Abstract

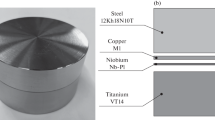

We investigate the influence of heat treatment on the residual stress formation in the 7-mm-thick three-layer wear-resistant bimetal steel 60–steel 15–steel 60 sheet produced by hot rolling. We determine that the thickness of the cladding layers is ≈2–2.1 mm, the thickness of the main layer is ≈2.8–3 mm, and the transition zone width is ≈0.5–0.8 mm. We show that the most favorable distribution of the residual stresses and the set of mechanical properties will achieved after quenching and tempering at 300°C.

Similar content being viewed by others

REFERENCES

Rodionova, I.G., et al., Korrozionnostoikie bimetally s prochnym stsepleniem sloev dlya neftekhimicheskoi promyshlennosti i drugikh otraslei (Corrosion-Resistant Bimetals with Strong Adhesion of Layers for the Petrochemical and Other Industries), Moscow: Metallurgizdat, 2011.

Bykov, A.A., Development of bimetal production, Metallurg, 2009, no. 9, pp. 61–64.

Sirotenko, L.D., Shlykov, E.S., and Ablyaz, T.R., Use of bimetallic materials in mahcine engineering, Sovrem. Probl. Nauki Obraz., 2015, no. 2, p. 163.

Sakhtemanian, M.R., Honarpisheh, M., and Amini, S., A novel material modeling technique in the single-point incremental forming assisted by the ultrasonic vibration of low carbon steel/commercially pure titanium bimetal sheet, Int. J. Adv. Manuf. Technol., 2019, vol. 102, nos. 1–4, pp. 473–486.

Trykov, Yu.P., shmorgun, V.G., Slautin, O.V., abramenko, S.A., and Dontsov, D.Yu., Growth kinetics of a diffusion layer in copper-aluminum composites, Materialovedenie, 2009, no. 1, pp. 24–28.

Shelyakov, A.V., Glezer, A.M., Fedotov, V.T., Roesner, H., and Wilde, G., Structural features of composite materials produced by melt quenching, Inorg. Mater.: Appl. Res., 2011, vol. 2, no. 1, pp. 81–84.

Kolmakov, A.G., Study of the structure, plastic deformation, and fracture of metals using a system approach, Russ. Metall. (Engl. Transl.), 2004, vol. 2004, no. 4, pp. 384–391.

Nasakina, E.O., Baikin, A.S., Sergienko, K.V., Leonov, A. V., Kaplan, M.A., Seryogin, A.V., Myasnikova, N.V., Sevostyanov, M.A., Kolmakov, A.G., and Simakov, S.V., Formation and investigation of composite material silver–nitinol for medical purposes, Inorg. Mater.: Appl. Res., 2017, vol. 8, no. 1, pp. 112–117.

Kolmakov, A.G., Gerov, V.V., Baranov, E.E., Krasnobaev, N.N., and Terent’ev, V.F., Effect of a magnetron 12Kh18N10T steel coating on the deformation and fracture of maraging steel during static tension, Deform. Razrushenie Mater., 2006, no. 1, pp. 21–28.

Shin, J., Kim, T., Lim, K., Cho, H., Yang, D., Jeong, C., and Yi, S., Effects of steel type and sandblasting pretreatment on the solid-liquid com pound casting characteristics of zinc-coated steel/aluminum bimetals, J. Alloys Compd., 2019, vol. 778, pp. 170–185.

Sevost’yanov, M.A., Kolmakov, A.G., Molokanov, V.V., Zabolotnyi, V.T., Umnov, P.P., and Kurakova, N.V., Deformation and fracture of a composite material based on a high-strength maraging steel covered with a melt-quenched Co69Fe4Cr4Si12B11 alloy layer, Russ. Metall. (Engl. Transl.), 2011, vol. 2011, no. 4, pp. 337–344.

Barannikova, S.A., Li, Yu.V., Lunev, A.G., Shlyakhova, G.V., and Zuev, L.B., Structure and plastic flow heterogeneities of the 12Kh18N9T steel–St3 steel bimetal during tension, Russ. Metall. (Engl. Transl.), 2018, vol. 2018, no. 4, pp. 383–388.

