Abstract

This paper investigates the dynamic behavior of a V-shaped atomic force microscope (AFM) beam using different polymers and immersion environments. Polystyrene (PS), polypropylene (PP), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and high-impact polystyrene (HIPS) polymers have been used as the polymeric samples. Based on the importance and applications of these polymers in micro- and nanotechnology, it is necessary to find the mechanical properties in nanoscale. Considering these samples for AFM beam as new research can be interesting. Nanoindentation for extension and retraction regimes has been done by NT-MDT SOLVER P47 scanning probe microscope. For calibration of computing in nanoscale, polyethylene and EPDM rubber have been applied. For the mathematical modeling of the dynamic behavior of the V-shaped AFM beam, Timoshenko beam theory has been applied, and for modeling the contact between beam and samples, DMT (Derjaguin–Muller–Toporov) contact theory has been used to consider the adhesion due to a soft sample. Air, water, methanol, and acetone have been considered as beam environments. Finite element modeling (FEM) has been used to obtain the frequency response function (FRF) and resonant frequency of the beam. Mathematica software (version 8) has been used for programming equations in FEM. The results show that increasing the elasticity modules of the samples increases the resonant frequency, but the amplitude of FRF of vertical movement of the beam declines. By increasing the liquid viscosity as the immersion environments, the resonant frequency amplitude of FRF of vertical movement of the beam decreases. The results of theoretical modeling have been compared with the experimental method (by JPK Instruments-Nano Wizard 2 Atomic Force Microscope). The results show agreement.

Similar content being viewed by others

Abbreviations

- A :

-

Area of the cross section

- AFM:

-

Atomic force microscope

- \(c_{a}\) :

-

Additional hydrodynamic damping for rectangular cantilever

- \(c^{\prime}_{a}\) :

-

Additional hydrodynamic damping for double tapered cantilever

- \(c_{\infty }\) :

-

Hydrodynamic damping for rectangular cantilever when the cantilever is vibrating in free liquid

- \(c^{\prime}_{\infty }\) :

-

Hydrodynamic damping for double tapered cantilever when the cantilever is vibrating in free liquid

- \(c_{s}\) :

-

Hydrodynamic damping for rectangular cantilever when the cantilever is close to the surface

- \(c^{\prime}_{s}\) :

-

Hydrodynamic damping for double tapered cantilever when the cantilever is close to the surface

- \(C_{b}\) :

-

Breadth taper ratio

- \(C_{h}\) :

-

Height taper ratio

- d :

-

Distance between the lower edge of the cantilever and the centroid of the cross section

- D:

-

Equilibrium tip–sample separation between the cantilever tip and the sample surface

- \(D_{0}\) :

-

Initial beam deflection

- E :

-

Young's modulus

- \(E_{r}\) :

-

Declined elastic modulus of the tip–sample contact

- \(E_{t}\) :

-

Young's modulus of the tip

- \(E_{s}\) :

-

Young's modulus of the sample

- \(F_{ts}\) :

-

Tip–sample force vector

- \(f_{ts}\) :

-

Forces and moments at contact node

- \(f_{t} ,f_{n}\) :

-

Interaction forces in tangential and normal directions of sample surface

- \(f_{{d_{1} }}\) :

-

Hydrodynamic force for rectangular cantilever

- \(f_{{d_{2} }}\) :

-

Hydrodynamic force for double tapered cantilever

- G :

-

Shear modulus

- \(G_{t}\) :

-

Shear modulus of the tip

- \(G_{s}\) :

-

Shear modulus s of the sample

- H :

-

Distance from the natural axis of the beam to the top of the tip

- \(h(x,t)\) :

-

The transient distance between the rectangular cantilever and the surface

- \(h^{\prime}(x,t)\) :

-

The transient distance between the double tapered cantilever and the surface

- I :

-

Moment of the cross section

- k :

-

Shear coefficient

- \(k_{c}\) :

-

Cantilever contact stiffness

- \(k_{n} ,k_{t}\) :

-

Linear normal and lateral contact stiffness of the sample surface

- \(k_{n1} ,k_{n2} ,k_{t1} ,k_{t2}\) :

-

Non-linear normal and lateral contact stiffness of the sample surface

- kAG :

-

Shear rigidity

- \(K_{T - S}\) :

-

Matrix stiffness coefficient of the tip–sample interaction force

- \(k_{c}\) :

-

Beam stiffness

- \(k_{ts}\) :

