Abstract

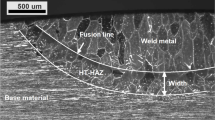

The influence of heat input and multiple welding cycles on the microstructure of the heat-affected zone in autogenously TIG-welded 6 mm 2507 type super duplex stainless steel plates was investigated. In order to produce multiple thermal cycles, one to four pass bead-on-plate welds were made with arc energies of 0.47 and 1.08 kJ/mm, corresponding to heat inputs of 0.37 and 0.87 kJ/mm. Several thermocouples were attached to record thermal cycles on the front and back sides of the plates. Finite element modelling was successfully done to map and correlate measured and calculated peak temperatures. Only minor changes were seen in the ferrite content at 1 and 2 mm from the fusion boundary. Nitrides formed in all passes of the low heat input samples in a region next to the fusion boundary, but only after the third and fourth passes of the high heat input samples. Sigma phase precipitated only in a zone heated to a peak temperature in the range of approximately 828 to 1028 °C. Multiple reheating was found to promote precipitation of sigma phase relatively more than slower cooling. A precipitation free zone was observed between the nitride and sigma phase bands. The precipitation behaviour could be understood from equilibrium phase diagrams, evaluation of local thermal cycles and by correlating results from the modelling and measurements of peak temperatures. It is suggested that the peak temperature, the accumulated time in the critical temperature range between approximately 828 and 1028 °C, and the number of thermal cycles are the most relevant criteria when evaluating the risk of sigma phase formation.

Similar content being viewed by others

References

Gunn RN (1997) Duplex stainless steels: microstructure, properties and applications. Woodhead Publishing

Tan H, Jiang Y, Deng B, Sun T, Xu J, Li J (2009) Effect of annealing temperature on the pitting corrosion resistance of super duplex stainless steel UNS S32750. Mater Charact 60(9):1049–1054

Karlsson L (1995) Welding duplex and super duplex stainless steels. Anti-Corros Methods Mater 42(6):30–35

Pohl M, Storz O, Glogowski T (2007) Effect of intermetallic precipitations on the properties of duplex stainless steel. Mater Charact 58(1):65–71

Nilsson J-O (1992) Super duplex stainless steels. Mater Sci Technol 8(8):685–700

Pettersson N, Pettersson RF, Wessman S (2015) Precipitation of Chromium Nitrides in the Super Duplex Stainless Steel 2507. Metall Mater Trans A 46(3):1062–1072

Taban E, Kaluc E (2011) Welding behaviour of Duplex and Superduplex Stainless Steels using Laser and Plasma ARC Welding processes. Weld World 55(7–8):48–57

Karlsson L, Tolling J Experiences and New Possibilities in Welding Duplex Stainless Steels. IIW Regional Congress on Welding and Related Inspection Technologies,, South Africa, 2006

Wang H-S (2005) Effect of welding variables on cooling rate and pitting corrosion resistance in super duplex stainless weldments. Mater Trans 46(3):593–601

Atamert S, King J (1992) Super duplex stainless steels part 1 heat affected zone microstructures. Mater Sci Technol 8(10):896–912

Nishimoto K, Saida K, Katsuyama O (2006) Prediction of Sigma Phase Precipitation in Super Duplex Stainless Steel Weldments. Weld World 50(3–4):13–28

Tao RL, Liu J, Fan GW, Chang X. The study on welding HAZ microstructure of SAF 2507 Duplex stainless steel by simulation tests. Conf. processdings: Materials Science Forum, 2015. Trans Tech Publ, pp 277–280

Attarha M, Sattari-Far I (2011) Study on welding temperature distribution in thin welded plates through experimental measurements and finite element simulation. J Mater Process Technol 211(4):688–694

Alexandrov B, Lippold J (2006) In-situ weld metal continuous cooling transformation diagrams. Weld World 50(9–10):65–74

Karlsson (2012) Welding Duplex Stainless Steels — A Review Of Current Recommendations. Weld World 56(5–6):65–76. doi:10.1007/BF03321351

Nilsson J, Wilson A (1993) Influence of isothermal phase transformations on toughness and pitting corrosion of super duplex stainless steel SAF 2507. Mater Sci Technol 9(7):545–554

Kim Y-J, Chumbley LS, Gleeson B (2008) Continuous Cooling Transformation in Cast Duplex Stainless Steels CD3MN and CD3MWCuN. J Mater Eng Perform 17(2):234–239

Hurtig K, Choquet I, Scotti A, L.E. Svensson A critical analysis of weld heat input measurement with a water-cooled stationary anode calorimeter. Conf. proceedings: JOM 18, Helsingør, Denmark.

ASTM International (2014) Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels. ASTM A262-14. West Conshohocken, PA

Stenbacka N, Choquet I, Hurtig K Review of arc efficiency values for gas tungsten arc welding. In: IIW Commission IV-XII-SG212, Intermediate Meeting, BAM, Berlin, Germany, 18–20 April, 2012, 2012. pp 1–21

ASTM E1245-03, Standard Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis (2008). ASTM International, West Conshohocken, PA

Taban E (2008) Toughness and microstructural analysis of superduplex stainless steel joined by plasma arc welding. J Mater Sci 43(12):4309–4315

Westin EM, Keehan E, Ström M, Von Brömssen B Laser welding of a lean duplex stainless steel. In: 26th International Congress on Applications of Lasers and Electro-Optics, ICALEO 2007: Congress Proceedings, 2007. pp 335–344

Karlsson L (2013) Welding duplex and super duplex stainless steels., Anti-Corrosion Methods and Materials

Meyer A, Du Toit M (2008) The influence of interstitial diffusion across the fusion line on the HAZ microstructure and properties in 12% chromium type 1.4003 steels. Weld World 52(11–12):42–49

Karlsson L, Pak S (1995) Influence of intermetallic phases on the corrosion properties of duplex stainless steel weld metals. Weld Int 9(7):554–562

Karlsson L (1999) Intermetallic phase precipitation in duplex stainless steels and weld metals: metallurgy, influence on properties, welding and testing aspects. Weld Res Counc Bull 438

Hertzman S, Brolund B, Ferreira PJ (1997) An experimental and theoretical study of heat-affected zone austenite reformation in three duplex stainless steels. Metall Mater Trans A 28(2):277–285

Acknowledgments

The authors would like to thank Sten Wessman from Swerea KIMAB AB and University West for his valuable comments. The great support received from the project partners and their representatives: Joakim Wahlsten (Swerea KIMAB AB, Kista), Rachel Pettersson (Jernkontoret, Stockholm), Hans Åström (ELGA AB, Partille), Lars-Åke Bylund (voestalpine Böhler Welding Nordic AB, Avesta), Henrik Larsson (Thermo-Calc Software AB, Stockholm), Alexander Thulin (Outokumpu Stainless AB, Avesta) and Massimo Cocco (Forsmarks Kraftgrupp AB, Forsmark) is acknowledged. Financial support of the KK foundation for the DuplexWeld project is appreciatively acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Hosseini, V.A., Valiente Bermejo, M.A., Gårdstam, J. et al. Influence of multiple thermal cycles on microstructure of heat-affected zone in TIG-welded super duplex stainless steel. Weld World 60, 233–245 (2016). https://doi.org/10.1007/s40194-016-0300-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0300-5