Abstract

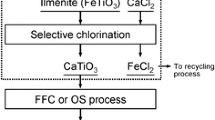

In order to produce high-grade titanium dioxide (95% TiO2) directly from a titanium ore using titanium scrap and iron chloride waste, chlorine recovery and selective chlorination processes were investigated. The mixture of titanium scrap and ferrous chloride in carbon crucible and titanium ore in quartz crucible were placed inside gas-tight quartz tube. The experiments were conducted at 1193–1248 K. Titanium tetrachloride and metallic iron were produced by the chlorination of titanium scrap in the carbon crucible, and the chlorination ratio of titanium chip was 94.6%. In the quartz crucible, 96.2% TiO2 was obtained under certain conditions by the selective removal of iron from the ore because of the reaction with the generated TiCl4. The iron removal ratio of titanium ore was 98.2%. Therefore, the feasibility of the effective use of titanium scrap and iron chloride waste for upgrading titanium ore was demonstrated in this study.

Similar content being viewed by others

References

U.S. Geological Survey, Mineral Commodity Summaries 2016 (U.S. Geological Survey, Virginia, 2016), pp. 178–179

R.G. Becher, R.G. Canning, B.A. Goodheart, S. Uusna, Proc. Aust. Inst. Min. Metall. 21, 21 (1965)

J.H. Chen, L.W. Huntoon, United States Patent 4019898 (1977)

J.H. Chen, United States Patent 3967954 (1976)

J.H. Chen, United States Patent 3825419 (1974)

M. Guéguin, F. Cardarelli, Miner. Process. Extr. Metall. Rev. 28, 1 (2007)

W. Kroll, Trans. Electrochem. Soc. 78, 35 (1940)

M.K. Akhtar, Y. Xiong, S.E. Pratsinis, AIChE J. 37, 1561 (1991)

M.K. Akhtar, S. Vemury, S.E. Pratsinis, AIChE J. 40, 1183 (1994)

T.H. Okabe, J. Kang, The Latest Technological Trend of Rare Metals, ed. by T.H. Okabe, K. Nose (CMC Publishing Co., Ltd., Tokyo, 2012), pp. 83–94

W. Zhang, Z. Zhu, C.Y. Cheng, Hydrometallurgy 108, 177 (2011)

K.I. Rhee, H.Y. Sohn, Metall. Mater. Trans. B 21, 341 (1990)

S. Fukushima, E. Kimura, Titanium · Zirconium, vol: 23 (1975), p. 67

E. Kimura, A. Fuwa, S. Fukushima, Nippon Kogyo Kaishi 95, 18 (1979)

A. Fuwa, E. Kimura, S. Fukushima, Metall. Mater. Trans. B 9, 643 (1978)

K.I. Rhee, H.Y. Sohn, Metall. Mater. Trans. B 21, 321 (1990)

L.K. Doraiswamy, H.C. Bijawat, M.V. Kunte, Chem. Eng. Prog. 55, 80 (1959)

Y. Son, R. Ring, H.-S. Sohn, J. Korean Inst. Resour. Recycl. 25, 74 (2016)

H. Zheng, T.H. Okabe, in Proceedings of 16th Iketani Conference, Masuko Symposium, ed. by S. Yamaguchi. The 16th Iketani Conference Organizing Committee (2006), pp. 1005–1010

R. Matsuoka, T.H. Okabe, in Proceeding Symposium on Metallurgical Technology for Waste Minimization, 134th TMS Annual Meeting (San Francisco, 2005). http://www.okabe.iis.u-tokyo.ac.jp/japanese/for_students/parts/pdf/050218_TMS_proceedings_matsuoka.pdf

J. Kang, T.H. Okabe, Metall. Mater. Trans. B 44B, 516 (2013)

J. Kang, T.H. Okabe, Metall. Mater. Trans. B 48B, 294 (2017)

J. Kang, T.H. Okabe, Mater. Trans. 54, 1444 (2013)

D.F. Othmer, United States Patent 3859077 (1975)

D.F. Othmer, R. Nowak, AIChE J. 18, 217 (1972)

D.F. Othmer, United States Patent 3989510 (1976)

J. Kang, T.H. Okabe, Mater. Trans. 55, 591 (2014)

J. Kang, T.H. Okabe, Int. J. Miner. Process. 149, 111 (2016)

J. Kang, T.H. Okabe, Metall. Mater. Trans. B 47B, 320 (2016)

H. Zheng, T.H. Okabe, J. Alloys Compd. 461, 459 (2008)

Y. Taninouchi, Y. Hamanaka, T.H. Okabe, Mater. Trans. 56, 1 (2015)

Y. Hamanaka, M.Sc. Thesis, (The University of Tokyo, Tokyo, 2015), pp. 139–143

I. Barin, Thermochemical Data of Pure Substances, 3rd edn. (VCH Verlagsgesellschaft mbH, Weinheim, 1995)

J. Kang, T.H. Okabe, Metall. Mater. Trans. B 45B, 1260 (2014)

Acknowledgements

The authors are grateful to Dr. Soo Bok Jeong, Dr. Hanjung Kwon, and Mr. Susumu Kosemura for the supply of samples throughout this study. In addition, the authors thank Ms. Ahram Moon and Ms. Gahee Kim for their technical assistance. Furthermore, the authors are grateful to all the members of the Geoanalysis Department of KIGAM for their technical assistance. This research was partially supported by the Japan Society for the Promotion of Science (JSPS) through a Grant-in-Aid for Scientific Research (S) (KAKENHI Grant No. 26220910) and the Basic Research Project (18-3212) of the Korea Institute of Geoscience and Mineral Resources (KIGAM) funded by the Ministry of Science, ICT and Future Planning of Korea.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kang, J., Moon, G., Kim, MS. et al. Production of High-Grade Titanium Dioxide Directly from Titanium Ore Using Titanium Scrap and Iron Chloride Waste. Met. Mater. Int. 25, 257–267 (2019). https://doi.org/10.1007/s12540-018-0175-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0175-7