Abstract

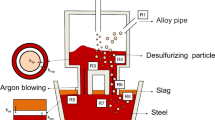

Ruhrstahl–Heraeus (RH) processor is widely applied to the refining process to produce steel with very low carbon contents. In this study, to investigate the effect of ultrasound treatment on RH decarburization process, we have developed two kinds of the water models simulated the RH process and study the removal rate of dissolved oxygen. The one is the RH water model of 1/8 size of actual RH degasser simulated the late-stage of the RH process when surface reaction and plume reaction mainly occur. Through this model, it is found that the ultrasound treatment accelerates dissolved oxygen removal reaction and this tendency is maintained even at low concentrations. Also, the results show that there is a difference in the degassing efficiency depending on the frequencies and the positions of the ultrasonic transducer. Also, to simulate the Early-stage Reaction of the process including the inner-site reaction which is difficult to investigate through the RH water model, the other water model has been developed (the RH-ER water model). This model shows that the ultrasound treatment facilitates the early-stage reaction including inner-site reaction, like the RH water model. These results show that the addition of the ultrasound treatment can accelerate decarburization reaction during RH process compared to conventional process.

Similar content being viewed by others

References

H. Xu, T.T. Meek, Q. Han, Effects of ultrasonic field and vacuum on degassing of molten aluminum alloy. Mater. Lett. 61(4–5), 1246–1250 (2007)

Q. Han, Ultrasonic processing of materials. Metall. Mater. Trans. B 46(4), 1603–1614 (2015)

S.V. Komarov, M. Kuwavara, O.V. Abramov, High power ultrasonics in pyrometallurgy: current status and recent development. ISIJ Int. 45(12), 1765–1782 (2005)

M. Xu, Q. Liu, D. Ma, G. Wu, B. Hu, L. Ma, Effects of ultrasound on the degassing of molten steel in the RH refining process. Steel Res. Int. 85(5), 771–775 (2014)

G.I. Eskin, Cavitation mechanism of ultrasonic melt degassing. Ultrason. Sonochem. 2(2), S137–S141 (1995)

H. Puga, J. Barbosa, E. Seabra, S. Ribeiro, M. Prokic, The influence of processing parameters on the ultrasonic degassing of molten AlSi9Cu3 aluminium alloy. Mater. Lett. 63(9), 806–808 (2009)

R. Haghayeghi, H. Bahai, P. Kapranos, Effect of ultrasonic argon degassing on dissolved hydrogen in aluminium alloy. Mater. Lett. 82, 230–232 (2012)

A. Ramirez, M. Qian, B. Davis, T. Wilks, D.H. StJohn, Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys. Scr. Mater. 59(1), 19–22 (2008)

R.P. Jiang, X.Q. Li, M. Zhang, Investigation on the mechanism of grain refinement in aluminum alloy solidified under ultrasonic vibration. Met. Mater. Int. 21(1), 104–108 (2015)

J.-G. Jung et al., Effect of transition elements on the microstructure and tensile properties of Al–12Si alloy cast under ultrasonic melt treatment. J. Alloy. Compd. 712, 277–287 (2017)

S.-B. Kim, Y.-H. Cho, J.-M. Lee, J.-G. Jung, S.-G. Lim, The effect of ultrasonic melt treatment on the microstructure and mechanical properties of Al–7Si–0.35Mg casting alloys. Korean J. Met. Mater. 55(4), 240–246 (2017). (in Korean)

J.-H. Yoon, Y.-H. Cho, J.-G. Jung, J.-M. Lee, I.M. Park, Influence of ultrasonic melt treatment and cooling rates on the microstructural development and elevated temperature mechanical properties of a hypereutectic Al–18Si–4Cu–3Ni piston alloy. Korean J. Metals Mater. 55(6), 396–404 (2017). (in Korean)

C.E. Brennen, Cavitation and Bubble Dynamics (Oxford University Press, Inc., Oxford, 1995)

L.A. Crum, Rectified diffusion. Ultrasonics 22(5), 215–223 (1984)

A. Eller, H.G. Flynn, Rectified diffusion during nonlinear pulsations of cavitation bubbles. J. Acoust. Soc. Am. 37(3), 493–503 (1965)

D.Y. Hsieh, M.S. Plesset, Theory of rectified diffusion of mass into gas bubbles. J. Acoust. Soc. Am. 33(2), 206–215 (1961)

T. Leong, M. Ashokkumar, S. Kentish, The fundamentals of power ultrasound: a review. Acoust. Aust. 39(2), 54–63 (2011)

K. Yasui, Influence of ultrasonic frequency on multibubble sonoluminescence. J. Acoust. Soc. Am. 112(4), 1405–1413 (2002)

X.-F. Shi, L.-Z. Chang, Z.-H. Zhu, J.-J. Wang, L. Zhou, Effect of noncontact ultrasonic technology on solidification quality of electroslag steel. J. Iron Steel Res. Int. 23(11), 1168–1176 (2016)

J. Kang, X. Zhang, Y. Hu, J. Ma, Y. Hu, T. Huang, Ultrasonic treatment of the 304 stainless steel melt. ISIJ Int. 54(2), 281–287 (2014)

