Abstract

We investigate the Johari–Goldstein (JG) \(\beta \)-relaxation process in a model metallic glass-forming (GF) material (\(\hbox {Al}_{90}\hbox {Sm}_{10}\)), previously studied extensively by both frequency-dependent mechanical measurements and simulation studies devoted to equilibrium properties, by molecular dynamics simulations based on validated and optimized interatomic potentials with the primary aim of better understanding the nature of this universal relaxation process from a dynamic heterogeneity (DH) perspective. The present relatively low temperature and long-time simulations reveal a direct correspondence between the JG \(\beta \)-relaxation time \(\tau _\mathrm{JG}\) and the lifetime of the mobile particle clusters \(\tau _\mathrm{M}\), defined as in previous DH studies, a relationship dual to the corresponding previously observed relationship between the \(\alpha \)-relaxation time \(\tau _{\alpha }\) and the lifetime of immobile particle clusters \(\tau _\mathrm{IM}\). Moreover, we find that the average diffusion coefficient D nearly coincides with \(D_\mathrm{Al}\) of the smaller atomic species (Al) and that the ‘hopping time’ associated with D coincides with \(\tau _\mathrm{JG}\) to within numerical uncertainty, both trends being in accord with experimental studies. This indicates that the JG \(\beta \)-relaxation is dominated by the smaller atomic species and the observation of a direct relation between this relaxation process and rate of molecular diffusion in GF materials at low temperatures where the JG \(\beta \)-relaxation becomes the prevalent mode of structural relaxation. As an unanticipated aspect of our study, we find that \(\hbox {Al}_{90}\hbox {Sm}_{10}\) exhibits fragile-to-strong (FS) glass formation, as found in many other metallic GF liquids, but this fact does not greatly alter the geometrical nature of DH in this material and the relation of DH to dynamical properties. On the other hand, the temperature dependence of the DH and dynamical properties, such as the structural relaxation time, can be significantly altered from ‘ordinary’ GF liquids.

Graphic abstract

Similar content being viewed by others

Data Availability Statements

The data that support the findings of this study are available within the article and its supplementary material.

References

B.A.P. Betancourt, F.W. Starr, J.F. Douglas, J. Chem. Phys. 148(10), 104508 (2018)

A. Giuntoli, F. Puosi, D. Leporini, F. Starr, J.F. Douglas, Sci. Adv. 6(17), eaaz0777 (2020)

H.B. Yu, K. Samwer, Y. Wu, W.H. Wang, Phys. Rev. Lett. 109(9), 095508 (2012)

H. Zhang, X.Y. Wang, H.B. Yu, J.F. Douglas, J. Chem. Phys. 154, 084505 (2021)

K.L. Ngai, Phys. Rev. E 57(6), 7346 (1998)

K.L. Ngai, S. Capaccioli, Phys. Rev. E 69(3), 031501 (2004)

F.W. Starr, J.F. Douglas, S. Sastry, J. Chem. Phys. 138(12), 12A541 (2013)

H. Zhang, C. Zhong, J.F. Douglas, X.D. Wang, Q.P. Cao, D.X. Zhang, J.Z. Jiang, J. Chem. Phys. 142(16), 164506 (2015)

H.B. Yu, R. Richert, K. Samwer, Sci. Adv. 3(11), e1701577 (2017)

Y. Sun, S.X. Peng, Q. Yang, F. Zhang, M.H. Yang, C.Z. Wang, K.M. Ho, H.B. Yu, Phys. Rev. Lett. 123(10), 105701 (2019)

X.Y. Wang, W.S. Xu, H. Zhang, J.F. Douglas, J. Chem. Phys. 151(18), 184503 (2019)

Q.J. Sun, C. Zhou, Y.Z. Yue, L.N. Hu, J. Phys. Chem. Lett. 5(7), 1170 (2014)

H. Vogel, Phys. Z. 22, 645 (1921)

G.S. Fulcher, J. Am. Ceram. Soc. 8(6), 339 (1925)

G. Tammann, W. Hesse, Z. Anorg, Allg. Chem. 156(4), 14 (1926)

B.A.P. Betancourt, J.F. Douglas, F.W. Starr, J. Chem. Phys. 140(20), 204509 (2014)

M.I. Mendelev, F. Zhang, Z. Ye, Y. Sun, M.C. Nguyen, S.R. Wilson, C.Z. Wang, K.M. Ho, Model Simul. Mater. Sci. 23(4), 11 (2015)

M.W. Finnis, J.E. Sinclair, Philos. Mag. A 50(1), 45 (1984)

Y. Sun, Y. Zhang, F. Zhang, Z. Ye, Z.J. Ding, C.Z. Wang, K.M. Ho, J. Appl. Phys. 120(1), 015901 (2016)

M. Parrinello, A. Rahman, J. Appl. Phys. 52(12), 7182 (1981)

S. Nose, J. Chem. Phys. 81(1), 511 (1984)

W.G. Hoover, Phys. Rev. A 31(3), 1695 (1985)

S. Plimpton, J. Comput. Phys. 117(1), 1 (1995)

D. Bedrov, G.D. Smith, Phys. Rev. E 71(5), 050801 (2005)

A. Tripodo, F. Puosi, M. Malvaldi, S. Capaccioli, D. Leporini, Polymers 12(4), 761 (2020)

Y. Sun, F. Zhang, Z. Ye, Y. Zhang, X.W. Fang, Z.J. Ding, C.Z. Wang, M.I. Mendelev, R.T. Ott, M.J. Kramer, K.M. Ho, Sci. Rep. Uk 6, 23734 (2016)

L. Yang, F. Zhang, F.Q. Meng, L. Zhou, Y. Sun, X. Zhao, Z. Ye, M.J. Kramer, C.Z. Wang, K.M. Ho, Acta Mater. 156, 97 (2018)

L. Wang, J.J. Hoyt, N. Wang, N. Provatas, C.W. Sinclair, Nat. Commun. 11(1), 7 (2020)

Y.Q. Cheng, E. Ma, Prog. Mater Sci. 56(4), 379 (2011)

J. Ding, E. Ma, N.P.J. Comput, Mater. 3, 12 (2017)

H.W. Sheng, W.K. Luo, F.M. Alamgir, J.M. Bai, E. Ma, Nature 439(7075), 419 (2006)

M. Li, C.Z. Wang, S.G. Hao, M.J. Kramer, K.M. Ho, Phys. Rev. B 80(18), 184201 (2009)

A.R. Yavari, Nature 439(7075), 405 (2006)

