Abstract

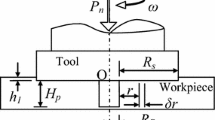

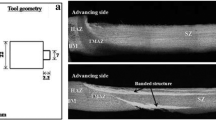

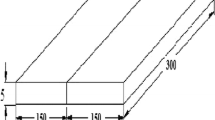

In this paper, the effect of friction stir welding (FSW) parameters on wear and deformation behavior of tungsten carbide (WC) tool employed in the welding of AISI 304 austenitic stainless steel (SS) is reported. In addition, the wear and deformation of the tool are also characterized. Three FSW parameters, namely shoulder diameter, tool rpm, and traverse speed each at three levels were considered. Experiments were performed as per Taguchi’s L9 orthogonal array to investigate the effect of these parameters on wear and plastic deformation of the tool. Wear at the pin root and bottom face of the pin attributed to diffusion and attrition mechanisms, respectively, were observed. Significant deformation of the tool was also observed during welding which caused bulging of the shoulder with an increased cone angle of the pin.

Similar content being viewed by others

References

Nandan R, DebRoy T, Bhadeshia HKDH (2009) Recent advances in friction stir welding—process, weldment structure and properties. Prog Mater Sci 53:980–1023

Threadgill PL, Leonard AJ, Shercliff HR, Withers PJ (2009) Friction stir welding of aluminium alloys. Int Mater Rev 54(2):49–93

Alberti N, Forcellese A, Fratini L, Gabrielli F (1998) Sheet metal forming of titanium blanks using flexible media. CIRP Ann Manuf Technol 47(1):217–244

Çam G (2011) Friction stir welded structural materials beyond Al-alloys. Int Mater Rev 56(1):1–48

Park SHC, Sato YS, Kokawa H, Okamoto K, Hirano S, Inagaki M (2003) Rapid formation of the sigma phase in 304 stainless steel during friction stir welding. Scr Mater 49(12):1175–1180

Reynolds AP, Tang W, Gnaupel-Herold T, Prask H (2003) Structure, properties, and residual stress of 304L stainless steel friction stir welds. Scr Mater 48(9):1289–1294

Rai R, De A, Bhadeshia HKDH, DebRoy T (2011) Review: friction stir welding tools. Sci Technol Weld Join 16(4):325–342

Park S, Sato Y, Kokawa H, Okamoto K, Hirano S, Inagaki M (2009) Boride formation induced by pcBN tool wear in friction-stir-welded stainless steels. Metall Mater Trans A 40A(3):625–636

Gan W, Li ZT, Khurana S (2007) Tool materials selection for friction stir welding of L80 steel. Sci Technol Weld Join 12(7):610–613

Liyanage T, Kilbourne J, Gerlich AP, North TH (2009) Joint formation in dissimilar Al alloy/steel and Mg alloy/steel friction stir spot welds. Sci Technol Weld Join 14(6):500–508

Weinberger T, Enzinger N, Cerjak H (2009) Microstructural and mechanical characterisation of friction stir welded 15-5PH steel. Sci Technol Weld Join 14(3):210–215

Reynolds AP, Tang W, Posada M, DeLoach J (2003) Friction stir welding of DH36 steel. Sci Technol Weld Join 8(6):455–460

Klingensmith SJ, Dupont N, Marder AR (2005) Microstructural characterization of a double-sided friction stir weld on a superaustenitic stainless steel. WELDING JOURNAL, 77 s–85s]

Meran C, Kovan V, Alptekin A (2007) Friction stir welding of AISI 304 austenitic stainless steel. Mater Werkst 38:829–835

Fujii H, Sun Y, Kato H, Nakata K (2010) Welded pure Ti joints. Mater Sci Eng A 527:3386–3391

Fernandez GJ, Murr LE (2004) Characterization of tool wear and weld optimization in the friction-stir welding of cast aluminum 359 + 20 % SiC metal-matrix composite. Mater Charact 52:65–75

Liu HJ, Feng JC, Fujii H, Nogi K (2005) Wear characteristics of a WC–Co tool in friction stir welding of AC4AC30 vol% SiCp composite. Int J Mach Tools Manuf 45:1635–1639

Bentley AR, Hogwood MC (1992) The effect of mechanical deformation and heat treatment on the microstructural characteristics of two tungsten heavy alloys. Tungsten and Tungsten Alloys Conference 419–429

Weinberger T, Kosha S, Fuhrer B, Ensinger N (2008) Analysis of tool wear and failure mechanism during friction stir welding of steel. 7th International Friction Stir Welding Symposium, Session 9B, Awaji Island

Thompson B, Babu SS (2010) Tool degradation characterization in the friction stir welding of hard metals. Weld Res 89:256s–261s

Saeid T, Abdollah-zadeh A, Assadi H, Malek Ghaini F (2008) Effect of friction stir welding speed on the microstructure and mechanical properties of a duplex stainless steel. Mater Sci Eng A 496(1–2):262–268

Lakshminarayanan AK, Balasubramanian V (2010) An assessment of microstructure, hardness, tensile and impact strength of friction stir welded ferritic stainless steel joints. Mater Des 31(10):4592–4600

Lou D, Hellman J, Luhulima D, Liimatainen J, Lindroos VK (2003) Interactions between tungstencarbide (WC) particulates and metal matrix in WC-reinforced composites. Mater Sci Eng A 340(1–2):155–162

Thakur D, Ramamoorthy B, Vijayaraghavan L (2008) Influence of different post treatments on tungstencarbide–cobalt inserts. Mater Lett 62(28):4403–4406

Trent E, Wright P (2000) Metal cutting. Butterworth, Boston, pp 175–202

Santhanam AT (2003) Carbides, cemented. Kirk Othmer Encycl Chem Technol. doi:10.1002/0471238961.0305130519011420.a01.pub2

Lienert TJ, Stellwag WL, Grimmett BB Jr, Warke RW (2003) Friction stir welding studies on mild steel. Weld J 82:1s–9s

Ahmed R, Yu H, Edwards L, Santisteban JR (2007) Influence of vacuum heat treatment on the residual stress of thermal spray cermet coatings. Proceedings of the World Congress on Engineering 2007 Vol II WCE 2007, July 2–4, 2007, London, UK

Meran C, Canyurt OE (2010) Friction stir welding of austenitic stainless steels. J Achiev Mater Manuf Eng 43(1):432–439

Thomas WM, Threadgill PL, Nicholas ED The feasibility of friction stir welding steel. Available:http://www.twi.co.uk/j32k/protected/band_8/spwmtfeb99.html

Melendez M, Tang W, Schmidt C, McClure JC, Nunes AC, Murr LE (2003) Tool forces developed during friction stir welding. NASA unclassified technical report No E-14070; NAS 1.15:212510; NASA/TM-2003-212510

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siddiquee, A.N., Pandey, S. Experimental investigation on deformation and wear of WC tool during friction stir welding (FSW) of stainless steel. Int J Adv Manuf Technol 73, 479–486 (2014). https://doi.org/10.1007/s00170-014-5846-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5846-z