Abstract

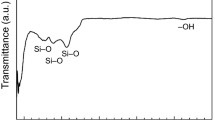

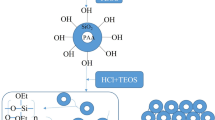

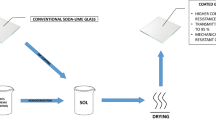

SiO2-polymer hybrid thick and hard coating films were successfully obtained via sol–gel process with a heat treatment at 200 °C. The films were achieved by control of hydrolysis and poly-condensation reaction of silica species. Key parameters were pH, water content and additional polymer in the coating solution. No-cracking and highly transparent films were formed with polymer content in a range from 28 to 42 mass% [vs. SiO2]. Their thickness was varied from 2.6 to 3.5 μm with an increase in the polymer content. The haze values of the films after Taber abrasion were very low in a range from 1.3 to 2.7%, and the pencil hardness was over 9H. Moreover, no-damage was observed on the surface after steel wool abrasion with 4 kg loaded. These high mechanical strengths were come up to that of float glass, so that the coating films prepared by this process have a great potential for application to architectural and automotive window glass.

Similar content being viewed by others

References

Muromachi T, Tsujino T, Kamitani K, Maeda K (2006) Application of functional coatings by sol-gel method. J Sol-Gel Sci Tech 40(2):267–272

Sanchez C, Julian B, Belleville P, Popall M (2005) Applications of hybrid organic–inorganic nanocomposites. J Mater Chem 15:3559–3592

Ogoshi T, Chujo Y (2005) Organic–inorganic polymer hybrids prepared by the sol-gel method. J Sol-Gel Sci Tech 11(8):539–566

Wen J, Vasudevan VJ, Wilkes GL (1995) Abrasion resistant inorganic–organic coating materials prepared by the sol-gel method. J Sol-Gel Sci Tech 5:115–126

Atanacio AJ, Latella BA, Barbe CJ, Swain MV (2005) Mechanical properties and adhesion characteristics of hybrid sol-gel thin films. Surf Coat Tech 192:354–364

Mammeri F, Le Bourhis E, Rozes L, Sanchez C (2005) Mechanical properties of hybrid organic–inorganic materials. J Mater Chem 15(35–36):3787–3811

Wang Z, Lu J, Li Y, Fu SY, Jiang S, Zhao X (2006) Studies on thermal and mechanical properties of PI/SiO2 nanocomposite films at low temperature. Compos Part A 37:74–79

Chan CK, Chu IM, Ou CF, Lin YW (2004) Interfacial interactions and their influence to phase behavior in poly(vinyl pyrrolidone)/silica hybrid materials prepared by sol-gel process. Mater Lett 58:2243–2247

Tanaka N, Kobayashi H, Nakanishi K, Minakuchi H (2001) Monolithic LC colums. Anal Chem 73(15):420A–429A

Soler-Illia GJDA, Sanchez C (2000) Interactions between poly(ethylene oxide)-based surfactants and transition metal alkoxides: their role in the templated construction of mesostructured hybrid organic–inorganic composites. New J Chem 24(7):493–499

Dahmouche K, Santilli CV, Pulcinelli SH (1999) Small-angle X-ray scattering study of sol-gel-derived siloxane-PEG and siloxane-PPG hybrid materials. J Phys Chem B 103:4937–4942

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sasaki, T., Kamitani, K. Preparation of thick and hard coating films via sol–gel process with a low temperature treatment. J Sol-Gel Sci Technol 46, 180–189 (2008). https://doi.org/10.1007/s10971-008-1685-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-008-1685-4