Abstract

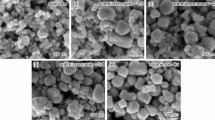

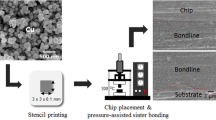

A one-step polyol method was employed to synthesize bimodal Cu particles with average diameters around 200 nm and 1000 nm, respectively. The bimodal Cu particles were mixed with a reductive solvent of polyethylene glycol (PEG) to form a paste. The Cu paste was used as die bonding material to prepare Cu joints under N2 or vacuum sintering atmosphere. The results showed that the strength of the Cu joints in N2 atmosphere was always higher than that in vacuum. The shear strength of a Cu joint processed at 350°C under only 0.4 MPa bonding pressure in N2 was above 40 MPa, which was far higher than that obtained using single-sized nano-Cu particle paste. It is related to the dense packing of the bimodal Cu particles and slow decomposition behavior of the reductive PEG solvent. The reductive PEG solvent in the Cu paste, which effectively removed oxides on the surface of the Cu particles, was necessary for easy-oxidized Cu pastes. These results suggested that Cu pastes with suitable particle sizes, reducing solvent and sintering atmosphere could be a proper candidate for low-temperature and low-pressure bonding process.

Similar content being viewed by others

References

F. Roccaforte, P. Fiorenza, G. Greco, M. Vivona, R.L. Nigro, F. Giannazzo, A. Patti, and M. Saggio, Appl. Surf. Sci. 301, 9 (2014).

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.S. Kim, and M. Nogi, Microelectron. Reliab. 52, 375 (2012).

H.S. Chin, K.Y. Cheong, and A.B. Ismail, Metall. Mater. Trans. B 41, 824 (2010).

V.R. Manikam, K.Y. Cheong, and I.E.E.E. Trans, Compon. Packag. Manuf. Technol. 1, 457 (2011).

T. Wang, X. Chen, G.Q. Lu, and G.Y. Lei, J. Electron. Mater. 36, 1333 (2007).

S. Sakamoto, S. Nagao, and K. Suganuma, J. Mater. Sci. Mater. Electron. 24, 2593 (2013).

Y. Morisada, T. Nagaoka, M. Fukusumi, Y. Kashiwagi, M. Yamamoto, M. Nakamoto, H. Kakiuchi, and Y. Yoshida, J. Electron. Mater. 40, 2398 (2011).

R. Khazaka, L. Mendizabal, and D. Henry, J. Electron. Mater. 43, 2459 (2014).

A.R. Rathmell, S.M. Bergin, Y.L. Hua, Z.Y. Li, and B.J. Wiley, Adv. Mater. 22, 3558 (2010).

S. Bhanushali, P. Ghosh, A. Ganesh, and W. Cheng, Small 11, 1232 (2015).

X. Liu and H. Nishikawa, Scrip. Mater. 120, 80 (2016).

H. Nishikawa, T. Hirano, T. Takemoto, and N. Terada, Open Surf. Sci. J. 3, 60 (2011).

T. Ishizaki and R. Watanabe, J. Mater. Chem. 22, 25198 (2012).

S. Jeong, S.H. Lee, Y. Jo, S.S. Lee, Y.H. Seo, B.W. Ahn, G. Kim, G.E. Jang, J.U. Park, and B.H. Ryu, J. Mater. Chem. C 1, 2704 (2014).

S.W. Park, R. Uwataki, S. Nagao, T. Sugahara, Y. Katoh, H. Ishino, K. Sugiura, K. Tsuruta, and K. Suganuma, in Electronic Components and Technology Conference (ECTC), 2014 IEEE 64th, (2014), pp. 1179–1182.

S. Soichi, K. Suganuma, and I.E.E.E. Trans, Compon. Packag. Manuf. Technol. 3, 923 (2013).

J. Jiu, K. Murai, K. Kim, and K. Suganuma, J. Mater. Sci. Mater. Electron. 21, 713 (2010).

J. McCoppin, T.L. Reitz, R. Miller, H. Vijwani, S. Mukhopadhyay, and D. Young, J. Electron. Mater. 43, 3379 (2014).

S.J. Joo, H.J. Hwang, and H.S. Kim, Nanotechnology 25, 265601 (2014).

S.K. Tam, K.Y. Fung, and K.M. Ng, J. Mater. Sci. 51, 1914 (2016).

J. Jiu, H. Zhang, S. Nagao, T. Sugahara, N. Kagami, Y. Suzuki, Y. Akai, and K. Suganuma, J. Mater. Sci. 51, 3422 (2016).

Y. Li, K. Moon, H. Li, and C.P. Wong, in Electronic Components and Technology Conference, 2004. Proceedings. 54th, (2004), pp. 1959–1964.

C.A. Lu, P. Lin, H.C. Lin, and S.F. Wang, Jpn. J. Appl. Phys. 46, 251 (2007).

I. Kim and S. Chun, J. Electron. Mater. 40, 1977 (2011).

T. Ogura, S. Takata, M. Takahashi, and A. Hirose, Mater. Trans. 56, 1030 (2015).

T. Ogura, T. Yagishita, S. Takata, T. Fujimoto, and A. Hirose, Mater. Trans. 54, 860 (2013).

Y. Gao, H. Zhang, J. Jiu, S. Nagao, T. Sugahara, and K. Suganuma, RSC Adv. 5, 90202 (2016).

J.L.C. Huaman, K. Sato, S. Kurita, T. Matsumoto, and B. Jeyadevan, J. Mater. Chem. 21, 7062 (2011).

B.K. Park, S. Jeong, D. Kim, J. Moon, S. Lim, J.S. Kim, and J. Colloid, Interface Sci. 311, 417 (2007).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gao, Y., Zhang, H., Li, W. et al. Die Bonding Performance Using Bimodal Cu Particle Paste Under Different Sintering Atmospheres. J. Electron. Mater. 46, 4575–4581 (2017). https://doi.org/10.1007/s11664-017-5464-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5464-2