Abstract

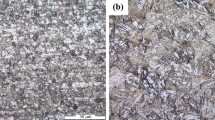

Resistance spot welding of 22MnB5/HSLA350 and its weldability are investigated. From base material to the nugget, the microstructure of 22MnB5 side can be expressed as M/tempered M+ granular carbides/F+M/fine M/lath M, and on HSLA350 side, F+M/F+flocculent P+tempered M/F+flocculent P+M/F+M/lath M are observed. The heat-affected zone (HAZ) of 22MnB5 exhibits obvious softening region and strengthening region caused by the tempered M and quite fine M, respectively. The peak load of welded joints undergoes two stages of a dramatic increase and a subsequent decrease with increases in the welding current. The maximum value (13.82 kN) of peak load is achieved at a welding current of 8 kA. The failure modes involving interfacial failure (IF), pullout failure from the galvanized steel (PFG), pullout failure from boron steel and tearing of the galvanized steel (PFB-TG) and pullout failure from the boron steel (PFB) are discussed in detail.

Similar content being viewed by others

References

Liang, W., Liu, Y., Zhu, B., Zhou, M., and Zhang, Y., “Conduction Heating of Boron Alloyed Steel in Application for Hot Stamping,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 9, pp. 1983–1992, 2015.

Jiang, C., Shan, Z., Zhuang, B., Zhang, M., and Xu, Y., “Hot Stamping Die Design for Vehicle Door Beams using Ultra-High Strength Steel,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 7, pp. 1101–1106, 2012.

Goodarzi, M., Marashi, S., and Pouranvari, M., “Dependence of Overload Performance on Weld Attributes for Resistance Spot Welded Galvanized Low Carbon Steel,” Journal of Materials Processing Technology, Vol. 209, No. 9, pp. 4379–4384, 2009.

Yu, J., “Quality Estimation of Resistance Spot Weld based on Logistic Regression Analysis of Welding Power Signal,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 13, pp. 2655–2663, 2015.

Jong, Y.-S., Lee, Y.-K., Kim, D.-C., Kang, M.-J., Hwang, I.-S., and Lee, W.-B., “Microstructural Evolution and Mechanical Properties of Resistance Spot Welded Ultra High Strength Steel Containing Boron,” Materials Transactions, Vol. 52, No. 6, pp. 1330–1333, 2011.

Zhang, H., Qiu, X., Bai, Y., Xing, F., Yu, H., and Shi, Y., “Resistance Spot Welding Macro Characteristics of the Dissimilar Thickness Dual Phase Steels,” Materials & Design, Vol. 63, pp. 151–158, 2014.

Han, Z. and Indacochea, J., “Effects of Expulsion in Spot Welding of Cold Rolled Sheet Steels,” Journal of Materials Engineering and Performance, Vol. 2, No. 3, pp. 437–444, 1993.

Marashi, S. P. H., Pouranvari, M., Salehi, M., Abedi, A., and Kaviani, S., “Overload Failure Behaviour of Dissimilar Thickness Resistance Spot Welds during Tensile Shear Test,” Materials Science and Technology, Vol. 26, No. 10, pp. 1220–1225, 2010.

Wei, S. T., Lv, D., Liu, R. D., Lin, L., Xu, R. J., et al., “Similar and Dissimilar Resistance Spot Welding of Advanced High Strength Steels: Welding and Heat Treatment Procedures, Structure and Mechanical Properties,” Science and Technology of Welding and Joining, Vol. 19, No. 5, pp. 427–435, 2014.

Zhang, H., Wei, A., Qiu, X., and Chen, J., “Microstructure and Mechanical Properties of Resistance Spot Welded Dissimilar Thickness DP780/DP600 Dual-Phase Steel Joints,” Materials & Design, Vol. 54, pp. 443–449, 2014.

Choi, H.-S., Park, G.-H., Lim, W.-S., and Kim, B.-m., “Evaluation of Weldability for Resistance Spot Welded Single-Lap Joint between GA780DP and Hot-Stamped 22MnB5 Steel Sheets,” Journal of Mechanical Science and Technology, Vol. 25, No. 6, pp. 1543–1550, 2011.

Pouranvari, M. and Marashi, S., “Failure Mode Transition in AHSS Resistance Spot Welds. Part I. Controlling Factors,” Materials Science and Engineering: A, Vol. 528, No. 29, pp. 8337–8343, 2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, X., Yuan, X., Wang, H. et al. Microstructure, mechanical properties and failure mechanisms of resistance spot welding joints between ultra high strength steel 22MnB5 and galvanized steel HSLA350. Int. J. Precis. Eng. Manuf. 17, 1659–1664 (2016). https://doi.org/10.1007/s12541-016-0192-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0192-8