A. Hirata, P.F. Guan, T. Fujita, Y. Hirotsu, A. Inoue, A.R. Yavari, T. Sakurai, M.W. Chen, Nat. Mater. 10(1), 28 (2011)

F. Zhu, A. Hirata, P. Liu, S.X. Song, Y. Tian, J.H. Han, T. Fujita, M.W. Chen, Phys. Rev. Lett. 119(21), 215501 (2017)

G.V. Jensen, R. Lund, J. Gummel, T. Narayanan, J.S. Pedersen, Angew. Chem. Int. Edit. 53(43), 11524 (2014)

P.P. Sun, F. Lu, A.L. Wu, L.J. Shi, L.Q. Zheng, Soft Matter 13(13), 2543 (2017)

P. Schurtenberger, C. Cavaco, F. Tiberg, O. Regev, Langmuir 12(12), 2894 (1996)

S. Jain, J.B. Udgaonkar, J. Mol. Biol. 382(5), 1228 (2008)

J. Dudowicz, K.F. Freed, J.F. Douglas, J. Chem. Phys. 113(1), 434 (2000)

C.A. Ross, M.A. Poirier, Nat. Med. 10(7), S10 (2004)

Y.H. Liu, D. Wang, K. Nakajima, W. Zhang, A. Hirata, T. Nishi, A. Inoue, M.W. Chen, Phys. Rev. Lett. 106(12), 125504 (2011)

C.Y. Liu, R. Maass, Adv. Funct. Mater. 28(30), 1800388 (2018)

S. Aasland, P.F. McMillan, Nature 369(6482), 633 (1994)

S. Wei, F. Yang, J. Bednarcik, I. Kaban, O. Shuleshova, A. Meyer, R. Busch, Nat. Commun. 4, 2083 (2013)

J. Shen, Z. Lu, J.Q. Wang, S. Lan, F. Zhang, A. Hirata, M.W. Chen, X.L. Wang, P. Wen, Y.H. Sun, H.Y. Bai, W.H. Wang, J. Phys. Chem. Lett. 11(16), 6718 (2020)

H. Tanaka, R. Kurita, H. Mataki, Phys. Rev. Lett. 92(2), 025701 (2004)

M. Zhu, J.Q. Wang, J.H. Perepezko, L. Yu, J. Chem. Phys. 142(24), 244504 (2015)

M. Kobayashi, H. Tanaka, Nat. Commun. 7, 13438 (2016)

P.H. Poole, T. Grande, C.A. Angell, P.F. McMillan, Science 275(5298), 322 (1997)

O. Mishima, H.E. Stanley, Nature 396(6709), 329 (1998)

P.G. Debenedetti, F. Sciortino, G.H. Zerze, Science 369(6501), 289 (2020)

L. Kringle, W.A. Thornley, B.D. Kay, G.A. Kimmel, Science 369(6510), 1490 (2020)

Y. Katayama, T. Mizutani, W. Utsumi, O. Shimomura, M. Yamakata, K. Funakoshi, Nature 403(6766), 170 (2000)

J.N. Glosli, F.H. Ree, Phys. Rev. Lett. 82(23), 4659 (1999)

A.V. Tobolsky, A. Eisenberg, J. Am. Chem. Soc. 81(4), 780 (1959)

S.C. Greer, J. Phys. Chem. B 102(28), 5413 (1998)

L.J. Zhang, Y. Ren, X.R. Liu, F. Han, K. Evans-Lutterodt, H.Y. Wang, Y.L. He, J.L. Wang, Y. Zhao, W.G. Yang, Sci. Rep. 8, 4558 (2018)

L. Henry, M. Mezouar, G. Garbarino, D. Sifre, G. Weck, F. Datchi, Nature 584(7821), 382 (2020)

D. Hohl, R.O. Jones, Phys. Rev. B 50(23), 17047 (1994)

R. Bohmer, C.A. Angell, Phys. Rev. B 48(9), 5857 (1993)

C. Bichara, A. Pellegatti, J.P. Gaspard, Phys. Rev. B 49(10), 6581 (1994)

J. Kalikka, J. Akola, R.O. Jones, H.R. Schober, Phys. Rev. B 102(10), 104202 (2020)

Y. Tsuchiya, J. Non-Cryst, Solids 156, 700 (1993)

Y. Tsuchiya, J. Non-Cryst, Solids 312–14, 212 (2002)

J. Akola, R.O. Jones, S. Kohara, T. Usuki, E. Bychkov, Phys. Rev. B 81(9), 094202 (2010)

J. Akola, R.O. Jones, Phys. Rev. B 85(13), 134103 (2012)

G.C. Sosso, J. Colombo, J. Behler, E. Del Gado, M. Bernasconi, J. Phys. Chem. B 118(47), 13621 (2014)

D.A.C. Jara, M.F. Michelon, A. Antonelli, M. de Koning, J. Chem. Phys. 130(22), 221101 (2009)

R.Z. Li, G. Sun, L.M. Xu, J. Chem. Phys. 145(5), 054506 (2016)

H. Tanaka, J. Chem. Phys. 153, 130901 (2020)

A.V. Anikeenko, N.N. Medvedev, Phys. Rev. Lett. 98(23), 235504 (2007)

C.A. Angell, Solid State Sci. 2(8), 791 (2000)

C.A. Angell, C.T. Moynihan, M. Hemmati, J. Non-Cryst, Solids 274(1–3), 319 (2000)

S. Torquato, Phys. Rep. Rev. Sec. Phys. Lett. 745, 1 (2018)

W.S. Xu, J.F. Douglas, K.F. Freed, Macromolecules 49(21), 8341 (2016)

C.A. Angell, J. Phys. Chem. 75(24), 3698 (1971)

C.T. Moynihan, C.A. Angell, J. Non-Cryst, Solids 274(1–3), 131 (2000)

H. Zhang, X.Y. Wang, A. Chremos, J.F. Douglas, J. Chem. Phys. 150, 174506 (2019)

D.A. Porter, K.E. Easterling, Phase Transformations in Metals and Alloys, 2nd edn. (Chapman & Hall, London, 1993)

G. Adam, J.H. Gibbs, J. Chem. Phys. 43(1), 139 (1965)

A.M. Brown, M.F. Ashby, Acta Metall. Mater. 28(8), 1085 (1980)

R.H. Doremus, J. Appl. Phys. 92(12), 7619 (2002)

F. Faupel, W. Frank, M.P. Macht, H. Mehrer, N.V.K. Ratzke, H.R. Schober, S.K. Sharma, H. Teichler, Rev. Mod. Phys. 75(1), 237 (2003)

J.F. Douglas, B.A.P. Betancourt, X.H. Tong, H. Zhang, J. Stat. Mech. Theory E 2016, 054048 (2016)

