Abstract

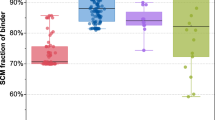

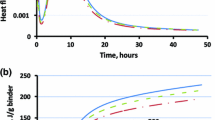

Alkali-activated slag concretes stored for 7 years under atmospheric conditions are assessed, and the structural characteristics of naturally carbonated regions are determined. Concretes formulated with a 400 kg/m3 and water/binder (w/b) ratio between 0.42 and 0.48 present similar natural carbonation depths, although these concretes report different permeabilities after 28 days of curing. The inclusion of increased contents of binder leads to a substantial reduction of the CO2 penetration in these concretes, so that negligible carbonation depth values (2 mm) are identified in concretes formulated with 500 kg/m3 of binder. Calcite, vaterite, and natron are identified as the main carbonation products formed in these concretes. These observations differ from the trends which would be expected in comparable ordinary Portland cement-based concretes, which is attributable to the physical (permeability) and chemical properties of alkali-activated slag concretes promoting high long-term stability and acceptably slow carbonation progress under natural atmospheric conditions.

Similar content being viewed by others

References

Juenger MCG, Winnefeld F, Provis JL, Ideker JH (2011) Advances in alternative cementitious binders. Cem Concr Res 41(12):1232–1243

van Deventer JSJ, Provis JL, Duxson P (2012) Technical and commercial progress in the adoption of geopolymer cement. Miner Eng 29:89–104

Wang S-D, Pu X-C, Scrivener KL, Pratt PL (1995) Alkali-activated slag cement and concrete: a review of properties and problems. Adv Cem Res 7(27):93–102

Talling B, Krivenko PV (1997) Blast furnace slag: the ultimate binder. In: Chandra S (ed) Waste materials used in concrete manufacturing. Noyes Publications, Park Ridge, pp 235–289

Roy D (1999) Alkali-activated cements: opportunities and challenges. Cem Concr Res 29(2):249–254

Shi C, Krivenko PV, Roy DM (2006) Alkali-activated cements and concretes. Taylor & Francis, Abingdon

van Deventer JSJ, Provis JL, Duxson P, Brice DG (2010) Chemical research and climate change as drivers in the commercial adoption of alkali activated materials. Waste Biomass Valoriz 1(1):145–155

Puertas F, Palacios M, Vázquez T (2006) Carbonation process of alkali-activated slag mortars. J Mater Sci 41:3071–3082

Palacios M, Puertas F (2006) Effect of carbonation on alkali-activated slag paste. J Am Ceram Soc 89(10):3211–3221

Bernal SA, Mejía de Gutierrez R, Rose V, Provis JL (2010) Effect of silicate modulus and metakaolin incorporation on the carbonation of alkali silicate-activated slags. Cem Concr Res 40(6):898–907

Bernal SA, Mejía de Gutierrez R, Pedraza AL, Provis JL, Rodríguez ED, Delvasto S (2011) Effect of binder content on the performance of alkali-activated slag concretes. Cem Concr Res 41(1):1–8

Papadakis VG, Vayenas CG, Fardis MN (1991) Experimental investigation and mathematical modeling of the concrete carbonation problem. Chem Eng Sci 46:1333–1338

Hobbs DW (2001) Concrete deterioration: causes, diagnosis, and minimising risk. Int Mater Rev 46(3):117–144

Johannesson B, Utgenannt P (2001) Microstructural changes caused by carbonation of cement mortar. Cem Concr Res 31:925–931

Steffens A (2002) Modeling carbonation for corrosion risk prediction of concrete structures. Cem Concr Res 32:938–941

Glasser FP, Marchand J, Samson E (2008) Durability of concrete: degradation phenomena involving detrimental chemical reactions. Cem Concr Res 38(2):226–246

Poonguzhali A, Shaikh H, Dayal RK, Khatak HS (2008) Degradation mechanism and life estimation of civil structures: a review. Corros Rev 26(4):215–294

Deja J (2002) Carbonation aspects of alkali activated slag mortars and concretes. Silic Ind 67(1):37–42

Xu H, Provis JL, van Deventer JSJ, Krivenko PV (2008) Characterization of aged slag concretes. ACI Mater J 105(2):131–139