Li, Z., Zhao, J., Wu, H., Jiao, S., and Jiang, Z., Experimental investigation on the mechanical and tribological coupled behaviour of bimetal composite under different states, Surf. Topogr.: Metrol. Prop., 2019, vol. 7, no. 2, art. ID 025015.

Khlybov, A.A. and Ryabov, D.A., Assessment of residual stresses in specimens of ferritic-pearlitic steel with austenitic cladding, Met. Sci. Heat Treat., 2019, vol. 61, nos. 1–2, pp. 114–119.

Li, Z., Zhao, J., Jia, F., Zhang, Q., Liang, X., Jiao, S., and Jiang, Z., Analysis of bending characteristics of bimetal steel composite, Int. J. Mech. Sci., 2018, vol. 148, pp. 272–283.

Sun, B.S., Wang, C.W., and Zhao, Z.L., Research on cold rolling of 41Cr4/20NiCrMo7 bimetal composite bearing ring, Metalurgija, 2018, vol. 57, no. 4, pp. 283–286.

Denisov, I.V., Structure and properties of ‘steel 08kp + ChNMSh iron’ bimetal obtained by explosion welding, Met. Sci. Heat Treat., 2017, vol. 59, no. 1–2, pp. 102–105.

Dorofeyev, Yu.G., Dorofeyev V.Yu., Babets A.V., Bessarabov E.N., Romanova O.N., and Sviridova, A.N., Contact interaction peculiarities at the boundary of layers of structural steel–high-speed steel hot-forged powder bimetal, Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 6, pp. 643–652.

Tan, C., Zhou, K., Ma, W., and Min, L., Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture, Mater. Des., 2018, vol. 155, pp. 77–85.

Sergeev, N.N. and Sergeev, A.N., Mekhanicheskie svoistva i vnutrennee trenie vysokoprochnykh stalei v korozionnykh sredakh (Mechanical Properteis and Internal Friction of High-Strength Steels in Aggressive Media), Tula: Tul’sk. Gos. Univ., 2018.

Doroshev, Yu.F., Rostovtsev, N.M., Solov’ev, V.S., Sergeev, N.N., and Matveeva, N.Ya., Three-layer steel for plow blades, Stal’, 1983, no. 8, pp. 8–11.

Rodionova, I.G., Amezhnov, A.V., Zaitsev, A.I., Pavlov, A.A., Baklanova, O.N., Strizhakova, T.I., Grishin, A.V., and Golovanov, A.V., The effect of the chemical composition of the cladding layer and heat treatment modes on the performance properties of wear-resistant bimetallic materials, Probl. Chern. Metall. Materialoved., 2013, no. 2, pp. 59–65.

Gvozdev, A.E., Sergeyev, N.N., Minayev, I.V., Tikhonova, I.V., and Kolmakov, A.G., Role of nucleation in the development of first-order phase transformations, Inorg. Mater.: Appl. Res., 2015, vol. 6, no. 4, pp. 283–288.

Gvozdev, A.E., Kolmakov, A.G., Kuzovleva, O.V., Sergeev, N.N., and Tikhonova, I.V., Mechanical properties of constructional and tool steels in the pre-transformation state and thermomechanical treatment, Deform. Razrushenie Mater., 2013, no. 11, pp. 39–42.

Gvozdev, A.E., Kolmakov, A.G., Provotorov, D.A., Minaev, I.V., Sergeev, N.N., and Tikhonova, I.V., Grain size effect of austenite on the kinetics of pearlite transformation in low-and medium-carbon low-alloy steels, Materialovedenie, 2014, no. 7, pp. 23–26.

Funding

This work was performed within the framework of the state assignment of the Ministry of Education and Sciences of the Russian Federation, no. 11.6682.2017/8.9 and no. 075-00746-19-00.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest. The authors declare no conflict of interest.

Additional information

Translated by I. Dikhter

Rights and permissions

About this article

Cite this article

Sergeev, N.N., Sergeev, A.N., Kutepov, S.N. et al. Influence of Heat Treatment on Residual Stress Formation in the Wear-Resistant Steel 60–Steel 15–Steel 60 Bimetal Material. Inorg. Mater. Appl. Res. 12, 5–9 (2021). https://doi.org/10.1134/S2075113321010378

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113321010378