Abstract

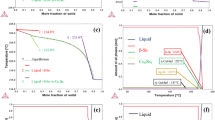

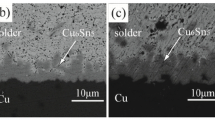

The growth behavior of intermetallic compounds (IMC) in Cu/Sn3.0Ag0.5Cu solder joints, including the interfacial Cu6Sn5 layer and Ag3Sn, and Cu6Sn5 in the solder, were investigated when different cooling methods—quenched water, cooling in air, and cooling in a furnace after reflow—were used. For the solder joint quenched in water, no obvious Cu6Sn5 or Ag3Sn was detected in the solder, and the thickness of interfacial Cu6Sn5 layer was slightly thinner than that of the joint cooled in air. On the basis of results from scanning electron microscopy and energy-dispersive spectrometry, a mechanism is proposed for growth of IMC in Sn3.0Ag0.5Cu solder during solidification. The rate of cooling has a substantial effect on the morphology and size of Ag3Sn, which evolved into large plate-like shapes when the joint was cooled slowly in a furnace. However, the morphology of Ag3Sn was branch-like or particle-like when the joint was cooled in air. This is attributed to re-growth of Ag3Sn grains via substantial atomic diffusion during the high-temperature stage of furnace cooling.

Similar content being viewed by others

References

K. Kanlayasiri, M. Mongkolwongrojn, and T. Ariga, J. Alloys Compd. 485, 225 (2009).

T. Fouzder, I. Shafiq, Y.C. Chan, A. Sharif, and W.K.C. Yung, J. Alloys Compd. 509, 1885 (2011).

C.Y. Lin, U.S. Mohanty, and J.H. Chou, J. Alloys Compd. 501, 204 (2010).

A.K. Gain, Y.C. Chan, A. Sharif, and W.K.C. Yung, Microelectron. Eng. 86, 2347 (2009).

R. Mayappan and Z. Ahmad, Intermetallics 18, 730 (2010).

Y. Li, K. Moon, and C.P. Wong, Science 308, 1419 (2005).

L. Yang and Z. Zhang, J. Electron. Mater. 42, 3552 (2013).

A.K. Gain and Y.C. Chan, Intermetallics 29, 48 (2012).

L.C. Tsao, J. Alloys Compd. 509, 8441 (2011).

L. Snugovsky, P. Snugovsky, D.D. Perovic, T. Sack, and J.W. Rutter, Mater. Sci. Technol. 21, 53 (2005).

G. Cuddalorepatta, Acta Mater. 58, 5989 (2010).

J. Keller, Acta Mater. 59, 2731 (2011).

F. Guo, S. Choi, K.N. Subramanian, T.R. Bieler, J.P. Lucas, A. Achari, and M. Paruchuri, Mater. Sci. Eng. A 351, 190 (2003).

K. Zeng, Mater. Sci. Eng. R 38, 55 (2002).

H. Chen, J. Han, J. Li, and M. Li, Microelectron. Reliab. 52, 112 (2012).

L. Snugovsky, D.D. Perovic, and J.W. Rutter, Mater. Sci. Technol. 20, 1403 (2004).

K.S. Kim, S.H. Huh, and K. Suganuma, Mater. Sci. Eng. A 333, 106 (2002).

H.F. Zou, H.J. Yang, and Z.F. Zhang, Acta Mater. 56, 2649 (2008).

H.K. Kim and K.N. Tu, Phys. Rev. B 53, 16027 (1996).

Q.K. Zhang and Z.F. Zhang, Acta Mater. 59, 6017 (2011).

X. Liua, M. Huang, Y. Zhao, C.M.L. Wu, and L. Wang, J. Alloys Compd. 492, 433 (2010).

H.T. Ma, L. Qu, M.L. Huang, L.Y. Gu, N. Zhao, and L. Wang, J. Alloys Compd. 537, 286 (2012).

L.M. Yang, S.Y. Quan, Y.D. Yang, and G.M. Shi, J. Nanosci. Nanotechnol. 12, 2700 (2012).

A.S.M.A. Haseeb, M.M. Arafat, and M.R. Johan, Mater. Charact. 64, 27 (2012).

L. Qi, J. Huang, X. Zhao, and H. Zhang, J. Alloys Compd. 469, 102 (2009).

J.H. Yao, K.R. Elder, H. Guo, and M. Grant, Phys. Rev. B 47, 14110 (1993).

Y. Takamatsu, H. Esaka, and K. Shinozuka, Mater. Trans. 52, 189 (2011).

D.Q. Yu, L. Wang, C.M.L. Wu, and C.M.T. Law, J. Alloys Compd. 389, 153 (2005).

H.T. Lee and Y.F. Chen, J. Alloys Compd. 509, 2510 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Zhang, Z.F. Growth Behavior of Intermetallic Compounds in Cu/Sn3.0Ag0.5Cu Solder Joints with Different Rates of Cooling. J. Electron. Mater. 44, 590–596 (2015). https://doi.org/10.1007/s11664-014-3530-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3530-6