Bernal SA, Mejía de Gutierrez R, Provis JL (2012) Carbonation of alkali-activated GBFS-MK concretes. In: Justnes H, Jacobsen S, Cepuritis R, Hornbostel K, Peng Y (eds) International congress on durability of concrete. CD-ROM, Norsk Betongforening, Trondheim

Bernal SA, Provis JL, Brice DG, Kilcullen A, Duxson P, van Deventer JSJ (2012) Accelerated carbonation testing of alkali-activated binders significantly underestimate the real service life: the role of the pore solution. Cem Concr Res 42(10):1317–1326

Hewlett PC (1998) Lea’s chemistry of cement and concrete, 4th edn. Elsevier, Oxford

Ho DWS, Lewis RK (1987) Carbonation of concrete and its prediction. Cem Concr Res 17(3):489–504

Lloyd RR, Provis JL, van Deventer JSJ (2010) Pore solution composition and alkali diffusion in inorganic polymer cement. Cem Concr Res 40(9):1386–1392

Greenwood K, Pearce M (1953) The removal of carbon dioxide from atmospheric air by scrubbing with caustic soda in packed towers. Trans Inst Chem Eng 31:201–207

Bernal SA, Provis JL, Mejía de Gutierrez R, Rose V (2011) Evolution of binder structure in sodium silicate-activated slag-metakaolin blends. Cem Concr Compos 33(1):46–54

Melo Neto AA, Cincotto MA, Repette W (2008) Drying and autogenous shrinkage of pastes and mortars with activated slag cement. Cem Concr Res 38:565–574

de Castro A, Ferreira R, Lopes AM, Cascudo O, Carasek H (2004) Relationship between results of accelerated and natural carbonation in various concretes. In: Vázquez E, Hendriks CF, Janssen GMT (eds) International RILEM Conference on the use of recycled materials in building and structures. RILEM Publications, Barcelona, pp 988–997

Bernal SA, Provis JL, Walkley B, San Nicolas R, Gehman JD, Brice DG, Kilcullen AR, Duxson P, van Deventer JSJ (2013) Gel nanostructure in alkali-activated binders based on slag and fly ash, and effects of accelerated carbonation. Cem Concr Res (Submitted)

Bernal SA, Provis JL, Rose V, Mejía de Gutiérrez R (2013) High-resolution X-ray diffraction and fluorescence microscopy characterization of alkali-activated slag-metakaolin binders. J Am Ceram Soc. doi:10.1111/jace.12247

Albert BR, Cheetham AK (2000) A synchrotron X-ray powder diffraction study of highly crystalline low-silica zeolite P during Na–Ca ion exchange. Microporous Mesoporous Mater 34(2):207–211

Stepkowska ET, Aviles MA, Blanes JM, Pérez-Rodríguez JL (2007) Gradual transformation of Ca(OH)2 into CaCO3 on cement hydration. XRD study. J Therm Anal Calorim 87(1):189–198

Eugster HP (1966) Sodium carbonate-bicarbonate minerals as indicators of PCO2. J Geophys Res 71(14):3369–3377

Zaitsev AN, Keller J, Spratt J, Perova EN, Kearsley A (2008) Nyerereite–pirsonnite–calcite–shortite relationships in altered natrocarbonatites, oldoinyo lengai, Tanzania. Can Miner 46:483–860

Dheilly R-M, Tudo J (1997) Contribution à létude de la gaylussite: Na2Ca(CO3)2, 5H2O. C R de l’Académie des Sci Ser IIB Mech Phys Chem Astron 325(7):407–414

Chen JJ, Thomas JJ, Jennings HM (2006) Decalcification shrinkage of cement paste. Cem Concr Res 36(5):801–809

Acknowledgments

This study was sponsored by the Australian Research Council (ARC) through a linkage grant between University of Melbourne and Zeobond Pty, including partial funding through the Particulate Fluids Processing Centre, a Special Research Centre of the ARC. The participation of R. Mejía de Gutiérrez was funded by Universidad del Valle (Colombia) and the GEOCERAM Project. The authors would like to express their gratitude to William Valencia and Jherson Díaz (Univalle) for carbonation depth data collection, and Brant Walkley (UniMelb) for his assistance in the difficult task of obtaining the carbonated paste from the hardened concretes for the XRD analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bernal, S.A., San Nicolas, R., Provis, J.L. et al. Natural carbonation of aged alkali-activated slag concretes. Mater Struct 47, 693–707 (2014). https://doi.org/10.1617/s11527-013-0089-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-013-0089-2