Abstract

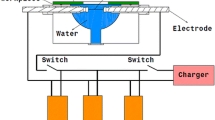

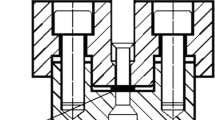

Superplastic forming has been considered as an attractive process in the automotive and aerospace industries. However, the disadvantages of slow forming rate, high-temperature requirement, poor thickness distribution, and expensive base material have hindered its widespread use for high production volume. In this paper, the non-superplastic grade of 5083 aluminum alloy (AA5083) sheets with thickness of 3 mm was employed in a superplastic-like forming process, which is a combination of drawing (mechanical pre-forming) and superplastic forming (blow forming). Experimental trials were conducted to verify the possibility of improving the forming rate and lowering the process temperature. The blank was firstly pre-formed during the mechanical pre-forming phase. As a result, some part of material along the flange area was introduced inside the deformation cavity in advance of the blow forming phase. Secondly, argon gas was applied on the sheet, which would be deformed to come into contact with the inner die surface at the end of pressure cycle. It took only 8 min for the blow forming phase, and the process achieved an almost fully formed part at 400°C. The minimum thickness occurred at the inward corners, and the maximum thinning of the formed part was 54%. Grain growth and cavitation were found from the microstructure observations.

Similar content being viewed by others

References

Barnes AJ (2007) Superplastic forming 40 years and still growing. J Mater Eng Perform 16:440–454

Friedman PA, Luckey SG, Copple WB, Allor R, Miller CE, Young C (2004) Overview of superplastic forming research at ford motor company. J Mater Eng Perform 13:670–677

Giuliano G (2006) Analysis of forming limit diagram for superplastic materials. Int J Adv Manuf Technol 31:244–246

Patankar SN, Lim CT, Tan MJ (2000) Superplastic forming of duplex stainless steel. Metall Mater Trans A 31A:2394–2396

Patankar SN, Tan MJ (1997) “Superplastic forming” of commercial purity aluminum. Scr Mater 38:145–148

Kim WJ, Park JD, Yoon US (2008) Superplasticity and superplastic forming of Mg-Al-Zn alloy sheets fabricated by strip casting method. J Alloy Compd 464:197–204

Luo Y, Miller C, Luckey G, Friedman P, Peng Y (2007) On practical forming limits in superplastic forming of aluminum sheet. J Mater Eng Perform 16:274–283

Xun YW, Tan MJ (2000) Applications of superplastic forming and diffusion bonding to hollow engine blades. J Mater Process Technol 99:80–85

Chockalingam KSK, Neelakantan M, Devaraj S, Padmanabhan KA (1985) On the pressure forming of two superplastic alloys. J Mater Sci 20:1310–1320

Verma R, Friedman PA, Ghosh AK, Kim S, Kim C (1996) Characterization of superplastic deformation behavior of a fine grain 5083 Al alloy sheet. Metall Mater Trans A 27A:1889–1898

Kleiner M, Geiger M, Klaus A (2003) Manufacturing of lightweight components by metal forming. CIRP Ann Manuf Technol 52:521–542

Osada K (1997) Commercial applications of superplastic forming. J Mater Process Technol 68:241–245

Ingelbrecht CD (1985) Prediction of the optimum pressure cycle for the superplastic forming of hemispheres from Ti-6Al-4 V sheet. J Mater Sci Lett 4:1021–1025

Sorgente D, Scintilla L, Palumbo G, Tricarico L (2010) Blow forming of AZ31 magnesium alloy at elevated temperatures. Int J Mater Form 3:13–19

Luo Y, Luckey SG, Copple WB, Friedman PA (2008) Comparison of advanced spf die technologies in the forming of a production panel. J Mater Eng Perform 17:142–152

Luo Y, Luckey SG, Friedman PA, Peng Y (2008) Development of an advanced superplastic forming process utilizing a mechanical pre-forming operation. Int J Mach Tools Manuf 48:1509–1518

Menezes P, Kumar K, Kishore KS (2009) Influence of friction during forming processes—a study using a numerical simulation technique. Int J Adv Manuf Technol 40:1067–1076

Park D, Yarlagadda P (2008) Effects of punch load for elliptical deep drawing product of automotive parts. Int J Adv Manuf Technol 35:814–820

Wei Z, Zhang ZL, Dong XH (2006) Deep drawing of rectangle parts using variable blank holder force. Int J Adv Manuf Technol 29:885–889

Liu J, Tan MJ, Jarfors AEW, Yingyot AUL, Castagne S (2009) Formability in AA5083 and AA6061 alloys for light weight applications. Mater Des. doi:10.1016/j.matdes.2009.10.052

Pilling J, Ridley N (1989) Superplasticity in crystalline solids. The Institute of Metals, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Tan, MJ., Aue-u-lan, Y. et al. Superplastic-like forming of non-superplastic AA5083 combined with mechanical pre-forming. Int J Adv Manuf Technol 52, 123–129 (2011). https://doi.org/10.1007/s00170-010-2729-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2729-9