Abstract

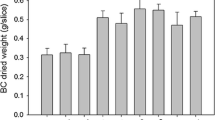

A rotating disk bioreactor with plastic composite support (PCS) as the solid support was evaluated for bacterial cellulose (BCel) production. Results demonstrated that BCel can be produced in a semi-continuous manner. The BCel productivity reached around 0.24 g/L/day and can be sustained for at least five consecutive runs. Scanning electron microscopy results confirmed that Gluconacetobacter can attach on the PCS surface, which eliminates the need of reinoculation. X-ray diffraction patterns and mechanical analysis of BCel produced from this semi-continuous process exhibited lower crystallinity (66.9 %) and mechanical property (Young's modulus of 372.5 MPa) when compared with the BCel obtained from static culture (crystallinity = 88.7 %, Young's modulus of 3,955.6 MPa). Both BCel samples possessed similar water content (98.66 vs. 99.04 %) and thermostability (around 346 °C). In conclusion, the PCS rotating disk bioreactor system can be used to produce BCel in pellicle form with enhanced productivity and, meanwhile, can be scaled up easily to meet commercial need.

Similar content being viewed by others

Abbreviations

- BCel:

-

Bacterial cellulose

- PCS:

-

Plastic composite support

- PCS-RDB:

-

PCS rotating disk bioreactor

- SS-RDB:

-

Stainless steel rotating disk bioreactor

- SC:

-

Static culture

- SEM:

-

Scanning electron microscopy

- XRD:

-

X-ray diffraction

References

Benziman M, Haigler CH, Brown RM, White AR, Cooper KM (1980) Cellulose biogenesis—polymerization and crystallization are coupled processes in Acetobacter-xylinum. Proc Natl Acad Sci Biol 77(11):6678–6682

Brown RM (2004) Cellulose structure and biosynthesis: what is in store for the 21st century? J Polym Sci Pol Chem 42(3):487–495. doi:10.1002/Pola.10877

Bungay HR, Serafica GC (1999) Production of microbial cellulose using a rotating disk film bioreactor. Us Patent US5955326, 1999/09/21

Bungay HR, Serafica GC (2000) Production of microbial cellulose. Us Patent US6071727, 2000/06/06

Cheng KC, Catchmark JM, Demirci A (2009) Enhanced production of bacterial cellulose by using a biofilm reactor and its material property analysis. J Biol Eng 3:12. doi:10.1186/1754-1611-3-12

Cheng KC, Demirci A, Catchmark JM (2010) Advances in biofilm reactors for production of value-added products. Appl Microbiol Biotechnol 87(2):445–456. doi:10.1007/s00253-010-2622-3

Cheng KC, Catchmark JM, Demirci A (2011) Effects of CMC addition on bacterial cellulose production in a biofilm reactor and its paper sheets analysis. Biomacromolecules 12(3):730–736. doi:10.1021/bm101363t

Deinema MH, Zevenhui L (1971) Formation of cellulose fibrils by gram-negative bacteria and their role in bacterial flocculation. Arch Mikrobiol 78(1):42–57

Haigler CH, White AR, Brown RM Jr, Cooper KM (1982) Alteration of in vivo cellulose ribbon assembly by carboxymethylcellulose and other cellulose derivatives. J Cell Biol 94(1):64–69

Ho KL, Pometto AL 3rd, Hinz PN, Dickson JS, Demirci A (1997a) Ingredient selection for plastic composite supports for L-(+)-lactic acid biofilm fermentation by Lactobacillus casei subsp. rhamnosus. Appl Environ Microbiol 63(7):2516–2523

Ho KLG, Pometto AL, Hinz PN (1997b) Optimization of L-(+)-lactic acid production by ring and disc plastic composite supports through repeated-batch biofilm fermentation. Appl Environ Microbiol 63(7):2533–2542

Hu Y, Catchmark JM (2010) Formation and characterization of spherelike bacterial cellulose particles produced by Acetobacter xylinum JCM 9730 strain. Biomacromolecules 11(7):1727–1734. doi:10.1021/bm100060v

Keshk S, Sameshima K (2006) The utilization of sugar cane molasses with/without the presence of lignosulfonate for the production of bacterial cellulose. Appl Microbiol Biotechnol 72(2):291–296. doi:10.1007/s00253-005-0265-6

Kim Y-J, Kim J-N, Wee Y-J, Park D-H, Ryu H-W (2007) Bacterial cellulose production by Gluconacetobacter sp. RKY5 in a rotary biofilm contactor. Appl Biochem Biotechnol 529–537. doi:10.1007/978-1-60327-181-3_44