G. Boisvert, L.J. Lewis, A. Yelon, Phys. Rev. Lett. 75(3), 469 (1995)

G. Boisvert, N. Mousseau, L.J. Lewis, Phys. Rev. B 58(19), 12667 (1998)

S. Ryu, K. Kang, W. Cai, Proc. Natl. Acad. Sci. USA 108(13), 5174 (2011)

B.A.P. Betancourt, P.Z. Hanakata, F.W. Starr, J.F. Douglas, Proc. Natl. Acad. Sci. USA 112(10), 2966 (2015)

P.A. O’Connell, G.B. McKenna, J. Chem. Phys. 110(22), 11054 (1999)

V.N. Novikov, A.P. Sokolov, Phys. Rev. E 92(6), 062304 (2015)

C.A. Angell, Science 267(5206), 1924 (1995)

E.B. Stukalin, J.F. Douglas, K.F. Freed, J. Chem. Phys. 131(11), 114905 (2009)

K. Ito, C.T. Moynihan, C.A. Angell, Nature 398(6727), 492 (1999)

R. Shi, J. Russo, H. Tanaka, Proc. Natl. Acad. Sci. USA 115(38), 9444 (2018)

R. Shi, J. Russo, H. Tanaka, J. Chem. Phys. 149(22), 224502 (2018)

J.F. Douglas, J.B. Hubbard, Macromolecules 24(11), 3163 (1991)

W.G. Zhang, J.F. Douglas, F.W. Starr, J. Chem. Phys. 147(4), 044901 (2017)

T. Scopigno, U. Balucani, G. Ruocco, F. Sette, Phys. Rev. E 65(3), 031205 (2002)

E. Guillaud, S. Merabia, D. de Ligny, L. Joly, Phys. Chem. Chem. Phys. 19(3), 2124 (2017)

J.-P. Boon, S. Yip, Molecular Hydrodynamics (Dover Publications, New York, 1991)

J.F. Douglas, Comput. Mater. Sci. 4(4), 292 (1995)

J.F. Douglas, D. Leporini, J. Non Cryst. Solids 235, 137 (1998)

S.H. Chen, F. Mallamace, C.Y. Mou, M. Broccio, C. Corsaro, A. Faraone, L. Liu, Proc. Natl. Acad. Sci. USA 103(35), 12974 (2006)

P. Kumar, Proc. Natl. Acad. Sci. USA 103(35), 12955 (2006)

I.N. Tsimpanogiannis, S.H. Jamali, I.G. Economou, T.J.H. Vlugt, O.A. Moultos, Mol. Phys. 118(9–10), e1702729 (2020)

H. Zhang, D.J. Srolovitz, J.F. Douglas, J.A. Warren, Proc. Natl. Acad. Sci. USA 106(19), 7735 (2009)

H. Zhang, P. Kalvapalle, J.F. Douglas, Soft Matter 6(23), 5944 (2010)

D. Stauffer, A. Aharony, Introduction to Percolation Theory, 2nd edn. (Taylor & Francis, London, 1994)

J.F. Douglas, Phys. Rev. E 54(3), 2677 (1996)

N. Giovambattista, S.V. Buldyrev, H.E. Stanley, F.W. Starr, Phys. Rev. E 72(1), 011202 (2005)

K. Solc, J. Chem. Phys. 55(1), 335 (1971)

A. Chremos, C. Jeong, J.F. Douglas, Soft Matter 13(34), 5778 (2017)

H. Zhang, M. Khalkhali, Q.X. Liu, J.F. Douglas, J. Chem. Phys. 138(12), 12A538 (2013)

E.B. Stukalin, J.F. Douglas, K.F. Freed, J. Chem. Phys. 129(9), 094901 (2008)

J.F. Douglas, J. Phys. Condens. Mat. 11(10A), A329 (1999)

W. Min, G.B. Luo, B.J. Cherayil, S.C. Kou, X.S. Xie, Phys. Rev. Lett. 94(19), 198302 (2005)

E. Rossler, Phys. Rev. Lett. 65(13), 1595 (1990)

T. Fujima, H. Frusawa, K. Ito, Phys. Rev. E 66(3), 031503 (2002)

K. Nordlund, Y. Ashkenazy, R.S. Averback, A.V. Granato, Europhys. Lett. 71(4), 625 (2005)

E.R. Weeks, J.C. Crocker, A.C. Levitt, A. Schofield, D.A. Weitz, Science 287(5453), 627 (2000)

J.C. Slater, J. Chem. Phys. 41(10), 3199 (1964)

M.T. Cicerone, Q. Zhong, M. Tyagi, Phys. Rev. Lett. 113(11), 117801 (2014)

M.T. Cicerone, M. Tyagi, J. Chem. Phys. 146(5), 054502 (2017)

B.Y. Cui, Z. Evenson, B.B. Fan, M.Z. Li, W.H. Wang, A. Zaccone, Phys. Rev. B 98(14), 144201 (2018)

H.B. Yu, K. Samwer, W.H. Wang, H.Y. Bai, Nat. Commun. 4, 2204 (2013)

T. Psurek, C.L. Soles, K.A. Page, M.T. Cicerone, J.F. Douglas, J. Phys. Chem. B 112(50), 15980 (2008)

G.P. Johari, J. Non Cryst. Solids 307, 317 (2002)

K.F. Freed, J. Chem. Phys. 141(14), 141102 (2014)

W.S. Xu, J.F. Douglas, Z.Y. Sun, Macromolecules (2021)

W.S. Xu, J.F. Douglas, W.J. Xia, X.L. Xu, Macromolecules 53(16), 6828 (2020)

P.Z. Hanakata, B.A.P. Betancourt, J.F. Douglas, F.W. Starr, J. Chem. Phys. 142(23), 234907 (2015)

W.S. Xu, J.F. Douglas, K.F. Freed, Macromolecules 50(6), 2585 (2017)

P.Z. Hanakata, J.F. Douglas, F.W. Starr, Nat. Commun. 5, 4163 (2014)

W.G. Zhang, F.W. Starr, J.F. Douglas, J. Chem. Phys. 152(12), 124703 (2020)

W.S. Xu, J.F. Douglas, K.F. Freed, J. Chem. Phys. 145(23), 234509 (2016)

G. Kohring, R.E. Shrock, P. Wills, Phys. Rev. Lett. 57(11), 1358 (1986)

G.A. Williams, Phys. Rev. Lett. 59(17), 1926 (1987)

G.A. Williams, Phys. Rev. Lett. 82(6), 1201 (1999)

A.K. Nguyen, A. Sudbo, Phys. Rev. B 60(22), 15307 (1999)

N.D. Antunes, L.M.A. Bettencourt, M. Hindmarsh, Phys. Rev. Lett. 80(5), 908 (1998)

N.D. Antunes, L.M.A. Bettencourt, Phys. Rev. Lett. 81(15), 3083 (1998)

