Abstract

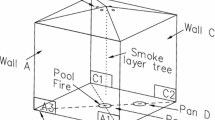

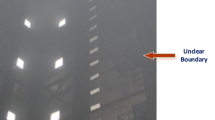

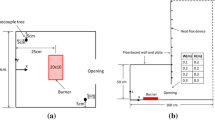

This study examines the possible effects of various make-up air supply arrangements and velocities in an atrium smoke management system. Variations include velocities ranging from 0.5 to 3.0 m/s. The arrangement of make-up air supply injection points include symmetrically located vents placed low in the spaced, an array of vents distributed from the floor to the ceiling, and asymmetrically located vents. Fire Dynamic Simulator version 4.06 is applied to simulate ten scenarios in a 30.5 m cubical domain with a fire source simulating a stack of pallets with an approximate peak heat release rate of 5 MW. Results show that make-up air supply velocities should be diffused such that little to no velocity effects reach the fire. Make-up air should be supplied to the fire symmetrically for the best chance of not disturbing the fire plume. Disturbing the fire and smoke plume results in a significant increase in the smoke production rate, as evidenced by a deeper smoke layer.

Similar content being viewed by others

References

J.A. Milke, “Smoke Management in Covered Malls and Atria,” SFPE Handbook of Fire Protection Engineering, 3rd edn., P.J. DiNenno (ed.), National Fire Protection Association, Quincy, MA, 2002.

NFPA 92B, Standard for Smoke Management Systems in Malls, Atria, and Large Areas. National Fire Protection Association, Quincy, MA, 2005.

G. Heskestad, “Engineering Relations for Fire Plumes,” Fire Safety Journal, vol. 7, 1984, pp. 25–32.

C. Beyler, “Fire Hazard Calculations for Large, Open Hydrocarbon Fires,” SFPE Handbook of Fire Protection Engineering, 3rd edn., P.J. DiNenno (ed.), National Fire Protection Association, Quincy, MA, 2002.

K.B. McGrattan and G.P. Forney, 2004a, Fire Dynamics Simulator—User's Manual, National Institute of Standards and Technology, NIST Special Publication 1019, Gaithersburg, MD, 2004.

K.B. McGrattan, H.R. Baum, R.G. Rehm, A. Hamins, and G.P. Forney, “Fire Dynamics Simulator – Technical Reference Guide,” National Institute of Standards and Technology, NIST Special Publication 1018. Gaithersburg, MD, 2004.

G.P. Fourney and K.B. McGrattan, “User's Guide for Smokeview Version 4—A Tool For Visualizing Fire Dynamics Simulator Data,” National Institute of Standards and Technology. NIST Special Publication 1017. Gaithersburg, MD, 2004.

Author information

Authors and Affiliations

Corresponding author

Additional information

1. Growth time refers to the time required for the heat release rate of the fire to increase to 1055 kW. The 150 s growth time is in the middle of the range of growth times noted in NFPA 92B for 1.5 m high stacks of pallets [2].

2. For the purpose of this paper, a ‘peak’ heat release rate is determined based on the maximum sustained heat release rate, neglecting the instantaneous spikes of the heat release rate.

Appendix A: Detailed Calculations

Appendix A: Detailed Calculations

Rights and permissions

About this article

Cite this article

Kerber, S., Milke, J.A. Using FDS to Simulate Smoke Layer Interface Height in a Simple Atrium. Fire Technol 43, 45–75 (2007). https://doi.org/10.1007/s10694-007-0007-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-007-0007-7