-

Matrix stiffness exacts at the end of cantilever

- \(m_{{{\text{tip}}}}\) :

-

Tip mass

- N :

-

The number of total discrete grid points in the domain

- P :

-

Applied force

- r :

-

Timoshenko beam parameter to describe the rotatory inertia effect

- \(R_{t}\) :

-

Tip radius

- s :

-

Parameter to describe the shear deformation effect

- t :

-

Time

- w :

-

Transverse deflection of the cantilever

- x :

-

Longitudinal coordinate

- y :

-

General transverse deflection of the cantilever

- t :

-

Time

- \(Z_{0}\) :

-

Surface offset

- \(\xi\) :

-

Longitudinal coordinate parameter for the cantilever

- α :

-

Angle between the cantilever and sample surface

- λ :

-

Non dimensional resonant frequency parameter

- ρ :

-

Mass density

- \(\rho_{a}\) :

-

Additional mass density

- ρA :

-

Mass per unit length

- \(\mu\) :

-

Dimensionless

- Φ,:

-

Bending angles of the cantilever

- ω :

-

Circular resonant frequency

- \(\Lambda\) :

-

Tip–sample contact stiffness

- \(\delta\) :

-

Vertical displacement of piezoelectric scanner

- \(\delta^{\prime}\) :

-

Vertical displacement of tip

- \(\delta_{0}\) :

-

Static contact deformation

- \(\eta\) :

-

Density of the liquid

- ν :

-

Poisson's ratio

- \(\nu_{t}\) :

-

Poisson’s ratio of the tip

- \(\nu_{s}\) :

-

Poisson’s ratio of the sample

References

G. Binning, C.F. Quate, C. Gerber, Atomic force microscope. Phys. Rev. Lett. 56(9), 930–933 (1986)

U. Rabe, S. Hirsekorn, M. Reinstädtler, T. Sulzbach, C.H. Lehrer, W. Arnold, Influence of the cantilever holder on the vibrations of AFM cantilevers. Nanotechnology 18(4), 044008 (2007)

O. Sahin, S. Magonov, C. Su, C.F. Quate, O. Solgaard, An atomic force microscope tip designed to measure time-varying nanomechanical forces. Nat. Nanotechnol. 2, 507–514 (2007)

S. Eslami, N. Jalili, A comprehensive modeling and vibration analysis of AFM microcantilevers subjected to nonlinear tip-sample interaction forces. Ultramicroscopy 117, 31–45 (2012)

A. Sadeghi, The flexural vibration of V shaped atomic force microscope cantilevers by using the Timoshenko beam theory. ZAMM J. Appl. Math. Mech. 92(10), 782–800 (2012)

A.F. Payam, Sensitivity of flexural vibration mode of the rectangular atomic force microscope micro cantilevers in liquid to the surface stiffness variations. Ultramicroscopy 135, 84–88 (2013)

A.H. Korayem, A. Mashhadian, M.H. Korayem, Vibration analysis of different AFM cantilever with a piezoelectric layer in the vicinity of rough surfaces. Eur. J. Mech. A Solids 65, 313–323 (2017)

A.H. Korayem, A. Alipour, D. Younesian, Vibration suppression of atomic-force microscopy cantilevers covered by a piezoelectric layer with tensile force. J. Mech. Sci. Technol. 32, 4135–4144 (2018)

T.T.H. Hoang, S. Verma, S. Ma, T.T. Fister, J. Timoshenko, A.I. Frenkel, P.J.A. Kenis, A.A. Gewirth, Nanoporous copper–silver alloys by additive-controlled electrodeposition for the selective electroreduction of CO2 to ethylene and ethanol. J. Am. Chem. Soc. 140(17), 5791–5797 (2018)

M. Versaci, A. Jannelli, F.C. Morabito, G. Angiulli, A semi-linear elliptic model for a circular membrane MEMS device considering the effect of the fringing field. J. Sens. 21(15), 5237 (2021)

X.Y. Gao, Y.J. Guo, W.R. Shan, Shallow water in an open sea or a wide channel: auto- and non-auto-Bäcklund transformations with solitons for a generalized (2+1)-dimensional dispersive long-wave system. J. Chaos Solitons Fractals 138, 109950 (2020)

X.Y. Gao, Y.J. Guo, W.R. Shan, Water-wave symbolic computation for the Earth, Enceladus and Titan: the higher-order Boussinesq-Burgers system, auto- and non-auto-Bäcklund transformations. J. Appl. Math. Lett. 104, 106170 (2020)