N.D. Antunes, L.M.A. Bettencourt, A. Yates, Phys. Rev. D 64(6), 065020 (2001)

H. Hocker, G.J. Blake, P.J. Flory, Trans. Faraday Soc. 67(584), 2251 (1971)

L.L. Gong, X.Y. Zhang, Y. Shi, Eur. Polym. J. 47(10), 1931 (2011)

A.M. Lobanov, S.Y. Frenkel, Vysokomol. Soedin. Ser. A 22(5), 1045 (1980)

B. Maxwell, K.S. Cook, J. Polym. Sci. Polym. Symp. 72, 343 (1985)

S.S.N. Murthy, J. Polym. Sci. Pt. B Polym. Phys. 31(4), 475 (1993)

X.B. Wu, S.Y. Shang, Q.L. Xu, Z.G. Zhu, J. Appl. Phys. 103(7), 073519 (2008)

S.Y. Shang, Z.G. Zhu, Z.J. Lu, G.Z. Zhang, J. Phys. Conden. Matter 19(41), 416107 (2007)

R.Y. Qian, Y.S. Yu, Front. Chem. China 4(1), 1 (2009)

R.F. Boyer, Polym. Eng. Sci. 19(10), 732 (1979)

S. Hedvat, Polymer 22(6), 774 (1981)

I. Saika-Voivod, P.H. Poole, F. Sciortino, Nature 412(6846), 514 (2001)

E.D. Cubuk, A.J. Liu, E. Kaxiras, S.S. Schoenholz, arXiv:2008.09681 [cond-mat.soft] (2020)

C.A. Angell, K.L. Ngai, G.B. McKenna, P.F. McMillan, S.W. Martin, J. Appl. Phys. 88(6), 3113 (2000)

Y.S. Elmatad, D. Chandler, J.P. Garrahan, J. Phys. Chem. B 113(16), 5563 (2009)

J.C. Mauro, Y.Z. Yue, A.J. Ellison, P.K. Gupta, D.C. Allan, Proc. Natl. Acad. Sci. USA 106(47), 19780 (2009)

P. Lucas, J. Non-Cryst, Solids X 4, 100034 (2019)

J.F. Douglas, J. Dudowicz, K.F. Freed, J. Chem. Phys. 125(14), 144907 (2006)

J.F. Douglas, J. Dudowicz, K.F. Freed, J. Chem. Phys. 128(22), 224901 (2008)

J. Dudowicz, K.F. Freed, J.F. Douglas, J. Chem. Phys. 111(15), 7116 (1999)

J. Dudowicz, K.F. Freed, J.F. Douglas, J. Chem. Phys. 119(23), 12645 (2003)

B. Jana, R.S. Singh, B. Bagchi, Phys. Chem. Chem. Phys. 13(36), 16220 (2011)

P. Gallo, K. Arnann-Winkel, C.A. Angell, M.A. Anisimov, F. Caupin, C. Chakravarty, E. Lascaris, T. Loerting, A.Z. Panagiotopoulos, J. Russo, J.A. Sellberg, H.E. Stanley, H. Tanaka, C. Vega, L.M. Xu, L.G.M. Pettersson, Chem. Rev. 116(13), 7463 (2016)

B.M. Voronin, S.V. Volkov, J. Phys. Chem. Solids 62(7), 1349 (2001)

H.E. Stanley, Introduction to Phase Transitions and Critical Phenomena (Oxford University Press, New York, 1971)

W.S. Xu, J.F. Douglas, K.F. Freed, Macromolecules 49(21), 8355 (2016)

C. Domb, J. Phys, Part. C Solid 3(2), 256 (1970)

C. Domb, J. Phys. Part. C Solid 5(12), 1399 (1972)

C. Domb, J. Phys. Part. C Solid 5(12), 1417 (1972)

J.F. Douglas, T. Ishinabe, Phys. Rev. E 51(3), 1791 (1995)

J.C. Wheeler, P. Pfeuty, J. Chem. Phys. 74(11), 6415 (1981)

J.C. Wheeler, Phys. Rev. Lett. 53(2), 174 (1984)

G. Hagg, J. Chem. Phys. 3(1), 42 (1935)

W.H. Zachariasen, J. Am. Chem. Soc. 54, 3841 (1932)

W.H. Zachariasen, J. Chem. Phys. 3(3), 162 (1935)

G. Hagg, J. Chem. Phys. 3(6), 363 (1935)

Y. Tsuchiya, Scand. J. Metall. 30(5), 345 (2001)

R. Kurita, K. Murata, H. Tanaka, Nat. Mater. 7(8), 647 (2008)

J. Dudowicz, J.F. Douglas, K.F. Freed, J. Phys. Chem. B 113(12), 3920 (2009)

Y. Tsuchiya, J. Phys-Condens, Mat. 6(13), 2451 (1994)

Y. Tsuchiya, F. Kakinuma, C. Bergman, J. Non-Cryst, Solids 205, 143 (1996)

M.V. Coulet, C. Bergman, R. Bellissent, C. Bichara, J. Non-Cryst, Solids 250, 463 (1999)

M.-V. Coulet, R. Bellissent, C. Bichara, J. Phys-Condens, Mat. 18(50), 11471 (2006)

E.H. Graf, D.M. Lee, J.D. Reppy, Phys. Rev. Lett. 19(8), 417 (1967)

P. Leiderer, W. Bosch, Phys. Rev. Lett. 45(9), 727 (1980)

R.P. Feynman, Phys. Rev. 90(6), 1116 (1953)

R.P. Feynman, Phys. Rev. 94(2), 262 (1954)

Z. Zhou, B. Chu, Macromolecules 27(8), 2025 (1994)

A. Huff, K. Patton, H. Odhner, D.T. Jacobs, B.C. Clover, S.C. Greer, Langmuir 27(5), 1707 (2011)

H.M. Tan, A. Moet, A. Hiltner, E. Baer, Macromolecules 16(1), 28 (1983)

K. Kawanishi, Y. Takeda, T. Inoue, Polym. J. 18(5), 411 (1986)

S.D. Feng, L. Qi, L.M. Wang, P.F. Yu, S.L. Zhang, M.Z. Ma, X.Y. Zhang, Q. Jing, K.L. Ngai, A.L. Greer, G. Li, R.P. Liu, Scr. Mater. 115, 57 (2016)

S. Wei, G.J. Coleman, P. Lucas, C.A. Angell, Phys. Rev. Appl. 7(3), 034035 (2017)

J. Orava, A.L. Greer, B. Gholipour, D.W. Hewak, C.E. Smith, Nat. Mater. 11(4), 279 (2012)

J. Orava, H. Weber, I. Kaban, A.L. Greer, J. Chem. Phys. 144(19), 194503 (2016)

Q. Du, X.J. Liu, H.Y. Fan, Q.S. Zeng, Y. Wu, H. Wang, D. Chatterjee, Y. Ren, Y.B. Ke, P.M. Voyles, Z.P. Lu, E. Ma, Mater. Today 34, 66 (2020)