Krystynowicz A, Czaja W, Wiktorowska-Jezierska A, Goncalves-Miskiewicz M, Turkiewicz M, Bielecki S (2002) Factors affecting the yield and properties of bacterial cellulose. J Ind Microbiol Biotechnol 29(4):189–195. doi:10.1038/sj.jim.7000303

Lin SP, Loira Calvar I, Catchmark J, Liu JR, Demirci A, Cheng KC (2013) Biosynthesis, production and applications of bacterial cellulose. Cellulose. doi:10.1007/s10570-013-9994-3

Nishi Y, Uryu M, Yamanaka S, Watanabe K, Kitamura N, Iguchi M, Mitsuhashi S (1990) The structure and mechanical-properties of sheets prepared from bacterial cellulose. 2. Improvement of the mechanical-properties of sheets and their applicability to diaphragms of electroacoustic transducers. J Mater Sci 25(6):2997–3001

Ohad I, Danon IO, Hestrin S (1962) Synthesis of cellulose by Acetobacter xylinum. V. Ultrastructure of polymer. J Cell Biol 12:31–46

Okiyama A, Motoki M, Yamanaka S (1992) Bacterial cellulose. 2. Processing of the gelatinous cellulose for food materials. Food Hydrocoll 6(5):479–487

Portal O, Clark WA, Levinson DJ (2009) Microbial cellulose wound dressing in the treatment of nonhealing lower extremity ulcers. Wounds 21(1):1–3

Roman M, Winter WT (2004) Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromolecules 5(5):1671–1677. doi:10.1021/Bm034519+

Schramm M, Hestrin S (1954) Factors affecting production of cellulose at the air liquid interface of a culture of Acetobacter-xylinum. J Gen Microbiol 11(1):123–129

Serafica G, Mormino R, Bungay H (2002) Inclusion of solid particles in bacterial cellulose. Appl Microbiol Biotechnol 58(6):756–760. doi:10.1007/s00253-002-0978-8

Song H-J, Li H, Seo J-H, Kim M-J, Kim S-J (2009) Pilot-scale production of bacterial cellulose by a spherical type bubble column bioreactor using saccharified food wastes. Korean J Chem Eng 26(1):141–146. doi:10.1007/s11814-009-0022-0

Sturcova A, Davies GR, Eichhorn SJ (2005) Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromolecules 6(2):1055–1061. doi:10.1021/bm049291k

Tanpichai S, Quero F, Nogi M, Yano H, Young RJ, Lindstrom T, Sampson WW, Eichhorn SJ (2012) Effective Young's modulus of bacterial and microfibrillated cellulose fibrils in fibrous networks. Biomacromolecules 13(5):1340–1349. doi:10.1021/bm300042t

Toyosaki H, Naritomi T, Seto A, Matsuoka M, Tsuchida T, Yoshinaga F (1995) Screening of bacterial cellulose-producing acetobacter strains suitable for agitated culture. Biosci Biotech Biochem 59(8):1498–1502

Trovatti E, Fernandes SM, Rubatat L, Freire CR, Silvestre AD, Neto C (2012) Sustainable nanocomposite films based on bacterial cellulose and pullulan. Cellulose 19(3):729–737. doi:10.1007/s10570-012-9673-9

Watanabe K, Tabuchi M, Morinaga Y, Yoshinaga F (1998) Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 5(3):187–200

Yamanaka S, Watanabe K, Kitamura N, Iguchi M, Mitsuhashi S, Nishi Y, Uryu M (1989) The structure and mechanical-properties of sheets prepared from bacterial cellulose. J Mater Sci 24(9):3141–3145

Acknowledgments

This work was sponsored in part by “Aim for the Top University Plan” of National Taiwan University and the National Science Council, Taiwan, under Contract No. 〈100-2313-B-002-057-MY2〉 and 〈102-2221-E-002-035-MY2〉. The authors are very grateful to Joint Center for Instruments and Researches, College of Bioresources and Agriculture at National Taiwan University, and Prof. An-I Yeh from Graduate Institute of Food Science Technology at National Taiwan University for his assistance with SEM, XRD measure and mechanical property analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, SP., Hsieh, SC., Chen, KI. et al. Semi-continuous bacterial cellulose production in a rotating disk bioreactor and its materials properties analysis. Cellulose 21, 835–844 (2014). https://doi.org/10.1007/s10570-013-0136-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0136-8