Abstract

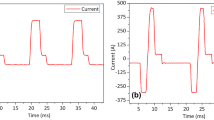

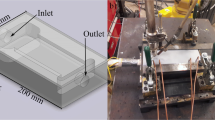

The wire melting phenomenon in alternating current gas metal arc welding (AC-GMAW) process should be carefully observed and analyzed since it is one of the most important representative characteristics of GMAW process. In this study, a new form of wire melting rate equation for AC-GMAW process is proposed based on energy conservation theory and arc physics. Using experimental data, the wire melting rate coefficients of AC-GMAW are obtained through nonlinear regression analysis. The wire melting rate is influenced not only by the current waveform, electrode polarity, and droplet size but also by the shape of the wire tip. That is, if the wire tip becomes more slender, arc heating has more influence on the wire melting. Using the wire melting rate proposed in this research, the uncertainty of calculating wire melting rate coefficients of AC-GMAW can be excluded comparing to existing method.

Similar content being viewed by others

References

Soderstrom EJ (2007) Gas metal arc-welding electrode heat-and- mass transfer mechanisms. Ph.D. Dissertation, Department of Metallurgical and Mechanical Engineering, Colorado School of Mines, Golden, Colorado, USA

Ueyama T, Tong H, Yazawa I, Hirami M, Kihara T, Nakata K, Ushio M (2004) Aluminum alloy sheet welding by the laser AC pulsed MIG hybrid process. Weld Int 18(5):345–350

Arif N, Chung H (2015) Alternating current-gas metal arc welding for application to thick plates. J Mater Process Technol 222:75–83

Singh D, Bhardwaj P, Yang YD, McLean A, Hasegawa M, Iwase M (2010) The influence of carbonaceous material on the melting behaviour of mould powder. Steel Research International 81(11):974–979

Arif N, Chung H (2014) Alternating current-gas metal arc welding for application to thin sheets. J Mater Process Technol 214(9):1828–1837

Andrade RC, Carvalho GCD (2013) Development of software for slicing 3D shell-like computational model and for off-line generation robot trajectory for building metallic parts by means of 564 layered gas metal arc welding. 22nd International Congress of 565 Mechanical Engineering (COBEM 2013), November 3-7, Ribeirão Preto, SP, Brazil

Park HJ, Kim DC, Kang MJ, Rhee S (2013) The arc phenomenon by the characteristic of EN ratio in AC pulse GMAW. Int J Adv Manuf Technol 66:867–875

Talkington JE (1998) Variable polarity gas metal arc welding. Masters Dissertation, Department of Material Science and Engineering, Ohio State University, Columbus, Ohio, USA

Vilarinho LO, Nascimento AS, Fernandes DB, Mota CAM (2009) Methodology for parameter calculation of VP-GMAW. Weld J 88(4):92–98

Lancaster JF (1986) The physics of welding, 2nd edn. Pergamon Press, New York, p. 214

Lesnewich A (1958) Control of melting rate and metal transfer in gas-shielded metal arc welding— part 1—control of electrode melting rate. Weld J 37(8):343–353

Allum CJ (1983) MIG. welding—time for a reassessment. Metal Construction 15:347–353

Richardson IM, Bucknall PW, Stares I (1994) The influence of power source dynamics on wire melting rate in pulsed GMA welding. Weld J 73:32–37

Harwig DD, Dierksheide JE, Yapp D, Blackman S (2006) Arc behavior and melting rate in the VP-GMAW process. Weld J 85(3):52–62

Lancaster JF (1986) The physics of welding, 2nd edn. Pergamon Press, New York, p. 250

Lesnewich A (1987) Commentary: mathematical modeling of melting rates for submerged-arc welding. Weld J 66(12):386–387

Greene D (2001) The Langmuir-Child law and the work function of tungsten. Laboratory report, Department of Physics and Engineering Physics, University of Saskatchewan. http://physics.usask.ca/~angie/p404/reports/exp3/p404-langmuirchild-lab3.doc. Accessed 17 September 2016

Zhu P, Lowke JJ, Morrow RHNR (1992) A unified theory of free burning arcs, cathode sheaths and cathodes. J Phys D Appl Phys 25(8):1221–1230

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, K., Chung, H. Wire melting rate of alternating current gas metal arc welding. Int J Adv Manuf Technol 90, 1253–1263 (2017). https://doi.org/10.1007/s00170-016-9384-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9384-8