C. Steimer, V. Coulet, W. Welnic, H. Dieker, R. Detemple, C. Bichara, B. Beuneu, J.P. Gaspard, M. Wuttig, Adv. Mater. 20(23), 4535 (2008)

P. Lucas, S. Wei, C.A. Angell, Int. J. Appl. Glass Sci. 11(2), 236 (2020)

S. Naserifar, W.A. Goddard, Proc. Natl. Acad. Sci. USA 116(6), 1998 (2019)

H. Kanno, H. Yokoyama, Y. Yoshimura, J. Phys. Chem. B 105(10), 2019 (2001)

Acknowledgements

H.Z. and X.Y.W. gratefully acknowledge the support of the Natural Sciences and Engineering Research Council of Canada under the Discovery Grant Program (RGPIN-2017-03814) and Accelerator Supplements (RGPAS-2017- 507975).

Author information

Authors and Affiliations

Corresponding authors

Supplementary Information

Below is the link to the electronic supplementary material.

Appendices

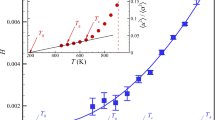

Appendix A: observations on the nature of the fragile–strong transition

Recently, it has been appreciated that glass formation in many materials can follow a strikingly different phenomenology than ‘ordinary’ glass-forming liquids, which are characterized by apparent activation energies \(E_{app}\) for their mass diffusion coefficients, structural relaxation times and viscosities in conventional Arrhenius plots that monotonically increase upon cooling, a pattern of relaxation that many models of glass formation have sought to rationalize. In some liquids, however, such as water and silica, and also many metallic GF materials as we will discuss below, \(E_{app}\) first increases rather sharply upon cooling, but then suddenly drops, and then \(E_{app}\) apparently becomes constant again in the glass state, taking a value much lower than its peak value at intermediate temperatures. Because of the change from a rapidly increasing \(E_{app}\) to a condition for which \(E_{app}\) is nearly constant, this type of GF liquid is said to have undergone a ‘fragile-to-strong’ transition. The term ‘fragility’ reflects the nomenclature of ordinary GF liquids for which liquids having a strong variation in their effective activation energy (slope in an Arrhenius plot) with T are termed ‘fragile,’ while those having a relatively weak T dependence are termed ‘strong.’ Paradoxically, these GF liquids exhibit both of these behaviors in their respective high and low T regimes of glass formation. While such materials at low T exhibit the rheological characteristics of a solid, justifying the term ‘glass,’ these materials clearly have some features that set them apart from ‘ordinary’ GF liquids. Another singular feature of materials undergoing this type of FS glass formation is that there is a well-defined peak in the specific heat \(C_{p}\) and extrema in other thermodynamic response functions (thermal expansion coefficient, isothermal compressibility) that signals some kind of thermodynamic transition phenomenon (not a phase transition because the peak is too rounded) and no observable transition or only a weak specific heat \(C_{p}\) feature arising from going out of equilibrium, as in ordinary GF materials. In contrast, there is no observable or only a weak [144, 145] thermodynamic signature of a ‘liquid–liquid’ transition in fluids exhibiting ‘ordinary’ glass formation, but \(C_{p}\) shows a large drop as the material goes out of equilibrium, a kinetic phenomenon that is normally taken as the definition of \(T_\mathrm{g}\).

We note that there has long been a discussion and controversy relating to a putative ‘liquid–liquid’ transition temperature \(T_{LL}\) in polymer melts, and other ‘ordinary’ GF liquids, whose value is typically reported to be in the range \(T_{LL} \approx \) (1.2 to 1.3) \(T_\mathrm{g}\). In particular, the weak theoretical rationale and subtle nature of the thermodynamic signature demonstrating the reality of such a transition has made this quantity controversial in the academic material science community, until recently, but the practical importance of this T is broadly recognized in the field process engineering because this T often signals gross changes in fluid flow and diffusion processes that are highly relevant for material processing [146,147,148,149,150,151,152,153]. We will see that GF fluids showing a FS transition exhibit a \(C_{p}\) peak that follows a similar phenomenology in relation to its position relative to \(T_\mathrm{g}\), but the intensity of the thermodynamic feature and the occurrence of anomalies in other thermodynamic response functions indicate that this characteristic T corresponds to a proper thermodynamic transition in the material. We take this as implying that there are possible unifying features in GF fluids exhibiting ordinary and FS glass formation. Our investigation of dynamic heterogeneity in a metallic GF liquid exhibiting FS glass formation further supports this essential unity in the physical nature of these materials, but it is not clear that any theoretical framework, or even correlative scheme, can encompass both classes of GF liquids. The theoretical challenge of developing a theory of the dynamics of GF liquids that encompasses both classes of materials then provides a good opportunity for improving our theoretical understanding of GF liquids broadly.

It is now clear after the discovery that water, silica and many metallic GF materials [12, 94,95,96, 154] follow the FS pattern of glass formation that this is actually a rather common type of glass formation. This brings us to the question of what essential physical features are shared by systems undergoing this type of glass formation and which are distinct. A recent study suggests that the softness, a structure parameter identified by machine learning, provides a good description of FS transition in silica [155]. In particular, we may wonder whether the dynamic heterogeneities in these GF liquids take a similar form in these apparently distinct classes of GF liquids and whether models that have been applied to the description of diffusion and relaxation in ordinary GF materials also phenomenologically describe these other materials. Evidently, the usual phenomenological equations of relaxation and diffusion in ordinary GF liquids, such as Vogel–Fulcher–Tammann equation, etc., and many others of more recent development [156,157,158], cannot describe the T dependence of diffusion and relaxation in materials exhibiting FS glass formation. Moreover, it is not clear whether the recently developed string model of glass formation [7, 16] can account for this pattern of relaxation, so a comparison of simulations to this model would provide an important test of this model. We further point out that this general pattern in non-Arrhenius diffusion in fluids undergoing a fragile-to-strong transition is also observed in simulations and measurements on superionic crystalline materials. A simulation study of the O ion diffusion coefficient \(D_{\mathrm{O}}\) in superionic \(\hbox {UO}_{2}\), [79] which is remarkably high for a crystalline material, explaining the term ‘superionic,’ indicted that the string model of glass formation could quantitatively describe \(D_{O}\) in this material at all T simulated so the applicability of the string model to describe GF liquids undergoing a FS transition cannot be ruled out a priori.

Appendix B: How do we explain the origin of the fragile–strong transition?

