Abstract

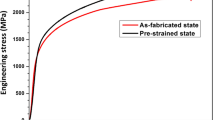

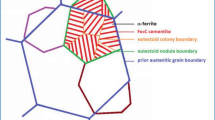

The correlations of the microstructural factors with the tensile and crack tip opening displacement (CTOD) properties at −20 and −60 °C for three kinds of API linepipe steels were investigated. The C steel composed mainly of small-sized acicular ferrite exhibited excellent tensile and CTOD properties. On the other hand, the A and B steels with large-sized polygonal ferrite or granular bainite exhibited low CTOD properties at −60 °C. The effective grain size was inversely proportional to the CTOD value at low temperatures. In the A and B steels, the values of the plastic deformation area and the CTOD were low because the crack tips of the steels opened under a low maximum force due to the fracture mode of the unstable brittle crack extension behavior. In the C steel, however, the values of the plastic deformation area and the CTOD were high because the crack tip of the steel opened under a high maximum force due to the fracture mode of almost fully plastic behavior. The C steel showed the widest stretch zone and the highest CTOD value. The CTOD values and the portions of post elongation in the A and B steels decreased with decreasing test temperature.

Similar content being viewed by others

References

R. Deny, Pipeline Technology, p.1, Elsevier, Netherlands (2000).

D. P. Fairchild, M. L. Macia, S. D. Papka, C. W. Petersen, J. H. Stevens, S. T. Barbas, N. V. Bangaru, J. Y. Koo, and M. J. Luton, Proc. Int. Pipe Dreamer’s Conf., p.307, Scientific Surveys, Ltd., Yokohama, Japan (2002).

K. T. Corbett, R. R. Bowen, and C. W. Petersen, Int. J. Offshore. Polar. 14, 75 (2004).

J. Y. Koo, M. J. Luton, N. V. Bangaru, R. A. Petkovic, D. P. Fairchild, C. W. Petersen, H. Asahi, T. Hara, Y. Terada, M. Sugiyama, H. Tamehiro, Y. Komizo, S. Okaguchi, M. Hamada, A. Yamamoto, and I. Takeuchi, Proc. 13th Int. Offshore and Polar Engineering Conf., p.10, Honolulu, USA (2003).

D. B. Lillig, Proc. 18th Int. Offshore and Polar Engineering Conf., p.1, Vancouver, Canada (2008).

H. K. Sung, S. Y. Shin, B. Hwang, C. G. Lee, and S. Lee, Metall. Mater. Trans. A 43A, 3703 (2012).

API, API Recommended Practice 5L3, API, Washington DC, USA (1996).

G. Mannucci and D. Harris, Fracture Properties of API X100 Gas Pipeline Steels, p.1, Final Report, European Commission (2002).

D. J. Horsley, Eng. Fract. Mech. 70, 547 (2003).

S. Y. Shin, G. Gong, S. Kim, and S. Lee, Metall. Mater. Trans. A 38A, 1012 (2007).

ASTM Standard E8m-09, Standard Test Method for Tensile Testing of Metallic Materials, ASTM, West Conshohocken, PA, USA (2009).

ASTM Standard E1290, Standard Test Method for Crack-Tip Opening Displacement (CTOD) Fracture Toughness Measurement, ASTM, West Conshohocken, PA, USA (2008).

ASTM Standard E23, Standard Test Method for Notched Bar Impact Testing of Metallic Materials, ASTM, West Conshohocken, PA, USA (2007).

J.-I. Jang, Y. Choi, J.-S. Lee, Y.-H. Lee, D. Kwon, M. Dao, and R. Kania, Int. J. Fracture. 131, 15 (2005).

S. Y. Shin, B. Hwang, S. Lee, N. J. Kim, and S. S. Ahn, Mater. Sci. Eng. A A 458, 281 (2007).

Y. M. Kim, S. K. Kim, Y. J. Lim, and N. J. Kim, ISIJ Int., 42, 1571 (2002).

C.-H. Seo, K. H. Kwon, K. Choi, K.-H. Kim, J. H. Kwak, S. Lee, and N. J. Kim, Scripta Mater. 66, 519 (2012).

J.-S. Kim, J. B. Jeon, J. E. Jung, K.-K Um, and Y. W. Chang, Met. Mater. Int. 20, 41 (2014).

T. Araki, Atlas for Bainitic Microstructures, vol.1, p.4, ISIJ, Tokyo, Japan (1992).

G. Krauss and S. W. Thompson, ISIJ Int. 35, 937 (1995).

S. W. Thompson, D. J. Colvin, and G. Krauss, Metall. Trans. A 21A, 1493 (1990).

H. K. D. H. Bhadeshia, Mater. Sci. Eng. A A 378, 34 (2004).

A. Weidner, T. Mottitschka, H. Biermann, and S. Henkel, Eng. Fract. Mech. 108, 294 (2013).

B. L. Bramfitt and J. G. Speer, Metall. Trans. A 21A, 817 (1990).

G. E. Dieter, Mechanical Metallurgy, 3rd ed., p.292, McGraw-Hill Book Co., New York (1988).

E. V. Morales, R. A. Silva, I. S. Bott, and S. Paciornik, Mater. Sci. Eng. A-Struct. A 585, 253 (2013).

J. Ju, W. Kim, and J. Jang, Mater. Sci. Eng. A-Struct. A 546, 258 (2012).

Y. T. Shin and H. W. Lee, Met. Mater. Int. 18, 863 (2012).

S. Y. Han, S. Y. Shin, S. Lee, N. J. Kim, J.-H. Bae, and K. Kim, Metall. Mater. Trans. A 41A, 329 (2010).

L. J. Habraken and M. Economopoulos, Transformation and Hardenability in Steels, p.15, Climax Molybdenum Co., Ann Arbor, MI (1967).

W. E. Wolff, Proc. 73rd Annual Meeting of the American Society for Testing and Materials, p.3, ASTM Spec. Tech. Publ. (1971).

W. A. Spitzig, Trans ASM 61, 344 (1968).

J. D. Landes and J. A. Begley, Proc. 8th Conf. on Fracture Analysis, p.170, ASTM Spec. Tech. Publ. (1974).

S. K. Putatunda and J. M. Rigsbee, Mater. Sci. Eng. A-Struct. A70, 111 (1985).

W. O. Soboyejo, J. Zhou, J. Crompton, T. McGaughy, and F. Orth, Metall. Mater. Trans. A 32A, 533 (2001).

A. Ghosh, S. Kundub, and D. Chakrabarti, Scripta Mater. 81, 8 (2014).

S. Y. Shin, Metall. Mater. Trans. A 44A, 2613 (2013).

D. Liu, Q. Li, and T. Emi, Metall. Mater. Trans. A 42A, 1349 (2011).

C. Garcia-Mateo, F.G. Caballero, T. Sourmail, J. Cornide, V. Smanio, and R. Elvira, Met. Mater. Int. 20, 405 (2014).

J. Lee, M. Lee, H. Do, S. Kim, and N. Kang, Korean J. Met. Mater. 52, 113 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, M., Kim, H., Lee, S. et al. Correlation of microstructure with tensile and crack tip opening displacement properties at low temperatures in API linepipe steels. Met. Mater. Int. 21, 628–638 (2015). https://doi.org/10.1007/s12540-015-4607-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-015-4607-3