Abstract

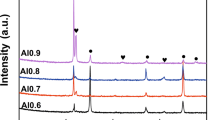

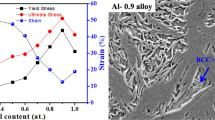

The Al x CoCrCuFeNi alloys with multiprincipal elements (x=the aluminum content in molar ratio, from 0 to 3.0) were synthesized using a well-developed arc-melting and casting method, and their mechanical properties were investigated. These alloys exhibited promising mechanical properties, including excellent elevated-temperature strength and good wear resistance. With the addition of aluminum from x=0 to 3.0, the hardness of the alloys increased from HV 133 to 655, mainly attributed to the increased portion of strong bcc phase to ductile fcc phase, both of which were strengthened by the solid solution of aluminum atoms and the precipitation of nanophases. The alloys exhibited superior high-temperature strengths up to 800 °C, among which the Al0.5CoCrCuFeNi alloy, especially, had enhanced plasticity and a large strain-hardening capacity. Moreover, the wear resistance of these alloys was similar to that of ferrous alloys at the same hardness level, while the alloys with lower hardness exhibited relatively higher resistance because of their large strain-hardening capacity.

Similar content being viewed by others

References

Handbook Committee: Metals Handbook, 10th ed., ASM INTERNATIONAL, Metals Park, OH, 1990, vol. 1, pp. 3–949.

Handbook Committee: Metals Handbook, 10th ed., ASM INTERNATIONAL, Metals Park, OH, 1990, vol. 2, pp. 3–757.

C.T. Sims: in The Superalloys, C.T. Sims and W.C. Hagel, eds., John Wiley & Sons, New York, NY, 1972, pp. 3–284.

Handbook Committee: Metals Handbook, 10th ed., ASM INTERNATIONAL, Metals Park, OH, 1990, vol. 2, pp. 913–42.

A. Takeuchi and A. Inoue: Mater. Trans. JIM, 2000, vol. 41, pp. 1372–78.

A. Inoue: Bulk Amorphous Alloys—Preparation and Fundamental Characteristics, Materials Science Foundations, Trans Tech Publications, Aedermannsdorf, Netherlands, 1998, vol. 4, pp. 1–116.

H.W. Kui, A.L. Greer, and D. Turnbull: Appl. Phys. Lett., 1984, vol. 45, pp. 615–16.

A. Inoue, K. Ohtera, K. Kita, and T. Masumoto: Jpn. J. Appl. Phys., 1988, vol. 27, pp. L2248-L2251.

A. Inoue, T. Zhang, and T. Masumoto: Mater. Trans. JIM, 1989, vol. 30, pp. 965–72.

A. Inoue, T. Zhang, and T. Masumoto: Mater. Trans. JIM, 1990, vol. 31, pp. 177–83.

A. Peker and W.L. Johnson: Appl. Phys. Lett., 1993, vol. 63, pp. 2342–44.

R. Akatsuka, T. Zhang, M. Koshiba, and A. Inoue: Mater. Trans. JIM, 1999, vol. 40, pp. 58–261.

T. Zhang and A. Inoue: Mater. Trans. JIM, 1998, vol. 39, pp. 857–62.

B. Cantor, K.B. Kim, and P.J. Warren: Mater. Sci. Forum, 2002, vol. 386, pp. 27–31.

K.B. Kim, P.J. Warren, and B. Cantor: Mater. Trans., 2003, vol. 44, pp. 411–13.

K.B. Kim, P.J. Warren, and B. Cantor: J. Non-Crystal. Solids, 2003, vol. 317, pp. 17–22.

K.B. Kim, Y. Zhang, P.J. Warren, and B. Cantor: Phil. Mag., 2003, vol. 83, pp. 2371–81.

S. Ranganathan: Curr. Sci., 2003, vol. 85, pp. 1404–06.

P.K. Huang, J.W. Yeh, T.T. Shun, and S.K. Chen: Adv. Eng. Mater., 2004, vol. 6, pp. 74–78.

C.Y. Hsu, J.W. Yeh, S.K. Chen, and T.T. Shun: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1465–69.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Adv. Eng. Mater., 2004, vol. 6, pp. 299–303.

J.W. Yeh, S.K. Chen, J.Y. Gan, S.J. Lin, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2533–36.

C.J. Tong, Y.L. Chen, S.K. Chen, J.W. Yeh, T.T. Shun, C.H. Tsau, S.J. Lin, and S.Y. Chang: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 881–93.

A. Lindsay Greer: Nature, 1993, vol. 366, pp. 303–04.

R.A. Swalin: in Thermodynamics of Solids, 2nd ed., E. Burke, B. Chalmers, and J.A. Krumhansl, eds., John Wiley & Sons, New York, NY, 1991, pp. 21–87.

W.D. Callister, Jr.: Materials Science and Engineering, 6th ed., John Wiley & Sons, New York, NY, 2003, pp. i-ii and pp. 18–19.

H. Bakker: Enthalpies in Alloys, Materials Science Foundations, Trans Tech Publications, Netherlands, 1998, vol. 1, pp. 1–78.

C. Kittel: Introduction to Solid-State Physics, 7th ed., John Wiley & Sons, New York, NY, 1996, p. 23.

M.M. Khruschov: Wear, 1974, vol. 28, pp. 69–88.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tong, CJ., Chen, MR., Yeh, JW. et al. Mechanical performance of the Al x CoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mater Trans A 36, 1263–1271 (2005). https://doi.org/10.1007/s11661-005-0218-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0218-9