Although it is nice to know that the relation between collective motion and changing activation energy still applies to our metallic glass material undergoing a FS transition, we still have not answered why glass formation in this material, and many metallic and others materials [159], follows such a different pattern of glass formation thermodynamics and dynamics. Another feature of materials undergoing this type of FS glass formation is that there is a well-defined peak in the specific heat \(C_{p}\) and extrema in other thermodynamic response functions (thermal expansion coefficient, isothermal compressibility), signaling some kind of thermodynamic transition phenomenon. On the other hand, there is no observable or only a weak [144, 145] thermodynamic signature of such a ‘liquid–liquid’ transition in fluids exhibiting ‘ordinary’ glass formation. The hypothesis that systems exhibiting such thermodynamic transition features are exhibiting a kind of cooperative thermodynamic self-assembly transition [1, 16, 160] offers an attractive possibility for interpreting such systems. It is characteristic of materials exhibiting FS transitions to exhibit ‘anomalies’ in thermodynamic response functions [40, 57, 161,162,163] such as the specific heat, thermal expansion coefficient of the fluid, isothermal compressibility that accompany sharp changes in the viscosity and viscoelasticity of solution exhibiting supramolecular assembly (See Appendix A). These thermodynamic anomalies are well known in the case of water [96, 164], where they have often been attributed to a counter-intuitive liquid–liquid phase separation of water from itself, [165] a phenomenon arising from water’s capacity to exhibit a multiplicity of distinct local packing states having distinct thermodynamic and dynamic signatures-mobile high density water and low density immobile water [96]. It is then a matter of interest to consider whether these thermodynamic changes in response functions also arise in our metallic glass material to see if we can find any general thermodynamic clues about the nature of glass formation in this class of materials. Accordingly, we estimated the specific heat of our metallic glass material and the four-point density correlation \(\chi _{4}\) and find that this system indeed exhibits well-defined anomalies of a thermodynamic nature.

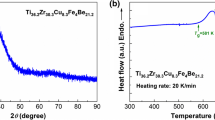

Observation of a lambda transition in the specific heat. Specific heat \(C_{p}\) at constant pressure for our \(\hbox {Al}_{{90}}~\hbox {Sm}_{{10}}\) metallic GF liquid as a function of T. We see that \(C_{p}\) normalized by the gas constant R exhibits a peak around 750 K, a temperature not far from the lambda transition temperature \(T_{\lambda }\) identified in the differential activation energy plot shown in Fig. 1b. Superionic crystalline materials also exhibit a rounded specific heat anomaly consistent with a rounded thermodynamic transition. [166] Note that this peak is not the result of falling out of equilibrium, but rather represents a true thermodynamic transition of some kind. See Refs. [95, 96], and [164] for discussion of the lambda transition in water

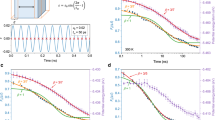

We first consider the specific heat at constant pressure \(C_{p}\) in Fig. 20 where we see that \(C_{p}\) exhibits a rounded peak, consistent with a mildly cooperative self-assembly transition [161]. It is characteristic of such self-assembly transitions that they are ‘rounded’ so that are no singularities exist in the free energy that give rise to divergence in any response functions, as found in second order phase transitions [167]. Next, we consider the 4-point density autocorrelation function which should provide information about density fluctuations accompanying self-assembly. To define this quantity, first, we define time-dependent self-overlap function \(Q_{s}\left( t \right) \), [168]

when \(\sigma \left| r_{j}\left( t \right) -r_{j}\left( 0 \right) \right| <0.3\), \(\omega = 1\), and when \(\sigma \left| r_{j}\left( t \right) -r_{j}\left( 0 \right) \right| \geqslant 0.3\), \(\omega =0\), where \(\sigma \) is the average atomic spacing of a particular system and 0.3 is chosen as a typical amplitude of caged particles. The detailed description on the choice of cutoff has been provided elsewhere [11]. The mean-squared variance of \(Q_{s}\left( t \right) \) then defines the (self-part) of \(\chi _{4}\)

Four-point density correlation function as a function of T. a Four-point density correlation function \(\chi _{4}(t)\) (left figure) and its peak value (right figure) for our \(\hbox {Al}_{{90}}~\hbox {Sm}_{{10}}\) metallic GF liquid as a function of T. The peak in \(\chi _{4}(t)\) occurs near the lambda transition temperature \(T_{\lambda }\) at which \(C_{p,}\) exhibits a peak. (See discussion of this T and other characteristic temperatures in SI.) The inset of the left figure directly compares the T variation of \(C_{p,}\) and the peak in \(\chi _{4}\) (t). b Peak in \(\chi _{4}\) as a function of T. For a discussion of this thermodynamic feature in the case of water; see Refs. [95, 96], and [164]

We see in Fig. 21a that \(\chi _{4}(t)\) exhibits a qualitative variation that is similar to the number of particles of high and low mobility and, following the usual convention, we define the time at which \(\chi _{4}(t)\) peaks as being a characteristic time of the material. As in the case of \(C_{p}\), we see that this response function peaks around 750 K, which is again in the vicinity of the lambda transition temperature \(T_{\lambda }\) defined above.

The temperature derivative of the density \(d\rho / \textit{dT}\), or more specifically, -(\(d\rho / \textit{dT}) / \rho \) defines the thermal expansion coefficient, and we see in Fig. 22a that this quantity also has a peak near \(T_{\lambda }\). The density \(\rho \) as a function of T, shown in the insert to Fig. 22a, correspondingly has a kink near this characteristic temperature, a thermodynamic feature characteristic of fluids exhibiting equilibrium polymerization. The weak nature of these singular features is characteristic of highly rounded thermodynamic transitions, [40, 161,162,163] as one finds in the Ising model with a strong applied magnetic field. For completeness, we also calculate the isothermal compressibility,

as function of T where V is the volume of the system and \(< \ldots>\) denotes NPT ensemble average. This response function likewise has a peak near \(T_{\lambda }\), but the strength of this feature is rather weak, and, moreover, when we combine \(\kappa \) and \(\rho \) to estimate structure factor in the long wavelength limit, \(S(0) = \rho \kappa \hbox {k}_{\mathrm{B}} T\), we find (results not shown) only a smoothly varying function of T having an inflection point near \(T_{\lambda }\). The osmotic compressibility of solutions exhibiting equilibrium polymerization correspondingly exhibits a sigmoidal variation with T [161]. We finally remark that all these thermodynamic response functions exhibit singular features that are much stronger in the case of supercooled water, although observations of these transitions in real bulk water are made difficult by the strong tendency of water to crystallize near the T where measurements of confined water and simulations indicate a peak in the specific heat and the other response functions discussed above [95, 96]. We next provide a tentative physical explanation of the observed growth of dynamic heterogeneity in GF liquids and associated thermodynamic properties just described based on established models of the thermodynamics of materials composed of associating particles.

