Abstract

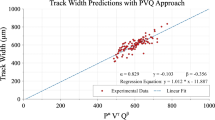

The Direct energy deposition (DED) process has been a popular method for improving surface properties in mold industries. The deposited bead geometry and dilution depth, representing the thickness of the melted substrate mixed with deposited materials, play an important role in determining the mechanical properties of the deposited part. Therefore, selecting and controlling the DED process parameters is very important for obtaining the optimal deposited bead geometry. This study, investigated the effects of process parameters on deposited single-track geometry using AISI M4 powder. The cross-sectional profile of the deposited bead was analyzed to understand the effects of each processing condition on bead geometry. Moreover, a mathematical formula for bead geometry prediction was derived using the Response surface method (RSM), which can be used to effectively control the process variables to achieve the desired qualities.

Similar content being viewed by others

References

I. Gibson, D. Rosen and B. Stucker, Additive manufacturing technologies, Springer, New York (2015).

Q. Ming, L. C. Lima and Z. D. Chen, Laser cladding of nickel-based hardfacing alloys, Surface and Coatings Technology, 106 (2–3) (1998) 174–182.

G. P. Dinda, A. K. Dasgupta and J. Mazumder, Laser aided direct metal deposition of Inconel 625 superalloy: microstructural evolution and thermal stability, Materials Science and Engineering: A, 509 (1–2) (2009) 98–104.

J. Mazumder, D. Dutta, N. Kikuchi and A. Ghosh, Closed loop direct metal deposition: art to part, Optics and Lasers in Engineering, 344 (4–6) (2000) 397–414.

Y. Sun and M. Hao, Statistical analysis and optimization of process parameters in Ti6Al4V laser cladding using Nd:YAG laser, Optics and Lasers in Engineering, 50 (7) (2012) 985–995.

J. Choi and Y. Chang, Characteristics of laser aided direct metal/material deposition process for tool steel, International Journal of Machine Tools and Manufacture, 45 (4–5) (2005) 597–607.

Y. P. Kathuria, Laser-cladding process: a study using stationary and scanning CO2 laser beams, Surface and Coatings Technology, 97 (1–3) (1997) 442–447.

M. Qian, L. C. Lim, Z. D. Chen and W. L. Chen, Parametric studies of laser cladding processes, Journal of Materials Processing Technology, 63 (1–3) (1997) 590–593.

J. D. Kim and Y. Peng, Melt pool shape and dilution of laser cladding with wire, Journal of Materials Processing Technology, 104 (3) (2000) 284–293.

J. Paulo Davim, C. Oliveira and A. Cardoso, Laser cladding: experimental study of geometric form and hardness of coating using statistical analysis, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering, 220 (9) (2006) 1549–1554.

G. Singh, R. S. Pai and V. K. Devi, Response surface methodology and process optimization of sustained release pellets using Taguchi orthogonal array design and central composite design, Journal of Advanced Pharmaceutical Technology & Research, 3 (1) (2012) 30–40.

T. Belwal, P. Dhyani, I. D. Bhatt, R. S. Rawal and V. Pande, Optimization extraction conditions for improving phenolic content and antioxidant activity in Berberis asiatica fruits using response surface methodology (RSM), Food Chemistry, 207 (2016) 115–124.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Young Whan Park

Do-Sik Shim received Ph.D. in Mechanical Engineering from KAIST, Korea in 2010. He has been an Assistant Professor at Korea Maritime and Ocean University (KMOU) since 2017. His research interests include incremental and roll forming for sheet metal, direct energy deposition (DED) and structural analysis as well as optimal design.

Rights and permissions

About this article

Cite this article

Lee, E.M., Shin, G.Y., Yoon, H.S. et al. Study of the effects of process parameters on deposited single track of M4 powder based direct energy deposition. J Mech Sci Technol 31, 3411–3418 (2017). https://doi.org/10.1007/s12206-017-0239-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0239-5