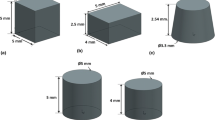

Aluminum and copper cylindrical shells were plastically buckled under quasi-static and dynamic loading conditions with an Absorption Compression-Torsion Plasticity (ACTP: Patent No. WO 2005090822) combined mechanical testing device. Optical microscopy and transmission electron microscopy (TEM) analysis were used to study the microscopic evolutions in the mechanically buckled aluminum and copper alloy samples. Optical microscopy showed evidence of the presence of second-phase particles in both the aluminum and copper alloys samples. Under dynamic loading aluminum samples showed more energy absorption as compared to copper samples. Material flow lines were more pronounced in the copper samples when observed by optical microscopy. The evidence that supports the increased energy absorption in the aluminum cylindrical shells can be supported by the TEM analysis more than the optical microscopy analysis. The TEM results showed highly oriented textured morphology with the presence of few dislocation cells structures and sub-structures.

Similar content being viewed by others

References

Callandine, C.R., English, R.W., 1984, Strain-Rate and Inertia Effects in the Collapse of Two Energy Absorbing Structures, Int. J. Mech. Sci., 26, p 689–701

Reid, S.R., 1993, Plastic Deformation Mechanisms in Axially Compressed Metal Tubes Used as Impact Energy Absorbers, Int. J. Mech. Sci., 35, p 1035–1052

A.A.A. Al-Ghamdi, Collapsible Impact Energy Absorbers: An Overview, Thin Walled Struct., 2000, 39, p 189–213

Jones, N., 1998, Some Recent Developments and Future Trends in Thin-Walled Sections for Structural Crashworthiness, Thin Wall Struct., 32, p 231–233

Karagiozova, D., Jones, N., 2000, Dynamic Elastic-Plastic Buckling of Circular Cylindrical Shells Under Axial Impact, Int. J. Solids Struct., 37, p 2005–2034

Karagiozova, D., Jones, N., 2002, On Dynamic Buckling Phenomena in Axially Loaded Elastic-Plastic Cylindrical Shells, Int. J. NonLinear Mech., 37, p 1223–1238

Karagiozova, D., Jones, N., 2001, Dynamic Effects on Buckling and Energy Absorption of Cylindrical Shells Under Axial Impact, Thin Walled Struct., 39, p 583–610

Baleh, R., Abdul-Latif, A., 2007, Quasi-Static Biaxial Plastic Buckling of Tubular Structures Used as an Energy Absorber, J. Appl. Mech., 74, p 628–635

A. Abdul-Latif and R. Baleh, Dynamic Biaxial Plastic Buckling of Circular Shells, J. Appl. Mech., 2007 (in press)

Abdul-Latif, A., Baleh, R., Aboura, Z. 2006, Some Improvements on the Energy Absorbed in Axial Plastic Collapse of Hollow Cylinders, Int. J. Solids Struct., 43, p 1543–1560

Johnson, W., Reid, S.R., 1986, Metallic Energy Dissipating Systems, Appl. Mech. Rev., 31, p 277–288

Acknowledgments

The authors wish to thank Mr. C. Kinney for his help with the metallographic preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Drusina, N., Mahapatra, R., Abdul-Latif, A. et al. Microstructure Analysis of Aluminum Alloy and Copper Alloy Circular Shells After Multiaxial Plastic Buckling. J. of Materi Eng and Perform 17, 755–766 (2008). https://doi.org/10.1007/s11665-008-9216-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9216-6