Observation of thermodynamic signatures in the temperature dependence of the density and compressibility. a Temperature derivative of the density \(\rho \) or thermal expansion coefficient for our \(\hbox {Al}_{{90}}~\hbox {Sm}_{{10}}\) metallic GF liquid as a function of T. b Isothermal compressibility for our \(\hbox {Al}_{{90}}~\hbox {Sm}_{{10}}\) metallic GF liquid materials as a function of T. Notice the similarity of the kink in the density near \(T_{\lambda }\) to a feature observed by Fox and Flory\(^{1}\) in the density of polystyrene melts at a Tlater identified as the ‘liquid–liquid’ transition temperature.\(^{9}\)

Douglas and coworkers [1, 16, 97, 160] have previously argued that glass formation can viewed generally as a particular kind of supramolecular assembly transition in the formation of the form of dynamic polymers, i.e., strings. This should not be surprising since many second order phase transitions [equilibrium polymerization, Ising model, XY model, Heisenberg model, spherical model] can be formulated in terms polymerization transitions with different weights on the self-interactions of clusters describing correlations in these systems [169,170,171], and Douglas and Ishinabe [172] used this formal theoretical framework to estimate the critical temperatures of this important class of spin models based on geometrical information about self-avoiding paths. Moreover, the problems of thermal initiation of equilibrium polymers or activated polymerization as in the polymerization of actin and sulfur upon change of temperature can be formulated in terms of an Ising model with an applied magnetic field to model the initiator or activation processes regulating the polymerization process [173, 174]. Quite apart from this abstract perspective, we actually see dynamic structures in our simulations of ordinary GF liquids (both metallic glasses and polymeric), consistent with activated equilibrium polymerization. This point of view has been discussed in previous papers aimed at understanding ordinary glass formation [1, 16, 97, 160], and here we consider if this type of treatment with the present metallic GF material.

We note at the outset that the observation of sharp features in thermodynamic response functions such as the specific heat, density and osmotic compressibility are characteristic of equilibrium polymerization transitions that are highly cooperative, [161] as in the well-known case of the equilibrium polymerization of sulfur, where a lambda transition, again defined by a peak in \(C_{p}\) [57]. Exactly solvable models show that sharpness of the rounded polymerization transition [40, 162] when varying temperature and the magnitude of the \(C_{p}\) peak can be tuned over a wide range by varying the initiator concentration, rate of activation or other physical processes that initiate the polymerization process. [163] Douglas and coworkers [161] suggest that the degree of cooperativity of this class of transitions is directly related to the extent that the assembly process resembles (in a precise fashion) a phase transition. It thus seems very likely that this perspective might encompass glass formation of the ordinary type glass formation for which the transition is highly rounded and the equilibrium specific heat feature is not apparent to highly cooperative types of glass formation for which strong thermodynamic anomalies are apparent at characteristic temperatures to define the transition. In SI, we provide detailed description and discussion on how we determine the characteristic temperatures of glass formation (\(T_{o}, T_\mathrm{g}, T_{c}, T_\mathrm{A}\)), the lambda transition temperature, \(T_{\lambda }\), the fragile–strong transition temperature, \(T_{\mathrm{FS}}\), and the bifurcation temperature, \(T_{\alpha \beta }\). It is also characteristic of this type off rounded thermodynamic transition that there is definite onset temperature where the association begins appreciably and where the transition saturates after the structures have fully formed after sufficient cooling. It is also notable that the inverse scaling between the average size of the exponentially distributed polymer structures can be derived to scale inversely to the configurational entropy of the fluid [162], as AG assumed heuristically.

One of the most basic properties to consider in the equilibrium polymerization is the fraction of the particles that are in an assembled polymeric state of all particles that are free to possibly associate. This is the order parameter of the self-assembly process, and we may determine this order parameter for the string assembly process discussed above. In Fig. 23, we show the fraction of mobile particles that are organized into the string state, \(\Phi \). We observe that the onset temperature \(T_\mathrm{A}\) is close to the T at which \(\Phi \) starts to increase upon cooling, the peak of \(\hbox {d}\Phi / \hbox {d}T\) defining the locus of the polymerization transition [161] is close to \(T_{\lambda }\), where the specific heat transition occurs in both the polymerization model and our metallic glass simulations and the ‘saturation temperature’ [160] where the self-assembly transition is over around 450 K. In the polymerization model, the saturation temperature corresponds to a T at which the configurational entropy of the fluid associated with the self-assembly process starts to flatten off as the assembled structures become completely organized and we are tempted to call this a thermodynamic ‘glass transition temperature’ \(T_\mathrm{g}\) since there is phenomenological evidence that the fluid configurational entropy in GF liquids becomes slowly varying below the calorimetric \(T_\mathrm{g}\) of measurements under cooling conditions where a very slow cooling rate is employed. The significance of this \(T_\mathrm{g}\) in the self-assembly model is that the self-assembly transition is simply ‘over’ at this point. All these characteristic temperatures of the FS glass formation process are reflected directly in the differential change of the activation energy \(E_\mathrm{diff}\) in Fig. 1b and the T dependence of the ‘polymerization order parameter’ \(\Phi \) resembles the T dependence of the true activation energy in Fig. 1a. We note that Tanaka and coworkers [96] have introduced a two-state model of water, which is similar in spirit to the polymerization model, except this model does not consider the spatial correlation between ‘ordered’ species. In this model, the fraction of particles converted to a thermodynamically favored state of different mobility which plays a key role in their modeling of the activation free energy. Douglas et al. [161] have shown this type of two state model serves as an approximation to more complex supramolecular association models (the state of the mobile particles be considered in abstract sense to be either in a polymerized or unpolymerized state if you have no concern about the cluster connectivity) for the purposes of estimating \(\Phi \). Cooperativity in this simple type of kinetic model can be tuned by formally changing the order of this reaction to match the cooperativity exhibited by polymerization process involving a chain of reactions involved in forming the polymer [161]. Our main point here is that modeling of Tanaka and coworkers of the dynamics and thermodynamics of water [96] can be considered to be very much in the same spirit as the equilibrium polymerization model, and this approach likewise leads to anomalies in the thermodynamic response functions, as seen in the simulations of both water and our own simulations. We expect the more complex polymerization model to become more useful when subjecting fluids to flow or amorphous solids to deformation where the deformation will interact and alter the structure of the self-assembled clusters, thereby influencing the dynamics of the GF material [2].

