Abstract

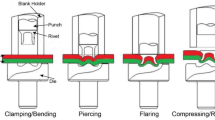

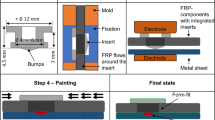

Self-piercing riveting (SPR) is a mature method to join dissimilar materials in vehicle body assembling. Friction self-piercing riveting (F-SPR) is a newly developed technology for joining low-ductility materials by combining SPR and friction stir spot welding processes. In this paper, the SPR and F-SPR were employed to join AA6061-T6 aluminum alloy and AZ31B magnesium alloy. The two processes were studied in parallel to investigate the effects of stack orientation on riveting force, macro-geometrical features, hardness distributions, and mechanical performance of the joints. The results indicate that both processes exhibit a better overall joint quality by riveting from AZ31B to AA6061-T6. Major cracking in the Mg sheet is produced when riveting from AA6061-T6 to AZ31B in the case of SPR, and the cracking is inhibited with the thermal softening effect by friction heat in the case of F-SPR. The F-SPR process requires approximately one-third of the riveting forces of the SPR process but exhibits a maximum of 45.4% and 59.1% higher tensile–shear strength for the stack orientation with AZ31B on top of AA6061-T6 and the opposite direction, respectively, than those of the SPR joints. The stack orientation of riveting from AZ31B to AA6061-T6 renders better cross-section quality and higher tensile–shear strength and is recommended for both processes.

Similar content being viewed by others

Abbreviations

- SPR:

-

Self-piercing riveting

- F-SPR:

-

Friction self-piercing riveting

- FSSW:

-

Friction stir spot welding

References

Min, J., Li, J., Carlson, B.E., Li, Y., Quinn, J.F., Lin, J., Wang, W.: Friction stir blind riveting for joining dissimilar cast Mg AM60 and Al alloy sheets. ASME J. Manuf. Sci. Eng. 137(5), 051022 (2015)

Liu, L., Ren, D., Liu, F.: A review of dissimilar welding techniques for magnesium alloys to aluminum alloys. Materials 7(5), 3735–3757 (2014)

Moraes, J.F., Jordon, J.B., Su, X., Brewer, L.N., Fay, B.J., Bunn, J.R., Sochalski-Kolbus, L., Barkey, M.E.: Residual stresses and plastic deformation in self-pierce riveting of dissimilar aluminum-to-magnesium alloys. SAE Int. J. Mater. Manuf. 11(2), 139–150 (2018)

Park, J., Kim, J., Park, N., Kim, Y.: Study of forming limit for rotational incremental sheet forming of magnesium alloy sheet. Metall. Mater. Trans. A 41(1), 97–105 (2009)

Li, D., Chrysanthou, A., Patel, I., Williams, G.: Self-piercing riveting—a review. Int. J. Adv. Manuf. Technol. 92(5–8), 1777–1824 (2017)

Durandet, Y., Deam, R., Beer, A., Song, W., Blacket, S.: Laser assisted self-pierce riveting of AZ31 magnesium alloy strips. Mater. Des. 31(Suppl 1), S13–S16 (2010)

Easton, M., Beer, A., Barnett, M., Davies, C., Dunlop, G., Durandet, Y., Blacket, S., Hilditch, T., Beggs, P.: Magnesium alloy applications in automotive structures. JOM 60(11), 57–62 (2008)

Aoyagi, N., Karasawa, T., Miyashita, Y., Kamado, S.: Joining strength ofAM50 magnesium alloy sheet jointed by in situ heating self pierce riveting process. J. Jpn. Inst. Light Met. 62(6), 237–243 (2012)

Hahn, O., Horstmann, M.: Mechanical joining of magnesium components by means of inductive heating-realization and capability. Mater. Sci. Forum 539, 1638–1643 (2007)

Li, Y., Wei, Z., Wang, Z., Li, Y.: Friction self-piercing riveting of aluminum alloy AA6061-T6 to magnesium alloy AZ31B. ASME J. Manuf. Sci. Eng. 135(6), 061007 (2013)

Ma, Y., He, G., Lou, M., Li, Y., Lin, Z.: Effects of process parameters on crack inhibition and mechanical interlocking in friction self-piercing riveting of aluminum alloy and magnesium alloy. ASME J. Manuf. Sci. Eng. 140(10), 101015 (2018)

Ma, Y., Lou, M., Li, Y., Lin, Z.: Modeling and experimental validation of friction self-piercing riveted aluminum alloy to magnesium alloy. Weld. World 62(6), 1195–1206 (2018)