O.V. Abramov, Action of high intensity ultrasound on solidifying metal. Ultrasonics 25(2), 73–82 (1987)

L. Qingmei, Z. Yong, S. Yaoling, Q. Feipeng, Z. Qijie, Influence of ultrasonic vibration on mechanical properties and microstructure of 1Cr18Ni9Ti stainless steel. Mater. Des. 28(6), 1949–1952 (2007)

Q. Liu, Q. Zhai, F. Qi, Y. Zhang, Effects of power ultrasonic treatment on microstructure and mechanical properties of T10 steel. Mater. Lett. 61(11–12), 2422–2425 (2007)

K. Nowacki, Influence of ultrasonic treatment on the structure of high-carbon steel. Metalurgija 50(3), 213–216 (2011)

W. Kong, D.-Q. Cang, J.-H. Song, Effects of ultrasonic treatment on dissolved oxygen and nitrogen in liquid low-carbon steel. Philos. Mag. Lett. 92(2), 103–110 (2012)

W. Kong, D.Q. Cang, J.H. Song, Effects of ultrasonic treatment during the solidification process on the structure formation of low carbon steel. Mater. Trans. 52(9), 1844–1847 (2011)

G. Liang, C. Shi, Y.-J. Zhou, D.-H. Mao, Numerical simulation and experimental study of an ultrasonic waveguide for ultrasonic casting of 35CrMo steel. J. Iron. Steel Res. Int. 23(8), 772–777 (2016)

J. Kang, X. Zhang, S. Wang, J. Ma, T. Huang, The comparison of ultrasonic effects in different metal melts. Ultrasonics 57, 11–17 (2015)

G. Liang, C. Shi, Y. Zhou, D. Mao, Effect of ultrasonic treatment on the solidification microstructure of die-cast 35CrMo steel. Metals 6(11), 260 (2016)

Y. Kato, H. Nakato, T. Fujii, S. Ohmiya, S. Takatori, Fluid flow in ladle and its eftect on decarburization rate in RH degasser. ISIJ Int. 33(10), 1088–1094 (1993)

J.-H. Wei, H.-T. Hu, Mathematical modelling of molten steel flow process in a whole RH degasser during the vacuum circulation refining process: application of the model and results. Steel Res. Int. 77(2), 91–96 (2006)

Y.-H. Jang, Y.-T. Kim, K.-W. Yi, Effects of additional bubbling on RH vacuum degassing process with water model experiment. Korean J. Metals Mater. 48(5), 424–429 (2010). (in Korean)

Y.-H. Jang, Analysis of effects on additional bubbling at vacuum vessel in RH vacuum degassing process with water model, M.S. Thesis, Department of Materials Science and Engineering Seoul National University, Seoul (2010)

L. Zhang, F. Li, Investigation on the fluid flow and mixing phenomena in a Ruhrstahl–Heraeus (RH) steel degasser using physical modeling. JOM 66(7), 1227–1240 (2014)

Y.-G. Park, K.-W. Yi, A new numerical model for predicting carbon concentration during RH degassing treatment. ISIJ Int. 43(9), 1403–1409 (2003)

K. Harashima, S. Mizoguchi, M. Matsuo, A. Kiyose, Rates of nitrogen and carbon removal from liquid iron in low content region under reduced pressures. ISIJ Int. 32(1), 111–1119 (1992)

Y.-G. Park, W.-C. Doo, K.-W. Yi, S.-B. An, Numerical calculation of circulation flow rate in the degassing Rheinstahl–Heraeus process. ISIJ Int. 40(8), 749–755 (2000)

Y.-G. Park, K.-W. Yi, S.-B. Ahn, The effect of operating parameters and dimensions of the RH system on melt circulation using numerical calculations. ISIJ Int. 41(5), 403–409 (2001)

Y.-t. Kim, Development of integrated process model of decarburization in RH-OB process, Ph.D., Department of Materials Science and Enginnering, Seoul National University (2010)

M. Yano, S.-Y. Kitamura, K. Harashima, T. Inomoto, K. Azuma, H. Nagahama, Recent advances in ultralow-carbon steel refining technology by vacuum Degassing processes. Nippon Steel Technical Report No. 61 (1994)

S.-Y. Kitamura, M. Yano, K. Harahima, N. Tsutsumi, Decarburization model for vacuum degasser. Tetsu-to-Hagané 80(3), 213–218 (1994). (in Japanese)

J.-H. Wei, H.-T. Hu, Mathematical modelling of non-equilibrium decarburization process during vacuum circulation refining of molten steel: application of the model and results (1)—decarburization process and influences of some technological factors. Steel Res. Int. 79(4), 243–253 (2008)

Acknowledgements

The authors would like to express their gratitude to the Center for Iron and Steel Research at Research Institute of Advanced Materials (RIAM) in Seoul National University for their financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, Yt., Yi, Kw. Effects of the Ultrasound Treatment on Reaction Rates in the RH Processor Water Model System. Met. Mater. Int. 25, 238–247 (2019). https://doi.org/10.1007/s12540-018-0160-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0160-1