Abstract

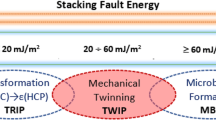

High manganese twinning induced plasticity (TWIP) steel is an attractive material for automotive applications as its use could result in an improved vehicle fuel efficiency and a superior passenger safety. Due to the limited research on the hot deformation behaviour of High Mn steel, the selection of suitable operating conditions for the hot rolling process is challenging. The present contribution focusses on the hot deformation behaviour and the dynamic recrystallization kinetics of V micro-alloyed high manganese TWIP steel, by means of single-hit compression test in the temperature range of 850–1000 °C and the strain rate range of 0.1–10 s−1. The activation energy for hot deformation and the processing map of a V-free TWIP steel and a V-added TWIP steel were compared by analysing their stress–strain curves. The V-added TWIP steel exhibited a higher activation energy than the V-free TWIP steel, i.e. 383.4 kJ/mol versus 372.5 kJ/mol. Processing maps based on a dynamic material model indicated that the hot workability of TWIP steel was decreased by micro-alloying with V. The effect of V on the hot deformation behaviour of TWIP steels was also analysed by means of its effect on the microstructure using the SEM-EBSD technique. The V-added TWIP steel was characterized by a higher peak stress at a lower peak strain as compared to the V-free TWIP steel, indicating that the onset of dynamic recrystallization was accelerated by the addition of V. The rapid dynamic recrystallization kinetics resulted in a smaller recrystallized grain size in the hot deformed microstructure of the V-added TWIP steel.

Similar content being viewed by others

References

O. Grässel, L. Krüger, G. Frommeyer, L.W. Meyer, Int. J. Plast. 16, 1391–1409 (2000)

B.C. De Cooman, K. Chin, J. Kim, New Trends Dev. Automot. Syst. Eng. (2011)

S. Chen, R. Rana, A. Haldar, R.K. Ray, Prog. Mater Sci. 89, 345–391 (2017)

J.K. Kim, M.H. Kwon, B.C. De Cooman, Acta Mater. 141, 444–455 (2017)

B.C. De Cooman, Y. Estrin, S.K. Kim, Acta Mater. 142, 283–362 (2018)

K.M. Rahman, N.G. Jones, D. Dye, Mater. Sci. Eng. A 635, 133–142 (2015)

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, D. Barbier, Curr. Opin. Solid State Mater. Sci. 15, 141–168 (2011)

S. Allain, J.P. Chateau, O. Bouaziz, Mater. Sci. Eng. A 387–389, 143–147 (2004)

E.P. DeGarmo, J.T. Black, R.A. Kohser, Materials and Processes in Manufacturing, 9th edn. (Wiley, Hoboken, 2003)

C.M. Sellars, Mater. Sci. Technol. 6, 1072–1081 (1990)

P.H. Adler, G.B. Olson, W.S. Owen, Metall. Mater. Trans. A 17, 1725–1737 (1986)

I.A. Yakubtsov, A. Ariapour, D.D. Perovic, Acta Mater. 47, 1271–1279 (1999)

S. Allain, J.P. Chateau, D. Dahmoun, O. Bouaziz, Mater. Sci. Eng. A 387–389, 272–276 (2004)

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, N. Guelton, Mater. Sci. Eng. A 387–389, 158–162 (2004)

L. Krüger, L.W. Meyer, U. Brûx, G. Frommeyer, O. Grässel, J. Phys. IV Fr. 110, 189–194 (2003)

A.S. Hamada, L.P. Karjalainen, Mater. Sci. Eng. A 528, 1819–1827 (2011)

A.S. Hamada, M.C. Somani, L.P. Karjalainen, ISIJ Int. 47, 907–912 (2007)