C.R. Zhang, B. Tian, Q.X. Qu, L. Liu, H.Y. Tian, Vector bright solitons and their interactions of the couple Fokas–Lenells system in a birefringent optical fiber. J. Z. Angew. Math. Phys. 71(18), 1–19 (2020)

S.S. Chen, B. Tian, J. Chai, X.Y. Wu, D. Zhong, Lax pair, binary Darboux transformations and dark-soliton interaction of a fifth-order defocusing nonlinear Schrödinger equation for the attosecond pulses in the optical fiber communication. Waves Random Complex Media 30(3), 389–402 (2020)

M. Wnag, B. Tian, Y. Sun, Z. Zhang, Lump, mixed lump-stripe and rogue wave-stripe solutions of a (3+1)-dimensional nonlinear wave equation for a liquid with gas bubbles. J. Comput. Math. Appl. 79(3), 576–587 (2020)

X.Y. Gao, Y.J. Guo, W.R. Shan, Hetero-Bäcklund transformation and similarity reduction of an extended (2+1)-dimensional coupled Burgers system in fluid mechanics. J. Phys. Lett. A 384(3), 126788 (2020)

X.Y. Gao, Y.J. Guo, W.R. Shan, Cosmic dusty plasmas via a (3+1)-dimensional generalized variable-coefficient Kadomtsev–Petviashvili–Burgers-type equation: auto-Bäcklund transformations, solitons and similarity reductions plus observational/experimental supports. J. Waves Random Complex Media (in Press) (2021)

B. Tang, A.H.W. Ngan, J.B. Pethica, A method to quantitatively measure the elastic modulus of materials in nanometer scale using atomic force microscopy. Nanotechnology 19(49), 495713 (2008)

S.P. Timoshenko, J.N. Goodier, Theory of Elasticity (McGraw-Hill, New York, 1951)

H. Hosaka, K. Itao, S. Kuroda, Damping characteristics of beam-shaped micro-oscillators. J. Sens. Actuators 49, 87–95 (1995)

B.V. Derjaguin, V.M. Muller, Y.P. Toporov, Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 53, 314–326 (1975)

J.A. Turner, Non-linear Vibrations of a Beam with Cantilever-Hertzian Contact Boundary Conditions. J. Sound Vib. 275, 177–191 (2004)

Y. Song, B. Bhushan, Simulation of dynamic modes of atomic force microscopy using a 3D finite element model. J. Ultramicrosc. 106, 847–873 (2006)

F.Y. Cheng, Matrix Analysis of Structural Dynamics (MARCEL DEKKER, INC., New York, 2001)

C.Q. Wang, H. Wang, G.H. Gu, J.G. Fu, Q.Q. Lin, Y.N. Liu, Interfacial interactions between plastic particles in plastics flotation. Waste Manag. 46, 56–61 (2015)

Q. Shen, New insight on critical Hamaker constant of solid materials. Mater. Res. Bull. 133, 111082 (2021)

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A. Timoshenko beam model

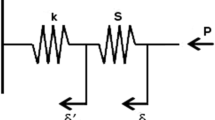

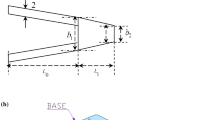

Here mass, stiffness, and damping matrices (Fig. 27) are introduced using Timoshenko beam principle [24]:

where \([m_{t} ]_{e}\) and \([m_{r} ]_{e}\) represent the mass matrix for shear inertia and rotatory inertia effects, respectively.

where \(\phi = \frac{12\,EI}{{kGA\,L^{2} }},A_{i} = \frac{{EI_{i} - EI_{j} }}{{EI_{i} + EI_{j} }},\quad \overline{EI} = (EI_{i} + EI_{j} )/2\). We employ the proportional damping matrix as [13]:

Appendix B. Hamaker constant

Based on the EDLVO principle, \(A_{132}\) as the Hamaker constant between material 1 and 2 in the medium 3 can be expressed as [15]:

Here, silicon tip has been supposed as the material 2 and polymeric samples are considered as the material 1. Air, water, methanol, and acetone have been used as the medium. Based on [15, 16], Table 8 cab be expressed as:

Rights and permissions

About this article

Cite this article

Rezaei, I., Sadeghi, A. Vibrational behavior of atomic force microscope beam via different polymers and immersion environments. Eur. Phys. J. Plus 137, 72 (2022). https://doi.org/10.1140/epjp/s13360-021-02283-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-02283-1