PhD thesis, National Dairy Research Institute (NDRI) Deemed University, Karnal, India (1991)

Winger RJ, Pope CG. Selection and training of panellists for sensory evaluation of meat flavours. Int. J. Technol. 16: 661–669 (1976)

Cabo ML, Pastoriza L, Bernardez M, Herrera JJR. Effectiveness of CO2 and nisaplin on increasing shelf life of fresh pizza. Food Microbiol. 18: 489–498 (2001)

Anonymous. Statistical Package for Social Sciences. SPSS Inc., Chicago, IL, USA. (www.spss.com) (2008)

Kamel B, Manji B. Effect of frozen storage on different pizza formulations. Cereal Foods World 31: 751–755 (1986)

Fasano L, Gallo C. Pizza-bases with tomato packaged with modified atmosphere: Environment monitoring and shelf life studies. Ind. Aliment.-Italy 11: 1039–1044 (2001)

Donnelly CW. Detection and isolation of Listeria monocytogenes from food samples: Implications of sublethal injury. J. AOAC Int. 85: 495–500 (2002)

CFS (Centre for Food Safety). Microbiological Guidelines for Ready-to-eat Foods. Risk Assessment Section, Centre for Food Safety, Food and Environmental Hygiene Department, Hongkong. pp. 1–15 (2007)

Scott CR, Smith HO. Cottage cheese shelf life and special gas atmospheres. J. Food Sci. 36: 78–80 (1971)

Alves MVR, Sarantopoulos CIGDL, Van Dender AGF, Faria JDAF. Stability of sliced mozzarella cheese in modified atmosphere packaging. J. Food Protect. 59: 838–844 (1996)

Fedio WM, Macleod A, Ozimek L. The effect of modified atmosphere packaging on the growth of microorganisms in cottage cheese. Milchwissenschaft 49: 622–629 (1994)

Eliot SC, Vuillemard JC, Emond JP. Stability of shredded mozzarella cheese under modified atmosphere packaging. J. Food Sci. 63: 1075–1080 (1998)

Enfors SO, Molin G. The Influence of high concentrations of CO2 on the germination of bacterial spores. J. Appl. Bacteriol. 45: 279–285 (1978)

Holzapfel WH. The Gram-negative bacteria associated with meat and meat products. pp. 35–84. In: Microbiology of Meat and Poultry. Davis A, Board R (eds). Blackie Academic and Professional, London, England (1998)

Chen JH, Hotchkiss JH. Effect of dissolved CO2 on the growth of psychrotrophic organisms in cottage cheese. J. Dairy Sci. 74: 2941–2945 (1991)

Villari P, Costabile P, Fasanaro G, DiSio F, Laratta B, Pirone G, Castaldo D. Quality loss of double concentrated tomato paste: Evolution of the microbial flora and main analytical parameters during storage at different temperatures. J. Food Process. Pres. 18: 369–387 (1994)

Nissen H, Rosnes JT, Brendehaug J, Kleiberg GH. Safety evaluation of sous vide-processed ready meals. Lett. Appl. Microbiol. 35: 433–438 (2002)

Farber JM. Microbiological aspects of modified atmospherepackaging technology: A review. J. Food Protect. 54: 58–70 (1991)

Smoot LA, Pierson MD. Inhibition and control of bacterial spore germination. J. Food Protect. 45: 84–92 (1982)

Ingram M. Microbiological principles in prepackaging meats. J. Appl. Bacteriol. 25: 259–262 (1963)

Sharpe ME. Lactobacilli in meat products. Food Manuf. 37: 582–589 (1962)

Maniar B, Marcy AJE, Bishop JR, Duncan SE. Modified atmosphere packaging to maintain direct set cottage cheese quality. J. Food Sci. 59: 1305–1308, 1327 (1994)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, P., Wani, A.A. & Goyal, G.K. Quality of chilled ready-to-bake pizza stored in air and under modified atmospheres: Microbiological and sensory attributes. Food Sci Biotechnol 20, 1–6 (2011). https://doi.org/10.1007/s10068-011-0001-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-011-0001-1