F. Reyes-Calderón, I. Mejía, A. Boulaajaj, J.M. Cabrera, Mater. Sci. Eng. A 560, 552–560 (2013)

W. Xiong, B. Wietbrock, A. Saeed-Akbari, M. Bambach, G. Hirt, Steel Res. Int. 82, 127–136 (2011)

Y.V.R.K. Prasad, T. Seshacharyulu, Int. Mater. Rev. 43, 243–258 (1998)

K. Minami, F. Siciliano Jr., T.M. Maccagno, J.J. Jonas, ISIJ Int. 36, 1507–1515 (1996)

F.J. Humphreys, M. Hatherl, Recrystallization and Related Annealing Phenomena (Pergamon, Oxford, 1995)

A. Dehghan-Manshadi, M.R. Barnett, P.D. Hodgson, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 39, 1359–1370 (2008)

A. Cingara, H.J. McQueen, J. Mater. Process. Technol. 36, 31–42 (1992)

C. Zener, J.H. Hollomon, J. Appl. Phys. 15, 22–32 (1944)

H. Mirzadeh, J.M. Cabrera, J.M. Prado, A. Najafizadeh, Mater. Sci. Eng. A 528, 3876–3882 (2011)

X. Huang, H. Zhang, Y. Han, W. Wu, J. Chen, Mater. Sci. Eng. A 527, 485–490 (2010)

N. Jin, H. Zhang, Y. Han, W. Wu, J. Chen, Mater. Charact. 60, 530–536 (2009)

A. Dehghan-Manshadi, M.R. Barnett, P.D. Hodgson, Mater. Sci. Eng. A 485, 664–672 (2008)

X.Y. Liu, Q.L. Pan, Y. Bin He, W. Bin Li, W.J. Liang, Z.M. Yin, Mater. Sci. Eng. A 500, 150–154 (2009)

S. Banerjee, P.S. Robi, A. Srinivasan, L. Praveen Kumar, Mater. Sci. Eng. A 527, 2498–2503 (2010)

G. Ji, F. Li, Q. Li, H. Li, Z. Li, Mater. Sci. Eng. A 527, 2350–2355 (2010)

F. Reyes-Calderón, I. Mejía, J.M. Cabrera, Mater. Sci. Eng. A 562, 46–52 (2013)

M.C. Somani, D.A. Porter, A.S. Hamada, L.P. Karjalainen, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 46, 5329–5342 (2015)

N. Cabañas, N. Akdut, J. Penning, B.C. De Cooman, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 37, 3305–3315 (2006)

L. Llanos, B. Pereda, B. Lopez, J.M. Rodriguez-Ibabe, Mater. Sci. Eng. A 651, 358–369 (2016)

J. Zhang, H. Di, X. Wang, Y. Cao, J. Zhang, T. Ma, Mater. Des. 44, 354–364 (2013)

O.A. Zambrano, J. Valdés, Y. Aguilar, J.J. Coronado, S.A. Rodríguez, R.E. Logé, Mater. Sci. Eng. A 689, 269–285 (2017)

R. Raj, Metall. Trans. A 12, 1089–1097 (1981)

H. Ziegler, Progress in Solid Mechanics (North-Holland Publishing Company, Amsterdam, 1963)

M. Jang, J. Kang, J. Hoon, T. Lee, C. Lee, Mater. Charact. 123, 207–217 (2017)

B.C. De Cooman, J.G. Speer, Fundamentals of Steel Product Physical Metallurgy (Assn of Iron & Steel Engineers, Warrendale, 2011)

B.V. Petukhov, Crystallogr. Reports 52, 112–122 (2007)

Acknowledgements

The authors gratefully acknowledge the support of the POSCO Technical Research Laboratories in Gwangyang, Republic of Korea. The authors also acknowledge the support of the Ministry of Strategy and Finance (Code No. JA180018).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gwon, H., Shin, S., Jeon, J. et al. Hot Deformation Behavior of V Micro-Alloyed TWIP Steel During Hot Compression. Met. Mater. Int. 25, 594–605 (2019). https://doi.org/10.1007/s12540-018-00224-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-00224-9