String order parameter as a function of T. Order parameter \(\Phi \) for the polymerization of clusters of chains exhibiting string-like collective motion for our \(\hbox {Al}_{{90}}~\hbox {Sm}_{{10}}\) metallic GF liquid as a function of T. We also plot the derivative \(\Phi \), where we notice the similarity of these quantities to the variation of the activation energy in Fig. 1a and the derivative \(\hbox {d}\Phi / \hbox {dT}\) to the differential activation energy in Fig. 1b

We mention that the activation free energy was found previously to vary sigmoidally with T, as we have found in the present metallic glass material, when fit our simulation data for the segmental relaxation dynamics for a coarse-grained polymer melts quantitatively to the string model with an initiated equilibrium polymerization [1, 16]. Notably, the polymer melt exhibited the conventional pattern of glass formation discussed above [16] and thus did not exhibit a FS transition. The difference between this conventional polymeric glass-forming liquid and the present metallic glass-forming liquid is the broadness of the transition. When the glass transition is much broader, the relaxation time grows so much during the course of cooling that the system just can’t complete the thermodynamic crossover between the high and low T Arrhenius regimes because of a non-equilibrium structural arrest. The relatively rapid rate at which systems exhibiting a FS type glass formation ‘complete’ the thermodynamic transition allows the full sigmoidal variation of the activation energy to be observed. We think that variations in the degree of cooperativity of the glass transition then accounts for the different classes of GF liquids and that all GF liquids should be describable in terms of a unified self-assembly based description in which the source of this variable cooperativity is addressed. This remains to be seen, but this point of view of glass formation liquids looks promising.

Appendix C: equilibrium polymerization, liquid–liquid transition and glass formation

We mention that the idea that equilibrium polymerization underlies glass formation can be traced back to the earliest modeling of GF liquids. In 1934, Hägg [175] responded to Zachariasen’s introduction of random network model of glasses [176] by suggesting that both metallic and inorganic glasses involved the formation of one-dimensional chains (or two-dimensional sheet polymers or highly perforated sheets, i.e., branched polymers [110]) often composed tetrahedra in ion complexes or arising from bonding habits of low coordination in ‘metalloid’ elements such as the chalcogenides, first forming well into the liquid state, but growing progressively upon cooling, thereby frustrating crystallization because of difficulty of molecular species localized in clusters to diffuse and by the ‘muddle of other chains’ that further inhibit cluster movement, i.e., entanglement. Apart from the prescience of this model of glass formation, it was remarkable given that the concept of polymers was hardly accepted at this time. After a heated exchange between Zachariasen and Hägg, [177, 178], Hägg’s model regrettably sank into oblivion, until recently, where measurement have largely confirmed his original conception of a specific form and origin of a specific form of dynamic heterogeneity found in many GF liquids.

The polymerization model of glass formation, in which the ‘ordering’ process in many GF liquids is viewed as a form of equilibrium polymerization [97, 160], also has strong implications for the miscibility of metal alloys and other multicomponent glass-forming liquids since polymerization inherently alters the miscibility of mixtures and can lead to a multiplicity of critical points arising from competition of the polymerization thermodynamics and phase separation [163, 179, 180] [See Figs. 6a and b and Ref. [163]] and the change in miscibility due to this physical cause is particularly significant when one of the components self-assembles upon heating, as in the case of S. This type of additive is predicted [181] to give rise to closed loop phase behavior, as observed in S-Te mixtures. [182,183,184,185] This type of phase behavior is well known, and Tsuchiya [179] recognized the relevance of this type of ‘structural change’ in liquid mixtures on the thermodynamic stability of Te alloys. This phenomenon has been well-studied in related problem S solutions [57] (See Fig. 1a of Ref. [57]) and in the phase diagram of \(\hbox {He}^{3}\)-\(\hbox {He}^{4}\) mixtures [186, 187], systems which are also mentioned by Tsuchiya. [179] Note that the liquid–liquid transition between the normal and superfluid liquid states occurs as a line of second-order phase transitions emanating from the critical point in the He mixtures can be viewed as a polymerization line based on Feynman’s equilibrium polymerization model of the superfluid transition where the polymers were assumed to move collectively in permutational motion having the form of polydisperse polymer rings. [188, 189] We will see this type of permutational motion in connection with the classical molecular dynamics of our Al–Sm metallic GF liquid. This type of phase behavior, involving a line of polymerization or self-assembly line of transitions that terminates near the critical point of the phase boundary for liquid–liquid phase separation, is ubiquitous in complex fluids in which molecular assembly occurs, micelle formation [190, 191], living polymers [57], thermally reversible gelation of polymers in solution [192, 193], etc. Liquid–liquid thermodynamic transitions, accompanied by significant changes in fluid structure and viscoelastic properties in the two liquid states, are thus very common in complex fluids, even if this phenomenon is not always overtly recognized. In our companion paper focusing on the fast dynamics of our Al–Sm metallic glass [4], we observe clear evidence of density fluctuations at a nanoscale, providing some evidence of a liquid–liquid phase separation of the metallic glass into two distinct density states. Our observations accord with the findings of the combined experimental and computational study of \(\hbox {Cu}_{{64}}\hbox {Zr}_{{36}}\) metallic glasses by Feng et al. [194]

From a practical standpoint, we note that FS glass formation plays an essential role in the practical performance of phase-change memory materials (compounded from Te and other chalcogenides and group-IV and group-V elements [195] to which the chalcogenides strongly bind) because it allows for rapid switching between crystalline and amorphous states in connection with the speed of data recording, in addition to ‘non-volatility’ of stored information [196, 197] because of the ultrastable nature of this class of materials in their glass state [46, 198]. The accompanying large changes in conductivity and other properties accompanying this structural transition also explain the strong attraction of these materials for applications. In the metallic glass context, this structural transition is accompanied by a significant increase (\(\approx 20 \%\)) of the hardness of the material [46, 199]. Extensive evidence is found for liquid–liquid phase separation in chalcogenide-based phase-change materials [200]. Particularly informative measurements of the singular variation of \(C_{p}\) and other response functions for Te and alloys with other chalcogenide atomic species have been described by Tsuchiya [64, 65]. Recent first principle quantum mechanical calculations for cooled water [201] have also indicated the formation dynamic polymeric water clusters that are rather reminiscent of those just described in metallic systems, so it is not surprising that all these systems exhibit FS type of glass formation accompanying this type of structural organization process. Kanno et al. [202] have drawn a strong analogy between the structural transformation and the associated lambda transition temperature in chalcogenides and the thermodynamic anomalies of water.

Rights and permissions

About this article

Cite this article

Zhang, H., Wang, X., Yu, HB. et al. Dynamic heterogeneity, cooperative motion, and Johari–Goldstein \(\beta \)-relaxation in a metallic glass-forming material exhibiting a fragile-to-strong transition. Eur. Phys. J. E 44, 56 (2021). https://doi.org/10.1140/epje/s10189-021-00060-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epje/s10189-021-00060-7