Abstract

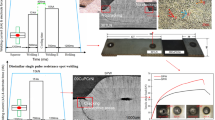

The purpose of this work is to develop hot-wire laser welding for narrow-gap joints. Test pieces of ASTM A 304 stainless steel with a gap width of 3 mm were used. With welding by tentative filler rod made of Inconel 600 alloy, melting phenomena of the molten pool and the weld bead formation during welding were investigated by in situ observation using a high-speed camera. Variations in the main welding parameters such as wire current, wire feeding position, laser irradiation angle, and wire feeding angle were investigated to determine appropriate conditions. Experiments showed that under the optimum welding conditions, hot-wire laser welding was able to produce complete weld deposition with very low dilution of the base metal. An experiment on laser beam reflection indicated that the laser beam reflected from the molten pool was a crucial phenomenon to explain the formation of the weld bead, especially in terms of melting the side groove wall of the base metal. Welding parameters as mentioned above significantly affected weld quality. Furthermore, in the case of welding with filler wire ER NiCrCoMo-1, the Vickers hardness distribution along the transverse welding direction was examined to evaluate weld properties and the bonding strength at the fusion interface was examined in a tensile test, and the results showed that there was no great difference in the hardness profile throughout the cross section of the weld plate. Additionally, metallurgical examination of the fracture surface revealed the rupture occurred at the weld metal, probably because the bonding at the fusion interface was stronger than the weld metal. Therefore, the development of laser welding with hot wire can advance the multi-pass weld for an ultra-narrow-gap joint.

Similar content being viewed by others

References

American Welding Society (2001) Welding hand book, vol. 1. Welding Science and technology, 9th edn. American Welding Society, Doral

Kou S (2003) Welding Metallutgy, 2nd edn. Wiley, New York

Pankaj Biswas, Mandal NR, Parameswaran Vasu, Padasalag SB (2010) Analysis of welding distortion due to narrow-gap welding of upper port plug. J Fusion Eng Des 85:780–788

Starling CMD, Marques PV, Modenesi PJ (1995) Statistical modelling of narrow-gap GTA welding with magnetic arc oscillation. J Mater Proc Technol 51:37–49

Shinji I, Masatoshi M, Yuji K (2009) Application of narrow gap welding process with high speed rotating arc to box column joints of heavy thick plates. JFE Tech Rep 14:16–21

Yapp D, Blackman SA (2004) Recent developments in high productivity pipeline welding. J Braz Soc Mech Sci Eng 26(1):89–97

Liu C, Zhang JX, Xue CB (2011) Numerical investigation on residual stress distribution and evolution during multi pass narrow gap welding of thick-walled stainless steel pipes. J Fusion Eng Des 5681:1–8

Miikka Karhu, Veli Kujanpää l (2008) Experimental test set-up for studying hot cracking in multi pass laser hybrid welding of thick section austenitic stainless steel. Laser Materials Processing Conference, ICALEO, 535–544

Ono M, Shinbo Y, Yoshitake A, Ohmura M (2002) Development of laser-arc hybrid welding. NKK Tech Rev 86:9–12

Yamamoto M, Shinozaki K, Kadoi K, Fujita D, INOUE T, Fukahori M, Kitahara Y (2010) Development of welding method for wide gap lap joint of steel sheet using laser welding with hot-wire. Trans JWRI 39(2):44–46

Okagaito T, Watanabe H, Shinozaki K, Yamamoto M, Kadoi K, Nishijima A, Phaonaim R (2010) Development of narrow gap hot-wire laser welding process for heat-resistant steel pipe for boiler. Natl Meet Jpn Weld Soc 90(4):200–201 (in Japanese)

Shinozaki K, Yamamoto M, Kadoi K, Tsuchiya S, Watanabe H, Nagashima T (2010) Investigation of narrow gap hot-wire laser welding phenomena. Natl Meet Jpn Weld Soc 87:364–365 (in Japanese)

Shinozaki K, Yamamoto M, Kadoi K, Kurachi S, Nishijima A, Watanabe H, Nagashima T (2010) Development of multi-pass welding technology using narrow gap hot-wire laser welding process for nickel-based superalloys. Natl Meet Jpn Weld Soc 87:366–367 (in Japanese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2373, recommended for publication by Commission IV “Power Beam Processes.”

Rights and permissions

About this article

Cite this article

Phaoniam, R., Shinozaki, K., Yamamoto, M. et al. Development of a highly efficient hot-wire laser hybrid process for narrow-gap welding—welding phenomena and their adequate conditions. Weld World 57, 607–613 (2013). https://doi.org/10.1007/s40194-013-0055-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-013-0055-1