Ma, Y.W., Li, Y.B., Lin, Z.Q.: Joint formation and mechanical performance of friction self-piercing riveted aluminum alloy AA7075-T6 joints. ASME J. Manuf. Sci. Eng. 141(4), 041005 (2019)

Lim, Y.C., Warren, C.D., Chen, J., Feng, Z.: Joining of lightweight dissimilar materials by friction self-piercing riveting. In: Friction Stir Welding and Processing X, pp. 189–195. Springer, Cham (2019)

Liu, X., Lim, Y.C., Li, Y., Tang, W., Ma, Y., Feng, Z., Ni, J.: Effects of process parameters on friction self-piercing riveting of dissimilar materials. J. Mater. Process. Technol. 237, 19–30 (2016)

Ma, Y., Yang, B., Lou, M., Li, Y., Ma, N.: Effect of mechanical and solid-state joining characteristics on tensile–shear performance of friction self-piercing riveted aluminum alloy AA7075-T6 joints. J. Mater. Process. Technol. 278, 116543 (2020)

Chai, P., Hu, W., Ji, S., Ai, X., Lv, Z., Song, Q.: Refill friction stir spot welding dissimilar Al/Mg alloys. Alloys J. Mater. Eng. Perform. 28(10), 6174–6181 (2019)

Feng, X.S., Li, S.B., Tang, L.N., Wang, H.M.: Refill friction stir spot welding of similar and dissimilar alloys: a review. Acta Metall. Sin. 33(1), 30–42 (2019)

Dong, Z., Song, Q., Ai, X., Lv, Z.: Effect of joining time on intermetallic compound thickness and mechanical properties of refill friction stir spot welded dissimilar Al/Mg alloys. J. Manuf. Process. 42, 106–112 (2019)

Porcaro, R., Hanssen, A.G., Langseth, M., Aalberg, A.: The behaviour of a self-piercing riveted connection under quasi-static loading conditions. Int. J. Solids Struct. 43(17), 5110–5131 (2006)

Lou, M., Li, Y., Li, Y., Chen, G.: Behavior and quality evaluation of electroplastic self-piercing riveting of aluminum alloy and advanced high strength steel. ASME J. Manuf. Sci. Eng. 135(1), 011005 (2013)

Madasamy, C., Faruque, O., Tyan, T., Thomas, R.: Static and impact behavior of self-pierced rivet connections in aluminum. ASME Appl. Mech. 250, 73–80 (2001)

Abe, Y., Kato, T., Mori, K.: Self-piercing riveting of high tensile strength steel and aluminium alloy sheets using conventional rivet and die. J. Mater. Process. Technol. 209(8), 3914–3922 (2009)

Zhang, X., He, X., Xing, B., Wei, W., Lu, J.: Quasi-static and fatigue characteristics of self-piercing riveted joints in dissimilar aluminium-lithium alloy and titanium sheets. J. Mater. Res. Technol. 9(3), 5699–5711 (2020)

Sun, X., Khaleel, M.A.: Strength estimation of self-piercing rivets using lower bound limit load analysis. Sci. Technol. Weld. Join. 10(5), 624–635 (2013)

Mori, K., Abe, Y., Kato, T.: Self-pierce riveting of multiple steel and aluminium alloy sheets. J. Mater. Process. Technol. 214(10), 2002–2008 (2014)

Zhang, H.: Influence of riveting sequence/direction on distortion of steel and aluminum sheets. J. Manuf. Process. 53, 304–309 (2020)

General Motors: Self piercing rivets, engineering standards-material specification metals GMN11010. North American engineering standards (2004)

Li, D., Han, L., Chrysanthou, A., Shergold, M., Williams, G.: The effect of setting velocity on the static and fatigue strengths of self-piercing riveted joints for automotive applications. In: TMS 143rd Annual Meeting and Exhibition, Springer, Cham (2014)

Li, Y., Ma, Y., Lou, M., Lin, Z.: Rivet for friction self-piercing riveting and friction self-piercing riveting connection system thereof. US Patent 16/068,637, 7 Feb 2019

Acknowledgements

The authors would like to acknowledge the financial support of the National Key Research and Development Program of China (Grant No. 2016YFB0101606-8) and the National Natural Science Foundation of China (Grant Nos. U1564204, U1764251, and 51322504).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ma, Y., Niu, S., Shan, H. et al. Impact of Stack Orientation on Self-Piercing Riveted and Friction Self-Piercing Riveted Aluminum Alloy and Magnesium Alloy Joints. Automot. Innov. 3, 242–249 (2020). https://doi.org/10.1007/s42154-020-00108-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42154-020-00108-y